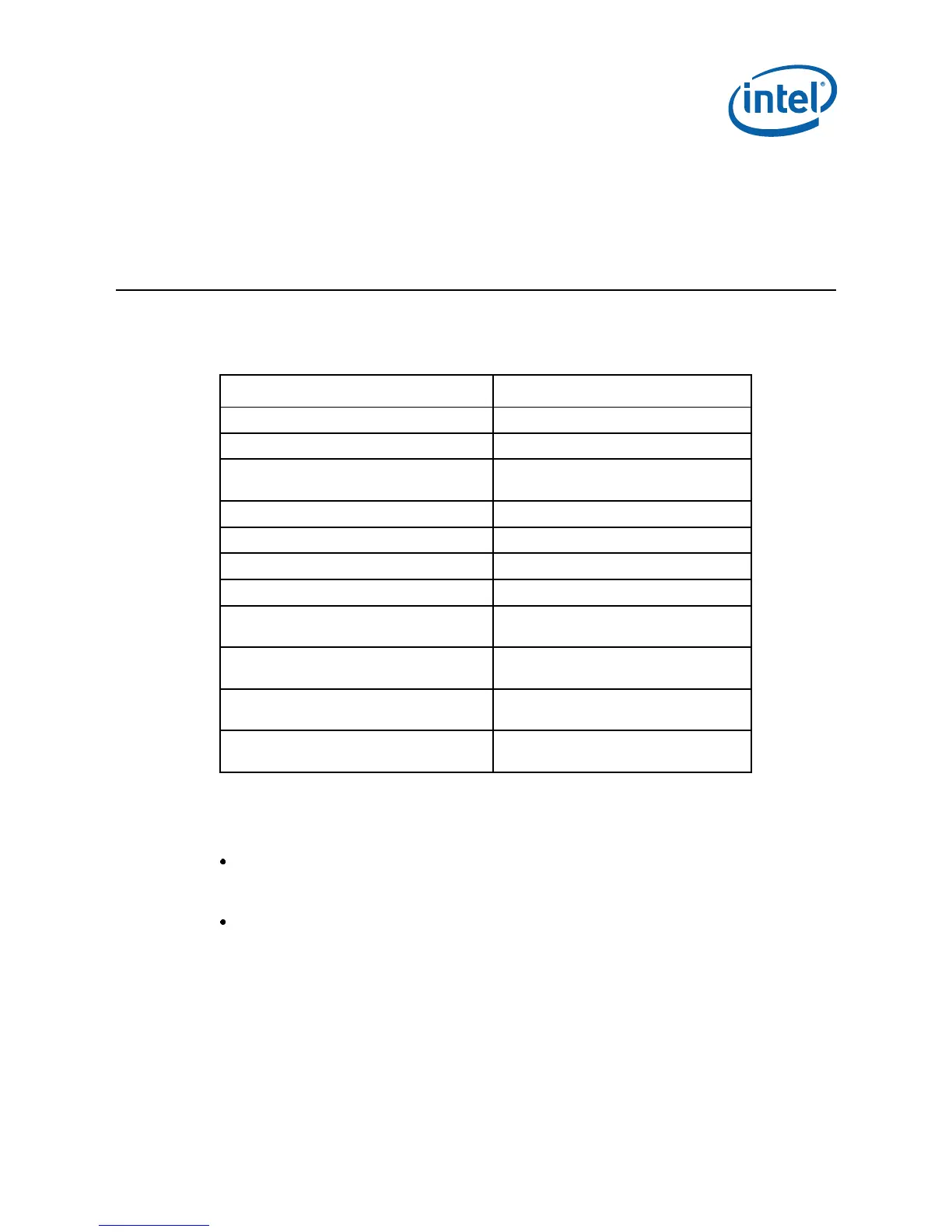

Fan Performance for Reference Design

Thermal and Mechanical Design Guidelines 125

Appendix GFan Performance for

Reference Design

The fan power requirements for proper operation are given Table 7-6.

Table

7-6. Fan Electrical Performance Requirements

Requirement Value

Maximum Average fan current draw 1.5 A

Fan start-up current draw 2.2 A

Fan start-up current draw maximum

duration

1.0 second

Fan header voltage 12 V ±5%

Tachometer output 2 pulse per revolution

Tachometer output signal Open-collector (open-drain)

PWM signal input frequency 21 kHz to 28 kHz

PWM signal pull up in fan 3.3 V (recommended max)

5.25 V (absolute max)

PWM signal current source Imax = 5 mA

(short circuit current)

PWM signal maximum voltage for logic

low

VIL = 0.8 V

PWM compliant function RPM must be within spec for specified

duty cycle

In addition to comply with overall thermal requirements (Sections 5.1.1 and 6.2), and

the general environmental reliability requirements (Sections 5.2 and 6.3) the fan

should meet the following performance requirements:

Mechanical wear out represents the highest risk reliability parameter for fans. The

capability of the functional mechanical elements (ball bearing, shaft, and tower

assembly) must be demonstrated to a minimum useful lifetime of 57,000 hours.

In addition to passing the environmental reliability tests described in Sections 5.2

and 6.3, the fan must demonstrate adequate performance after 7,500 on/off

cycles with each cycle specified as 3 minutes on, 2 minutes off, at a temperature

of 70 °C.

See the Fan Specification for 4-wire PWM Controlled Fans for additional details on the

fan specification.

Loading...

Loading...