English - 45

5

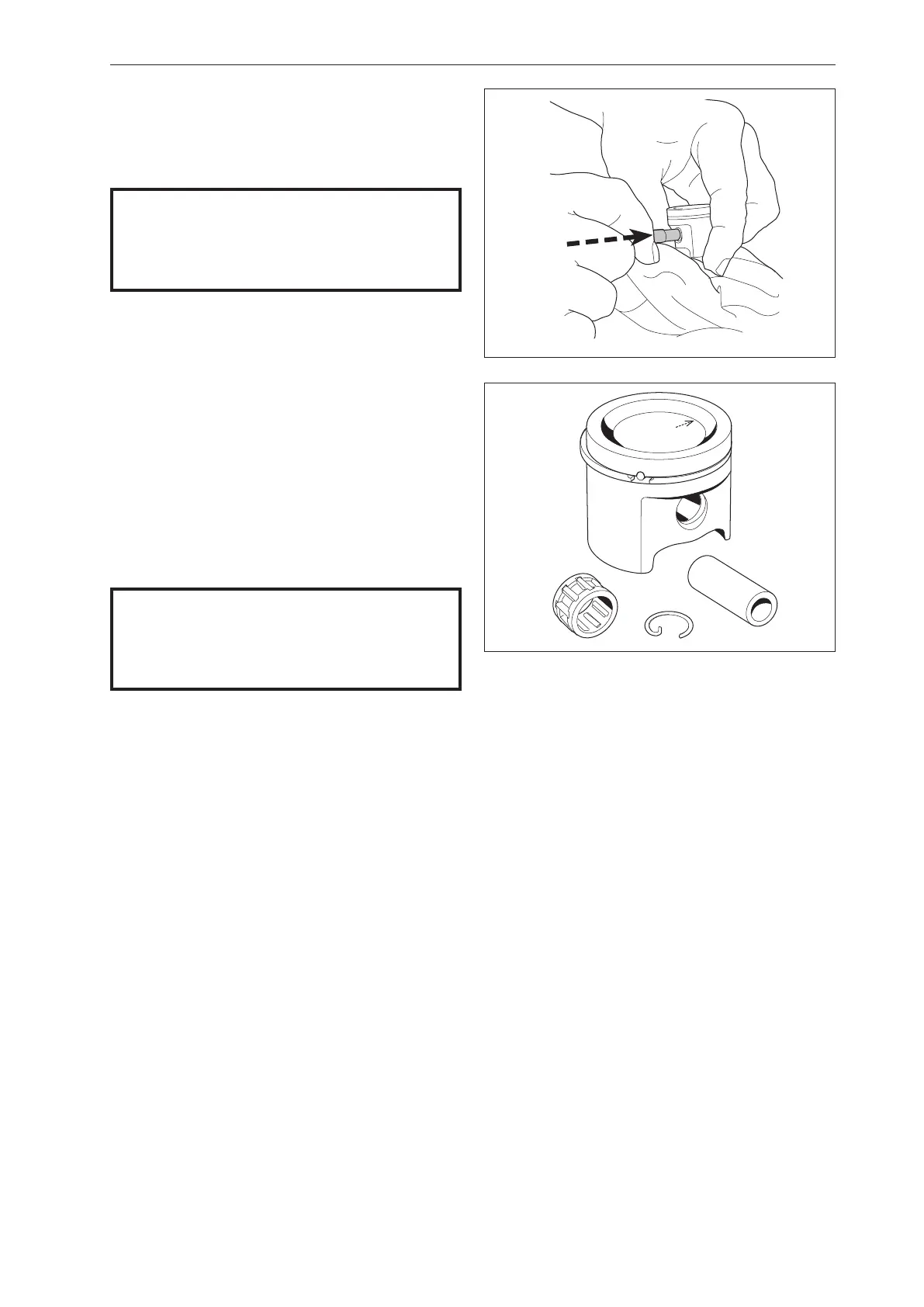

Push the gudgeon pin from the piston using punch

no. 502 52 42-01. See figure 62.

If the pin is too tight, carefully warm the piston.

7.19 Cleaning and inspection

After dismantling, clean the individual components:

1. Scrape carbon deposits from the top of the

piston.

2. Scrape carbon deposits from the cylinder’s

combustion chamber.

3. Scrape carbon deposits from the cylinder’s

exhaust port.

4. Wash all the components. Remove any

remaining adhesive film from the cylinder and

carburettor distance piece.

5. Inspect the different components for damage

and wear.

Check the piston and cylinder for seizure damage

and wear. Also see the “Analysis and actions”

section.

