− 38 −

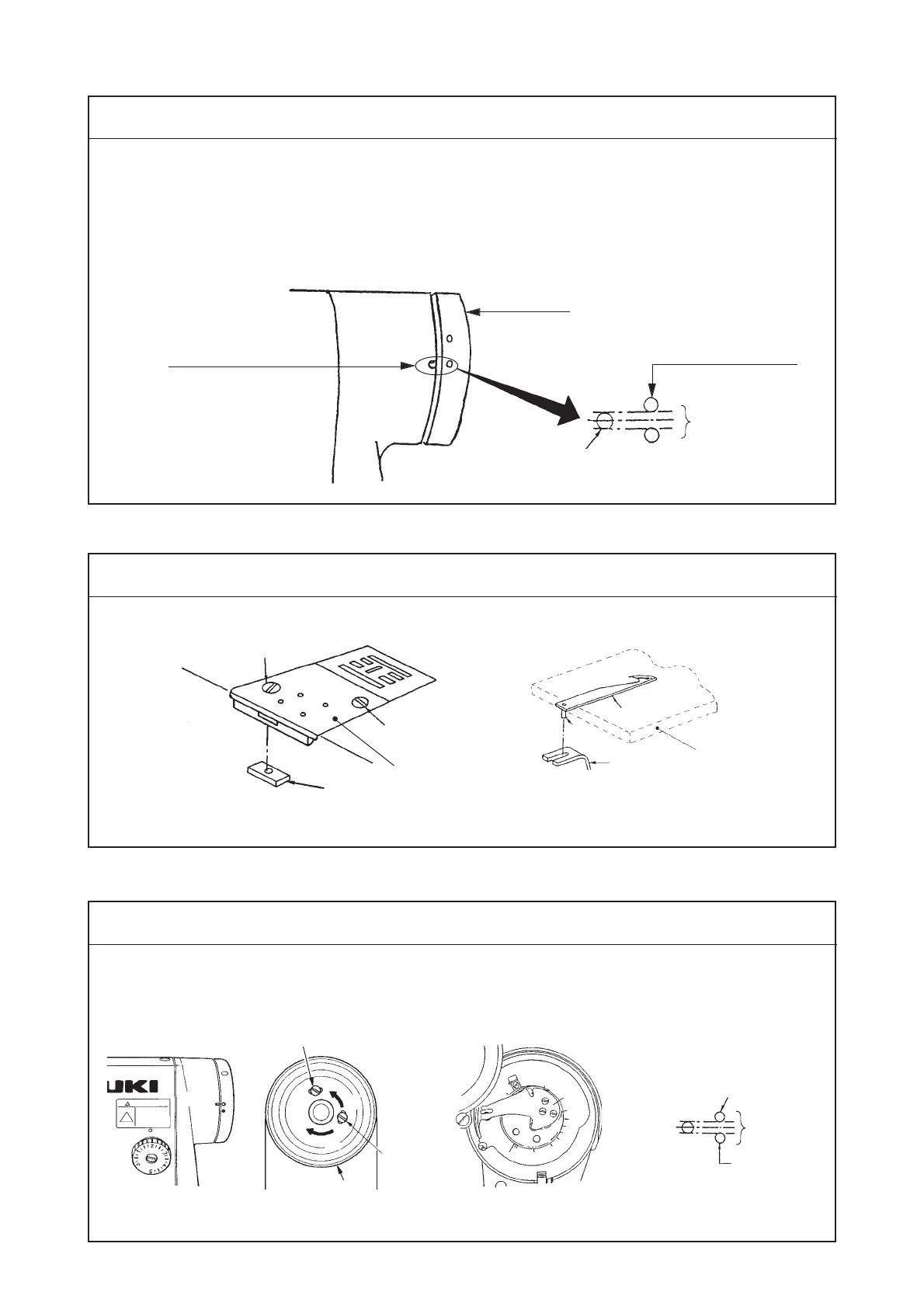

(25) Timing of the thread trimming cam(Thread trimmer type only)

Standard Adjustment

(See the figure shown above.)

™ Press roller arm 6 until roller 4 fits in the groove in thread trimming cam 8. Now, lightly turn the

main shaft handwheel carefully in the reverse direction until it stops. At this time, the marker dot

engraved on the machine arm should be aligned with the red marker dot engraved on the handwheel.

Adjust the thread trimming cam longitudinally within the width of a dot.

