26 - English

Centrifugal clutch

The centrifugal clutch has the task of transferring the power from the engine to the cutting equipment’s

drive axle. As the name implies, it works according to a centrifugal principle.

This means the clutch’s friction shoes are thrown outwards towards the clutch drum at a certain engine

speed. When the friction against the drum is sufficiently great it drives the drive shaft at the same speed

as the engine.

Some slipping occurs between the clutch and the clutch drum when accelerating as well as in the

reversed situation when the cutting equipment jams. Thereby preventing abnormal load changes on the

crankshaft.

The engagement speed has been carefully tested so that the engine can idle without the cutting

equipment’s drive shaft rotating.

7.5 Dismantling the centrifugal clutch

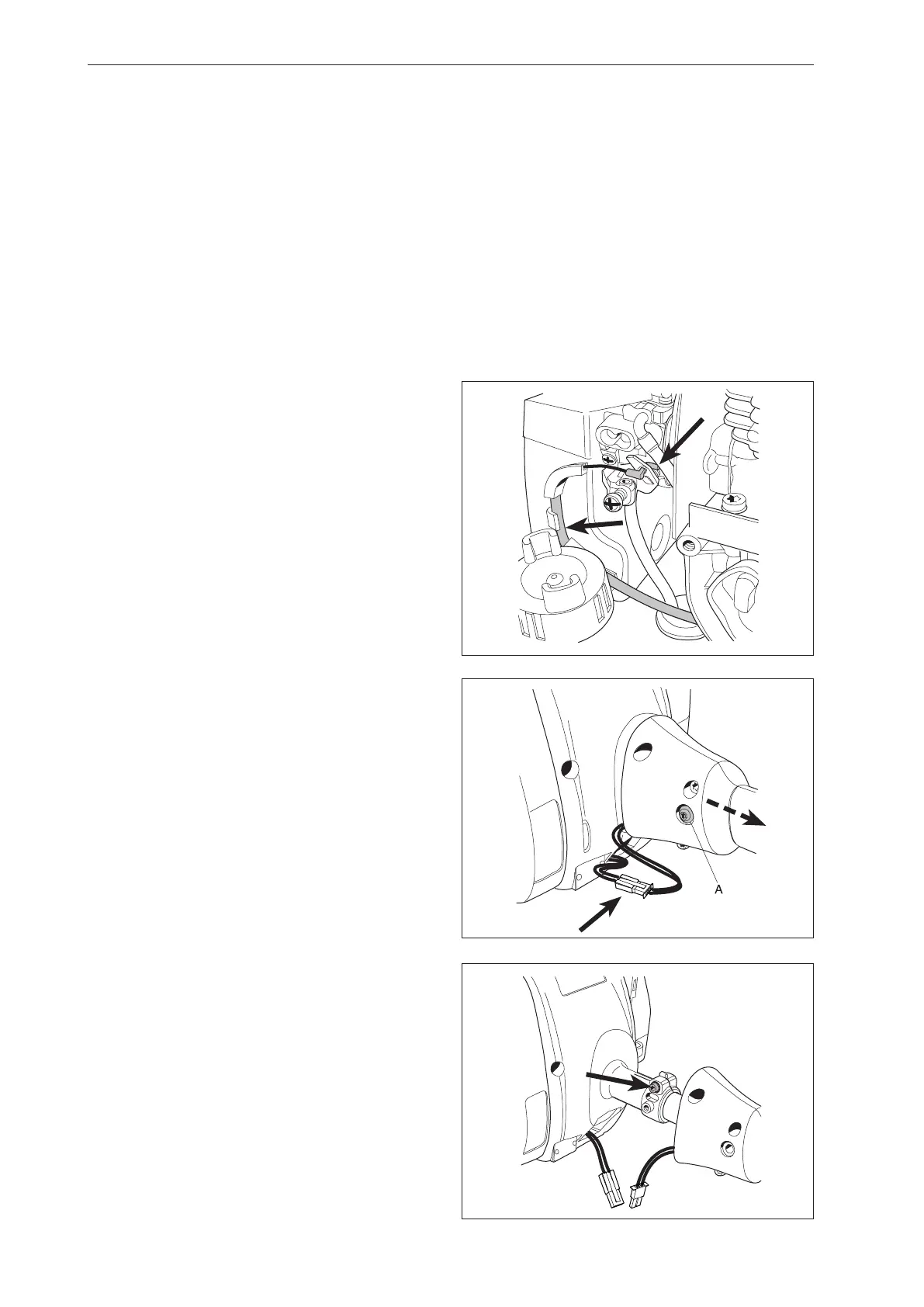

1

Unhook the throttle cable from the carburettor and

remove it from the guides in the carburettor cover.