Check the piston ring for wear and damage. Also

see the “Analysis and actions” section.

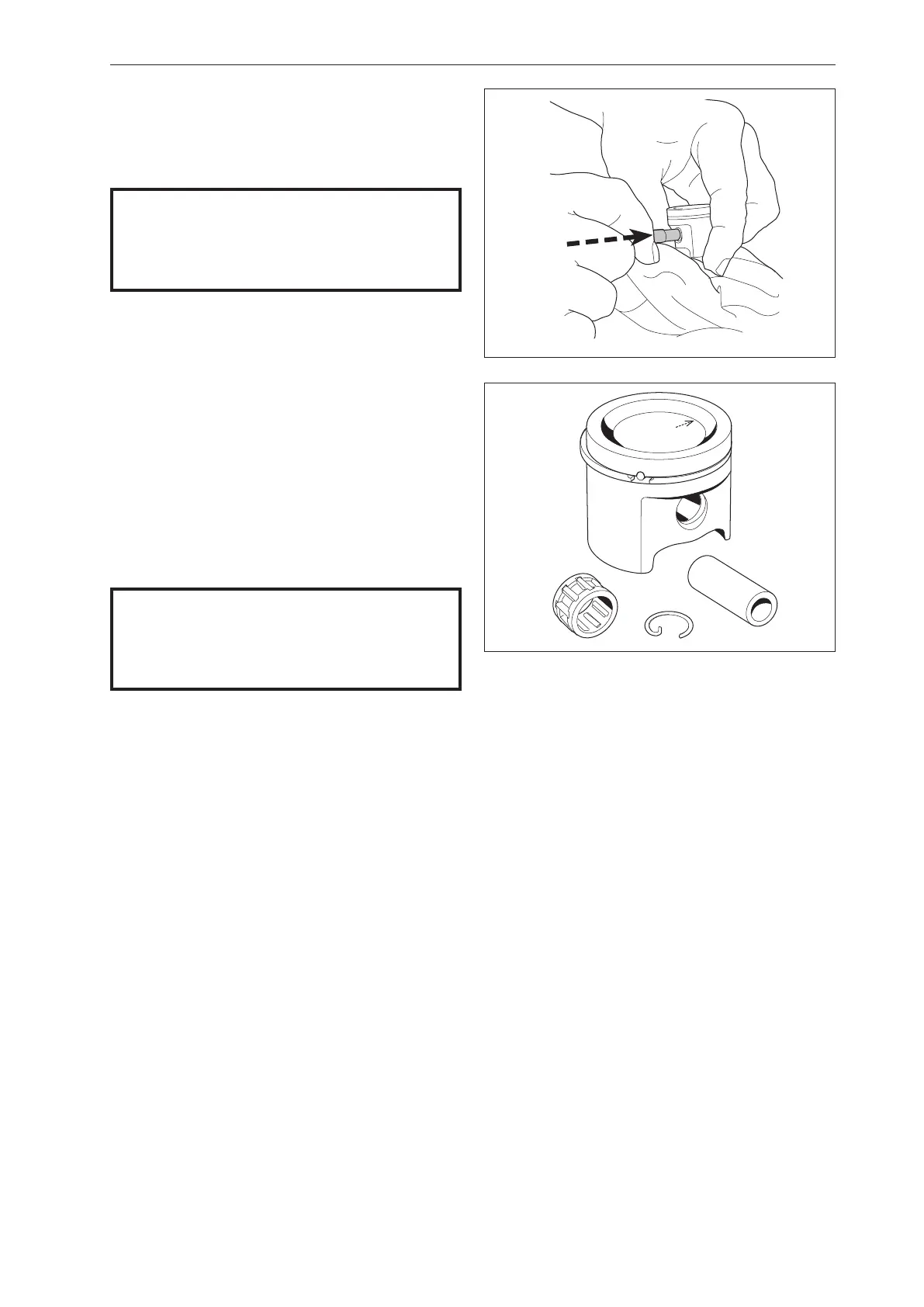

Check the gudgeon pin.

• If it has blued, it must be replaced.

• If the piston moves too easily both the piston and

the gudgeon pin must be replaced.

Check the needle bearing. If it is discoloured or

damaged, it must be replaced.

Check the circlips. If they exhibit cracks or are

discoloured (caused by overheating), they must be

replaced.

NOTE!

Scrape carefully with not too sharp a tool

so as not to damage the soft aluminium

parts.

NOTE!

Make sure the spacer washers on each

side of the needle bearing are not

misplaced.

Fig 62

Fig 63

Cylinder and piston

Loading...

Loading...