Machine arm

Width of

adjustment

Red engraved marker

dot on handwheel

Engraved marker dot on

machine arm

Handwheel

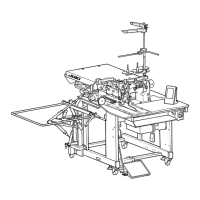

(26) Installing/removing the knife unit (Thread trimmer type only)

Standard Adjustment

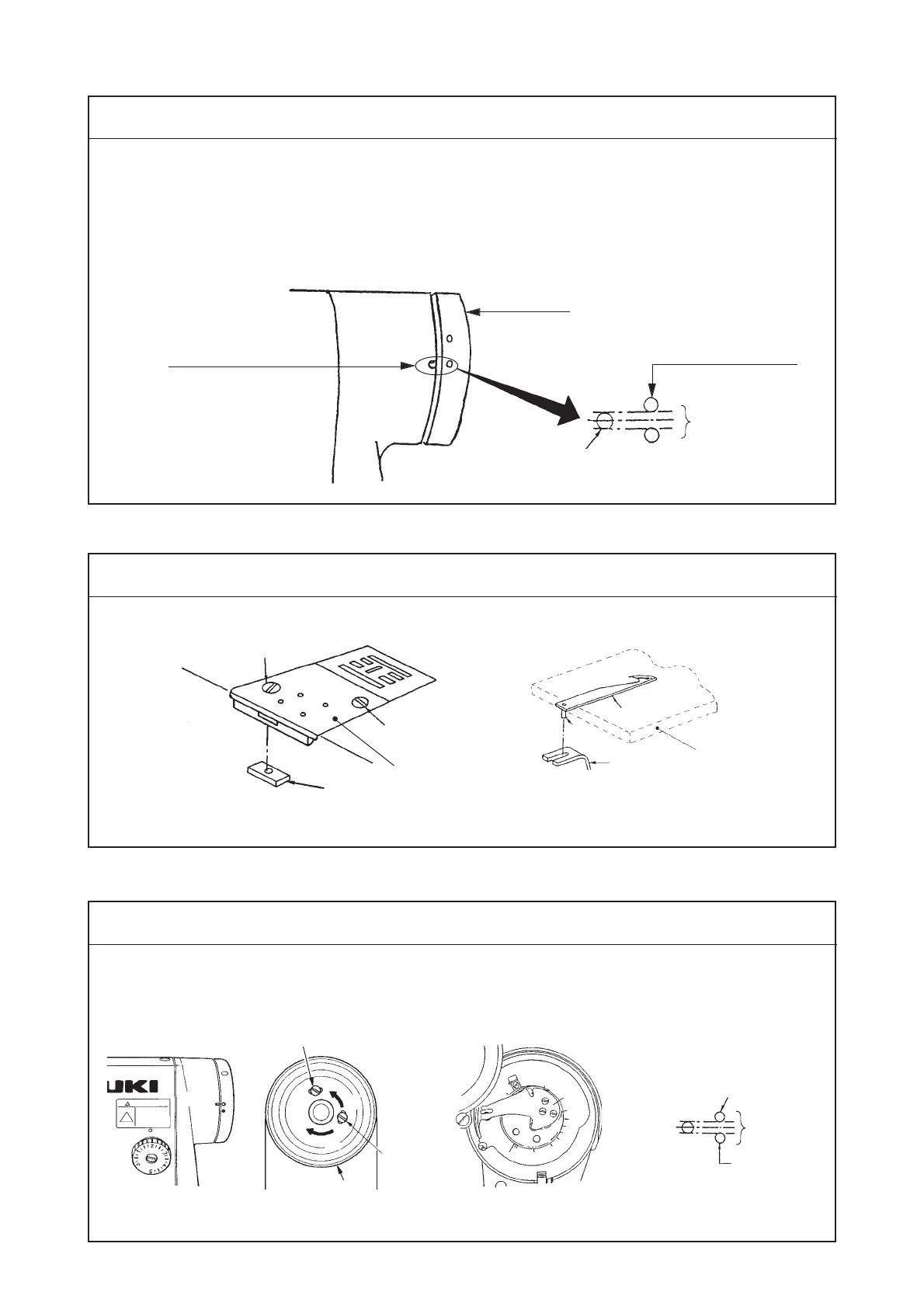

(27) Stop position of the needle after thread trimming (Needle UP stop)

Standard Adjustment

1

™ The standard stop position of the needle (position at which the marker dot engraved on the machine

arm is aligned with the white marker dot engraved on the handwheel) is when the marker line

engraved on the thread take-up is aligned with the marker line engraved on the face plate (60˚).

™ Adjusting range is within one engraued marker dot in front and rear.

Handwheel

Machine

arm

(Advances)

(Retards)

Adjusting

range

Handwheel

A

B

1

2

3

2

6

5

4

Knife unit

Knife unit

A:

Needle UP stop

B: Needle DOWN stop

D

H

F

C

G

A

B

E

J

I

Loading...

Loading...