33

SPM Flex Gas Detector

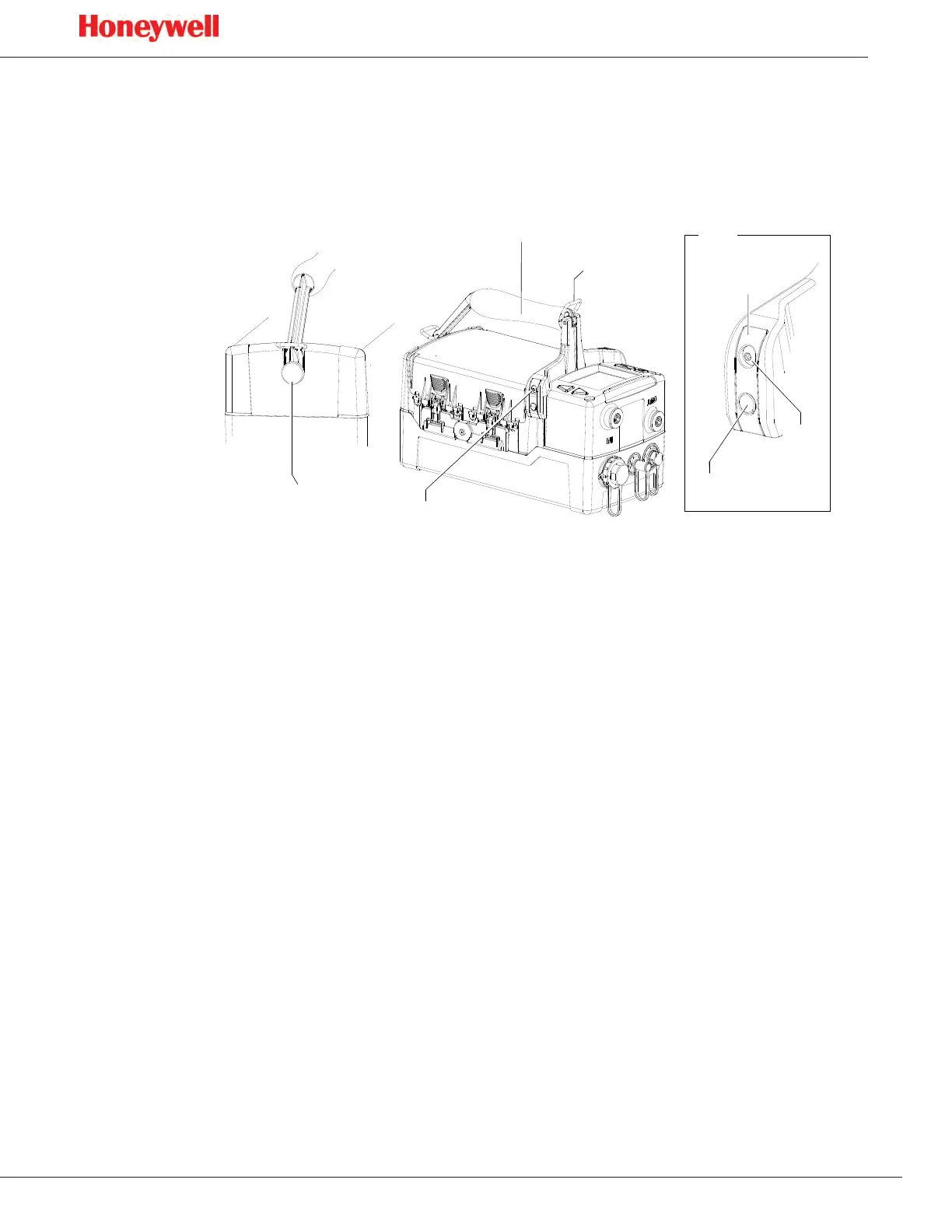

Converting a detector from fixed to portable

A fixed-installation SPM Flex gas detector can be converted for portable

applications following this procedure:

1. Remove the detector from its mounting bracket (see “Standard mounting bracket”

on page 29 or “Backward-compatible mounting bracket” on page 30).

Handle Shoulder

strap

ring (2)

Thumbscrew

Hex screw (2)

Bracket

pin

Hex

screw

Snap-in

bracket

Detail

Figure 24. Handle removal

2. Slide the handle into place as shown above.

3. Secure the snap-in bracket on the bracket pin with one of the 1/8-inch hex screws,

as shown in the detail illustration.

4. Repeat on the other side of the detector.

5. The handle is hinged to allow access to the Chemcassette cartridge compartment.

Lower the handle and secure it with the thumbscrew.

6. If the optional shoulder strap is to be used, attach its spring clips to each of the

rings on the detector’s handle. The strap must be laundered before use in clean-

room applications.

In-line filters

For most gases, it is imperative to use an external filter to protect the tubing and

the detector from contamination� Use particulate filter part number 780248 for

non-corrosive gases� Use filter 1991-0147 for corrosive gases� Refer to “Detectable

Gases” on page 62 for specific gases� Replace the filters after every 3 to 6

months of operation, depending on the cleanliness of the installation environment�

Note that filters are not used with diisocyanates, hydrazine, ozone, or hydrogen

peroxide so regular maintenance cleaning is especially important for detectors

exposed to those gases�

Loading...

Loading...