Case Temperature Reference Metrology

Thermal and Mechanical Design Guidelines 99

18. Place a 3

rd

piece of tape at the end of the step in the groove as shown in

Figure 7-22. This tape will create a solder dam to prevent solder from flowing into

the larger IHS groove section during the melting process.

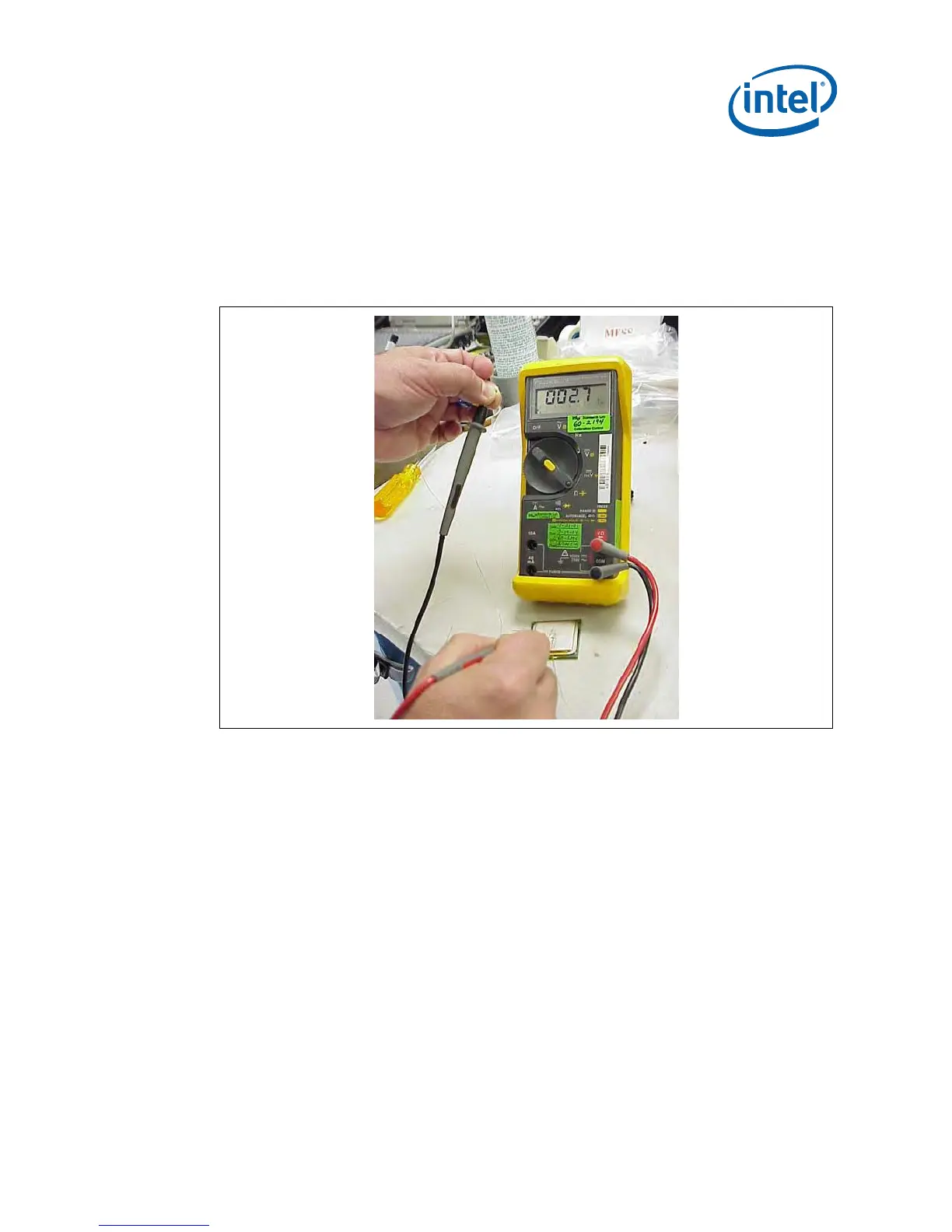

19. Measure resistance from thermocouple end wires (hold both wires to a DMM

probe) to the IHS surface. This should be the same value as measured during the

thermocouple conditioning Section D.5.1.step 3 (Figure 7-23).

Figure 7-23. Measuring Resistance Between Thermocouple and IHS

20. Using a fine point device, place a small amount of flux on the thermocouple bead.

Be careful not to move the thermocouple bead during this step (Figure 7-24).

Ensure the flux remains in the bead area only.

Loading...

Loading...