See figure 13.

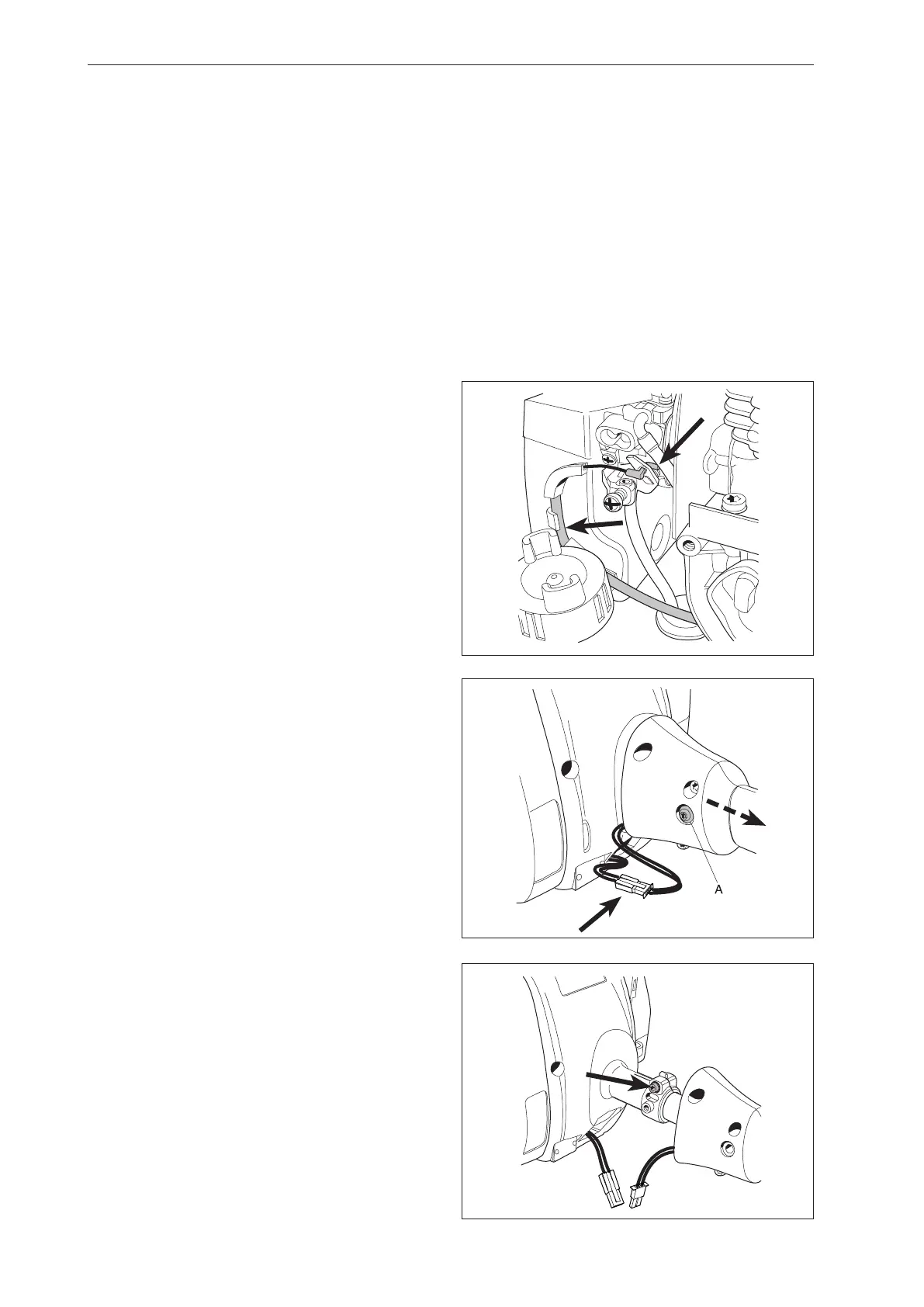

Fig 14

Fig 13

Fig 15

2

Carefully pull out the short-circuit cable from the

throttle handle, and separate the connector.

Remove the screw (A) on the side of the throttle

handle, and push the throttle forward onto the

shaft. See figure 14.

3

Loosen the screws and remove the shaft from the

engine. See figure 15.

The following components must be dismantled for

the centrifugal clutch to be accessible.

• The starter cover with half of the cover over the

muffler.

Repair Instructions

Loading...

Loading...