60

SPM Flex Gas Detector

Checking for system leaks

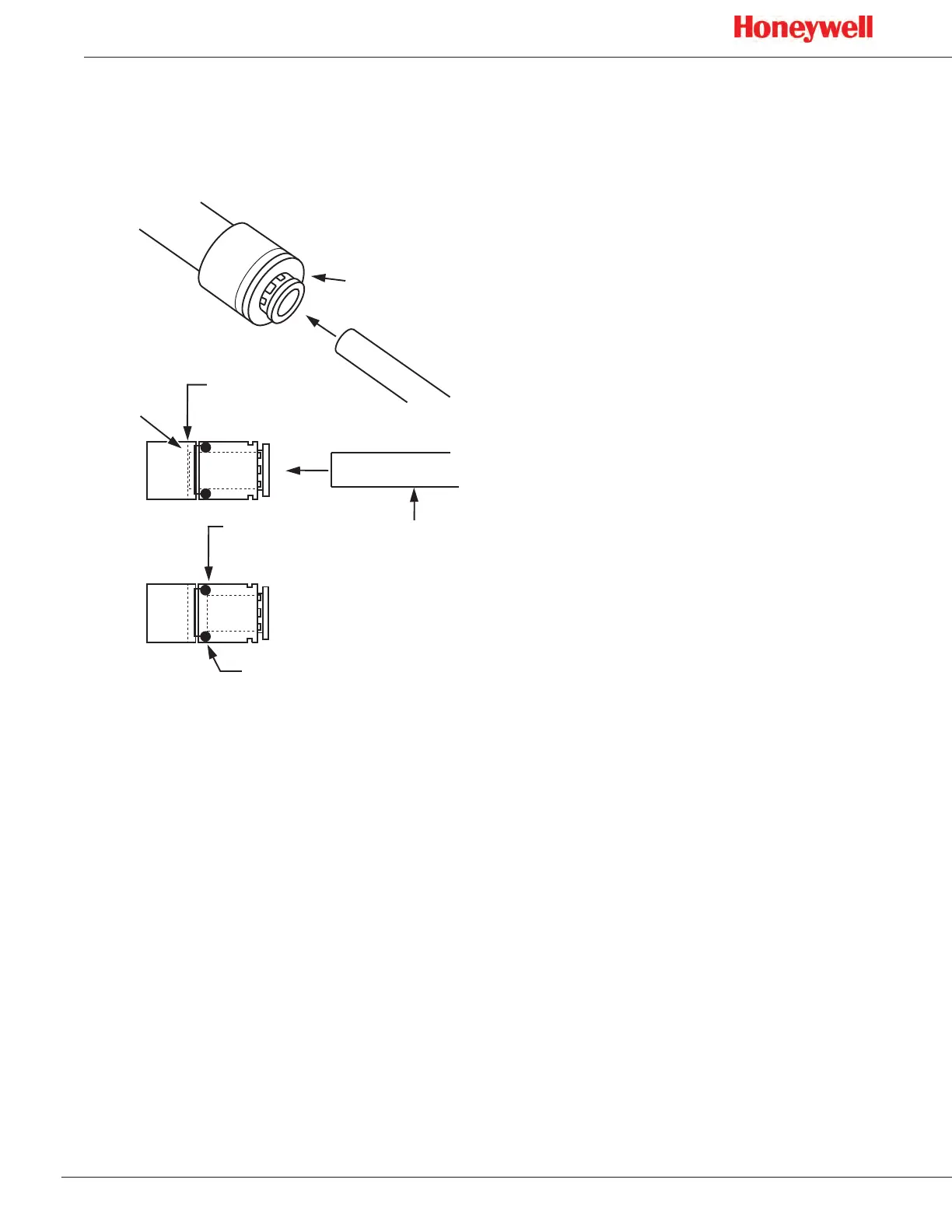

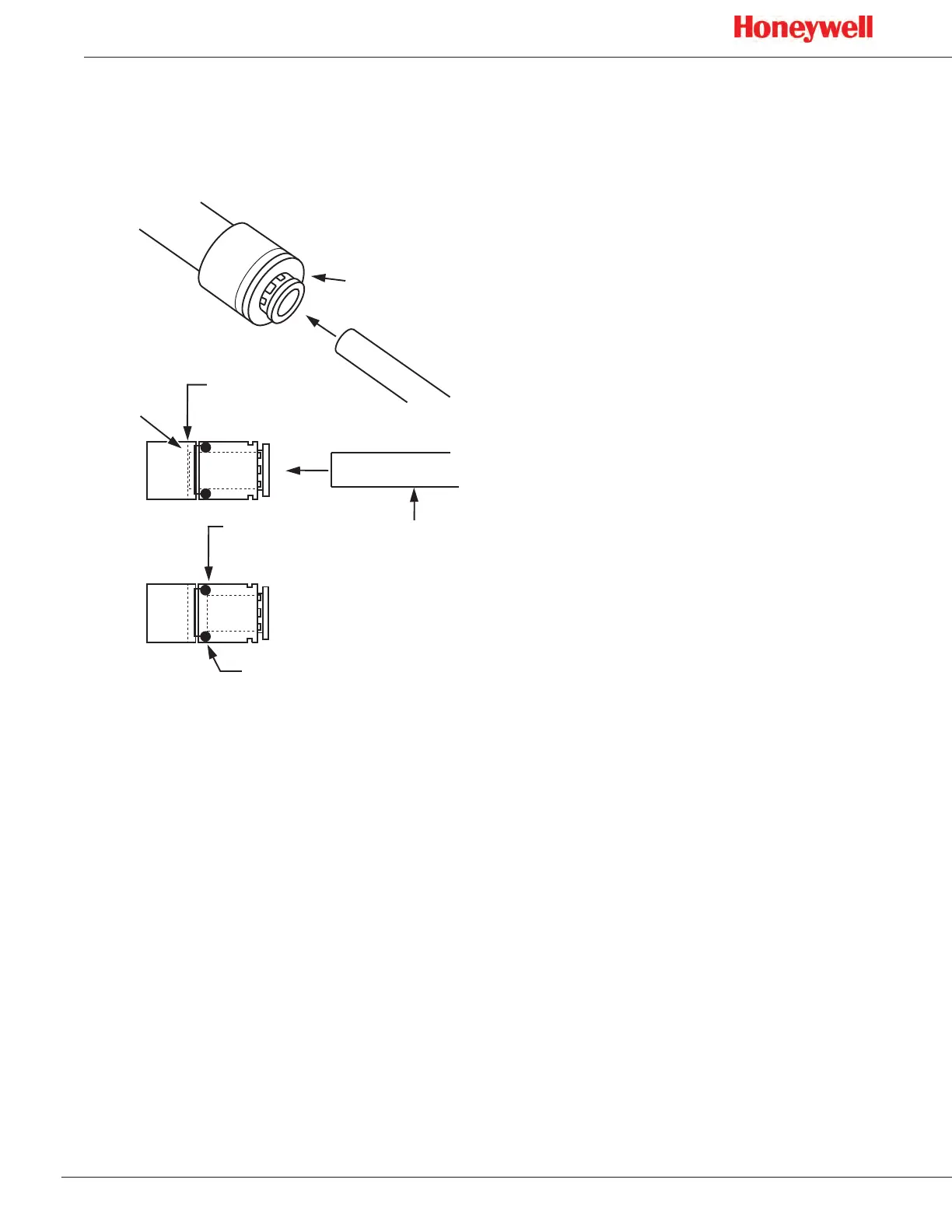

If the system uses the sampling wand or sample tubing, verify that the tubing is

correctly seating in the detector’s push fitting as shown in this figure�

Grey locking ring

Tubing

stop

Correct depth

(fully inserted)

TubingIncorrect depth

(not fully inserted)

O-ring (cross section)

Figure 38. Properly seating tubing in push fittings

In the Review menu, navigate to the Additional Status option� Plug the inlet

tube� If the system is not leaking, the detector will display a fault after about 30

seconds� This may take longer if the sampling wand is attached and possibly as

long as 2 minutes if the test gas must travel through a lengthy sample tube�

If a fault is not issued, observe the flow reading on the detector’s display� If it

stabilizes at more than the maximum rate shown in the “Sample Analysis Flow

Rate” column of “Detectable Gases” on page 62, there is likely a system leak�

Contact Honeywell Analytics’ Service Department�

Loading...

Loading...