Maintenance

Maintenance Schedules

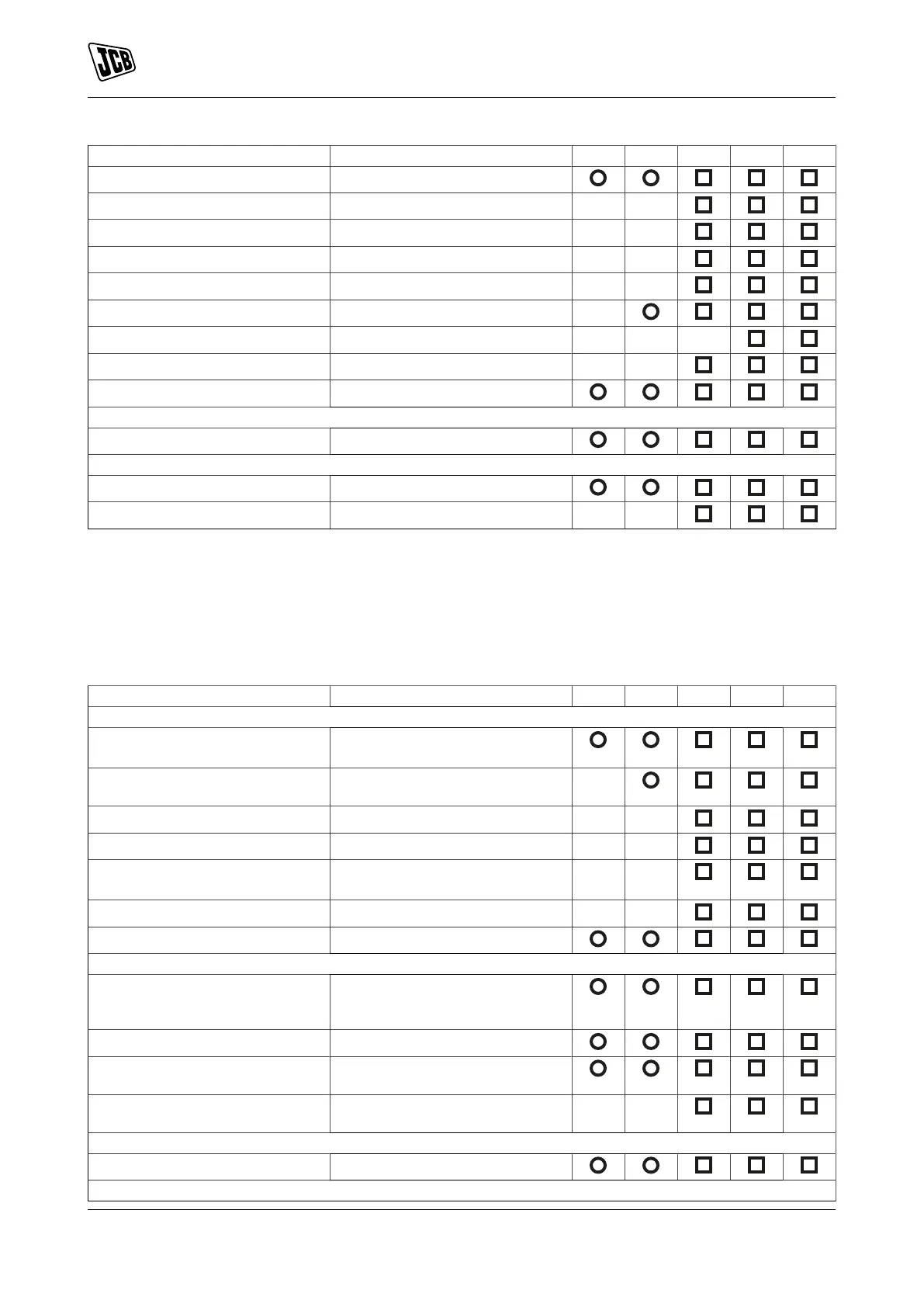

Component Task 10 50 500 1,000 2,000

Dipper Nose to Bucket Lubricate

Bucket Link Lubricate

Tipping lever Lubricate

Kingpost Upper Slew Frame Lubricate

Kingpost Lower Slew Frame Lubricate

Slew Ring Bearing Lubricate

Slew Ring Mounting Bolts Check

Slew Ring Pinion and Gear Teeth Lubricate

Machine Generally Check and Clean

ATTACHMENTS

Quick Hitch Lubricate

OPTIONAL EQUIPMENT

As Required Check

As Required Lubricate

(1) Jobs which should only be done by a specialist.

(2) Clean and lubricate the charge cable end and charging port.

(3) Do a visual check at 500h and re-torque at 1,000h.

(4) To be carried out by authorised/trained technicians only.

Functional Tests and Final Inspection

Table 12.

Component Task 10 50 500 1,000 2,000

Hydraulics

Operation All Services - Excava-

tor, Dozer etc.

(3)

Check (operation)

Hoses and Pipework- Dam-

age/Leaks

Check (operation)

Main Relief Valves Pressure

(1)

Check and Adjust

Auxiliary Relief Valve Pressure

(1)

Check and Adjust

Slew Cross Line Relief Valve

Pressure

(1)

Check and Adjust

Servo relief Valve Pressure

(1)

Check and Adjust

Hydraulic cooler Check/Clean

Electrics

All Electrical Equipment Opera-

tion (e.g. warning lights, beacon,

alarms, horns, wipers etc.

Check (operation)

Hourmeter Check (operation)

Charger Function with JCB

Charge Cable

Check (operation)

Fault codes/Correct level of Soft-

ware (Service Master)

Check (condition)

Undercarriage

Track and running gear Check (operation)

Body and Framework

114 9831/8250-4 114

JCB © Admin Pimteam - 23/06/2021 05:32.