ArcGlide THC Instruction Manual 806450 207

4 – Maintenance

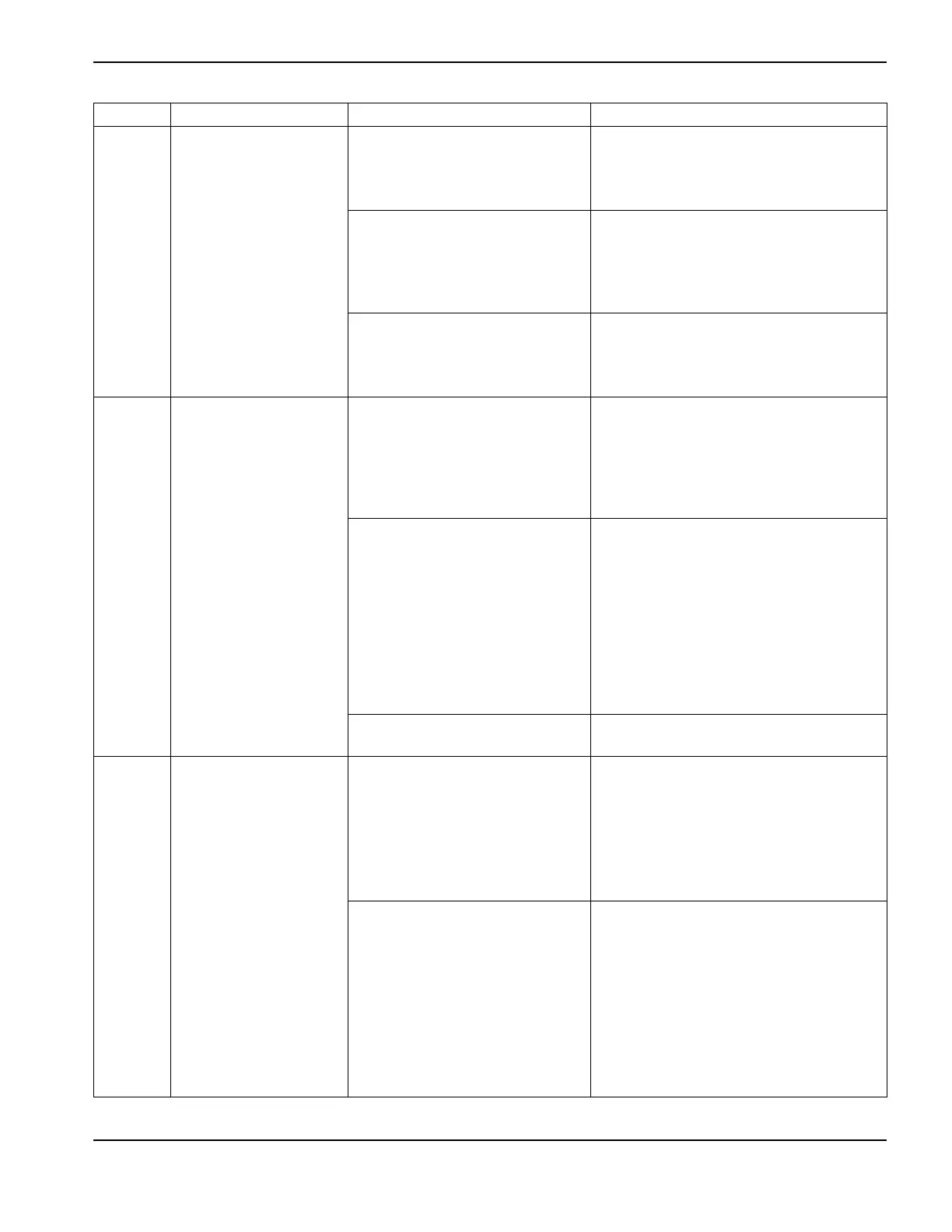

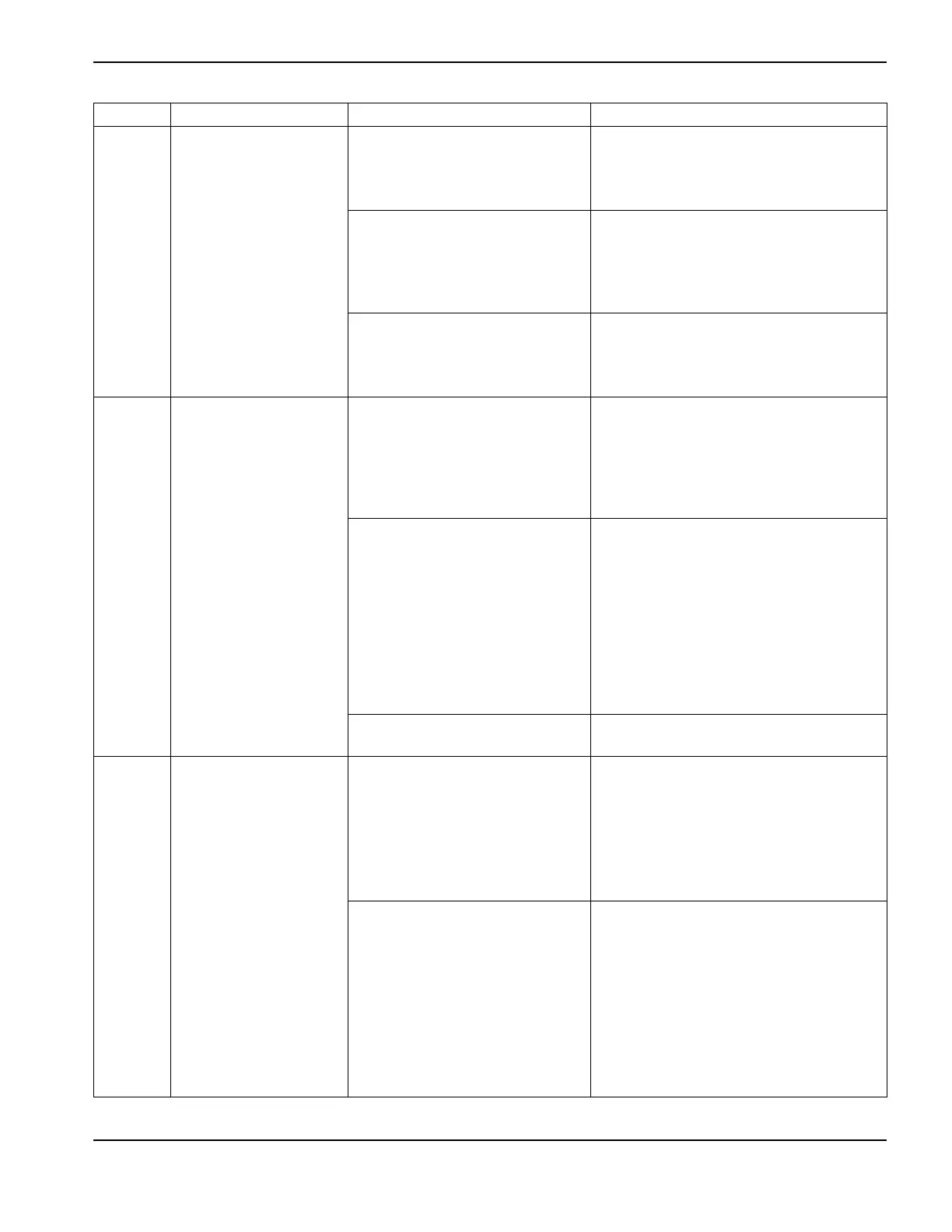

33 LOST HMI HYPERNET

The HMI lost the

Hypernet connection

after it was established.

• The HMI is not turned ON. • Verify that the HMI is turned ON.

• An Ethernet cable is unplugged

or damaged.

• Examine the Ethernet cables connecting

to HMI to the control module, and to the

Ethernet switch.

• Examine the Ethernet cables for

damage.

• The Ethernet switch is not

turned ON correctly.

• Verify that the Ethernet switch is

correctly turned ON.

• Verify that all related units are turned ON

and addressed to the unit number.

34 ENCODER

OVERFLOW

The internal position

counter has counted

beyond its maximum

value.

• There is electrical noise on the

lifter cable or the cable is not

correctly shielded or grounded.

• The motor drive board in the

control module is faulty.

• Verify that the lifter cable is correctly

shielded and grounded to the control

module and to the lifter assembly.

• Verify that the system is correctly

grounded.

• There is an incorrect encoder

setting in either the control

module or in the CNC.

• The encoder on the motor is

faulty.

• Look at the encoder counts in the

control module or CNC. Verify that the

settings are the default settings. See

ArcGlide axis setup parameters on

page 121.

• Monitor the operation of the motor and

encoder from the diagnostic screen of

the CNC or at control module (See

Screen 6 – Outputs from the lifter

control board on page 139).

• The lifter interface cable is

damaged.

• Examine the lifter interface cable for

damage.

35 ENCODER

UNDERFLOW

The internal position

counter has counted

below its minimum value.

• There is electrical noise on the

lifter cable or the cable is not

correctly shielded or grounded.

• The encoder on the motor is

faulty.

• The motor drive board in the

control module is faulty.

• Verify that the lifter cable is correctly

shielded and grounded to the control

module and to the lifter assembly.

• Verify that the system is correctly

grounded.

• There is an incorrect encoder

setting in either the control

module or in the CNC.

• Look at the encoder counts in the

control module or CNC. Verify that the

settings are the default settings. See

ArcGlide axis setup parameters on

page 121.

• Monitor the operation of the motor and

encoder from the diagnostic screen of

the CNC or at control module (See

Screen 6 – Outputs from the lifter

control board on page 139).

Error Description Causes Solutions

Loading...

Loading...