12 - 4

Hydrostatic Pump Endcaps

up to machine no. 751011

Dismantling and Assembly

The numerical sequence shown on the illustration is

intended as a guide to dismantling.

For assembly the sequence should be reversed.

Each endcap 8, 9 is secured to its pump by four capscrews

2. Before dismantling, matchmark each endcap to its pump.

Note that 'O' rings 4 and 5 are only fitted to the rear pump

endcap 8. Locating dowels 6 need only be removed if

damaged.

Note that shims 15 should be retained as a set. On

reassembly, use new 'O' rings and bearings.

Torque tighten bolts 2 to 47 - 61 Nm (4.8 - 6.2 kgf m, 35 - 45

lbf ft).

Torque tighten plug 14 to 54 - 135 Nm (40 - 100 lbf ft, 5.5 -

14 kgf m).

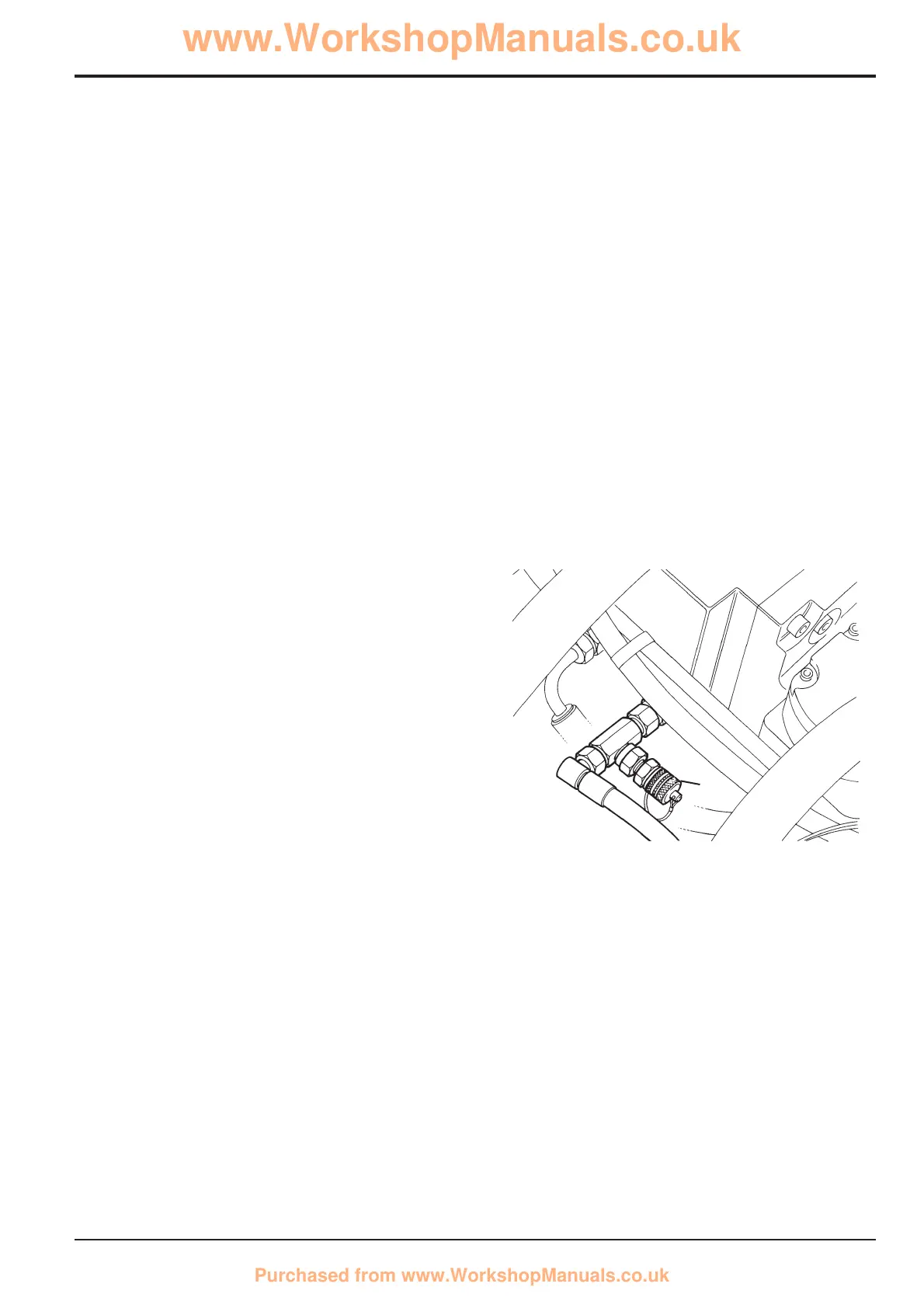

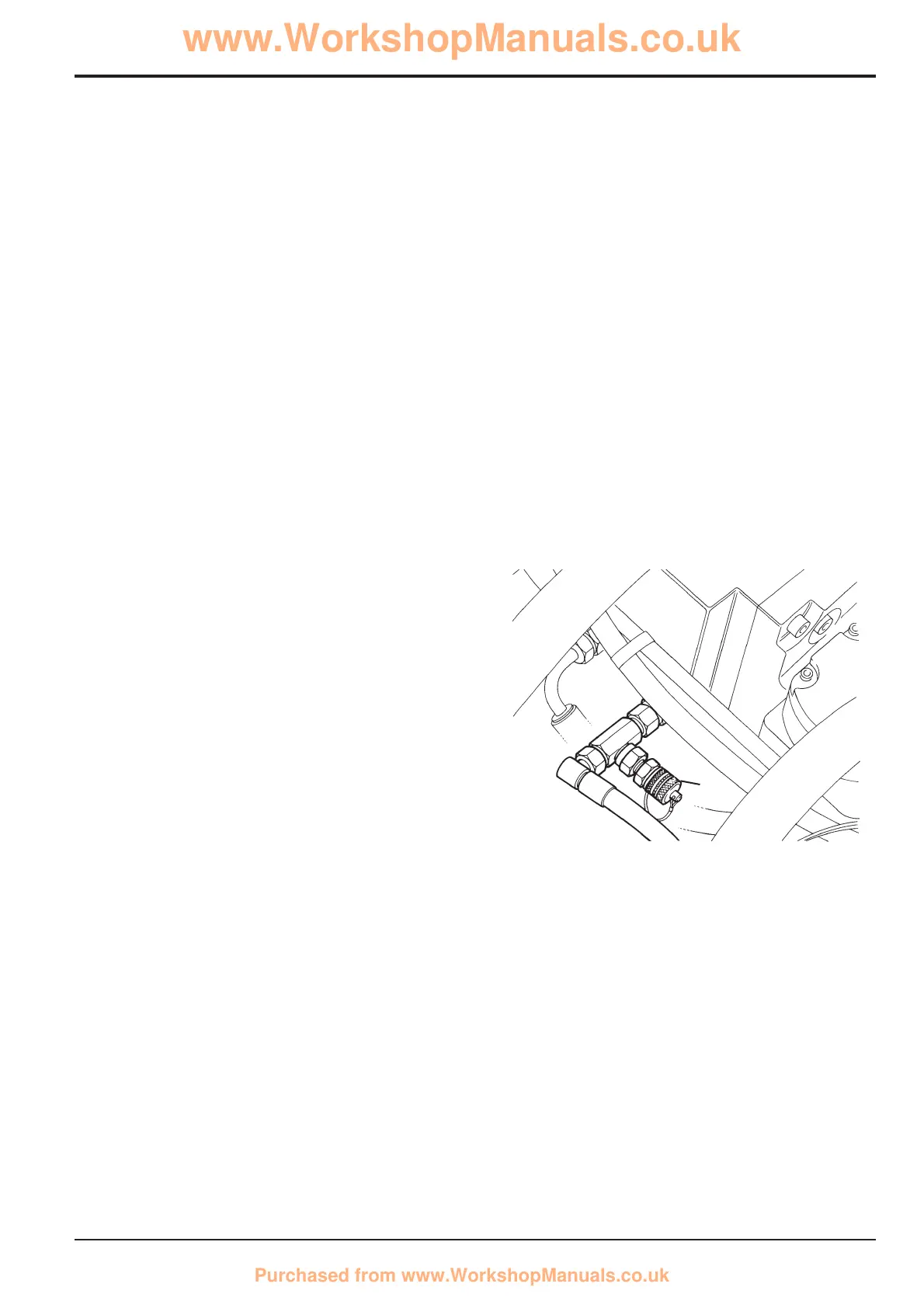

Charge Pressure Checking and Adjustment

1 Stop engine. Connect a 0 - 40 bar (0 - 600 lb/in

2

, 0 - 42

kg/cm

2

) pressure gauge into test point X situated

underneath the pump.

2 Start engine and check pressure is as specified in

Technical Data.

3 If the pressure is not as specified, stop the engine.

Unscrew locknut 13 and turn adjuster 12 4 turn at a

time (clockwise to increase pressure) then re-tighten

locknut. Start engine and re-check pressure. Continue

procedure until pressure is correct then remove

pressure gauge.

Section E Hydraulics

9803/8550

Section E

12 - 4

Issue 4*

Pumps

*

S246240

X

Loading...

Loading...