20

SPM Flex Gas Detector

Wiring and tubing

• The safety of any system incorporating the SPM Flex gas detector is

the responsibility of the assembler of the system�

• Position a permanently-installed SPM Flex gas detector so that it does

not interfere with access to the dedicated circuit breaker�

• Use only the specified power adaptor/charger (see “Specifications” on

page 63)�

• Use the power adaptor/charger only in indoor applications�

CAUTION

!

Do not wire relays and 4-20 mA in the same wire bundle�

NOTE

Typical fixed installation topologies

The SPM Flex gas detector has flexible installation options that allow the user to

select the one most suitable for a specific application� The detector is supplied

with weather-sealed connectors for power, Ethernet, and communications

(for relays or 4-20 mA)� The Ethernet port can be replaced with an appropriate

connection in accordance with local codes (allowing the user to wire directly to

the terminal block)� Install each detector near a dedicated circuit breaker�

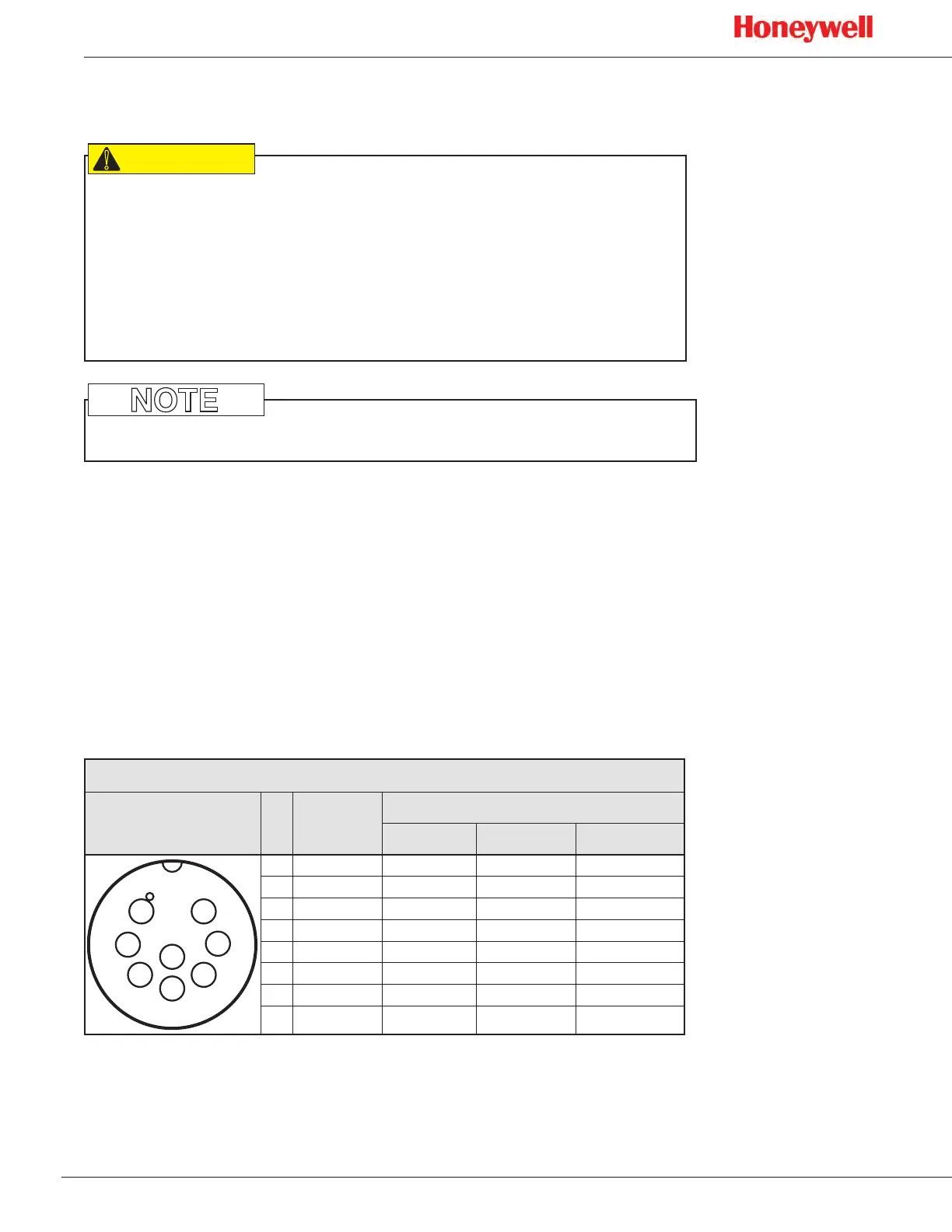

This table shows the default wiring configuration for the IP-rated communication

connector when installed by Honeywell Analytics� The relays are labeled for the

factory default but the configuration can be modified to have a single alarm and

separate faults�

Relay/mA Terminal Connections

Front View No. Color

Relay/mA Terminal Connections

mA Sink mA Source Isolated mA*

1

2

3

5

4

6

7

8

1 Red

Alarm2 NO Alarm2 NO Alarm2 NO

2 Black

Alarm2 COM Alarm2 COM Alarm2 COM

3 White

Alarm1 NO Alarm1 NO Alarm1 NO

4 Green

Alarm1 COM Alarm1 COM Alarm1 COM

5 Brown

Fault NO Fault NO Fault NO

6 Blue

Fault COM Fault COM Fault COM

7 Yellow

24 VDC + 4-20 mA - 4-20 mA -

8 White/Black

4-20 mA + 24 VDC - 4-20 mA +

*default pin configuration

Electrical connection is made via conduit directly to ports or via the connector

(see Figure 1, “Connectors and ports” on page 10� The terminals used are

suitable for conductors of 20 to 14 AWG (0�8 to 1�6 mm dia�)�

Loading...

Loading...