− 78 −

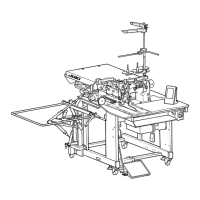

(3) Maintenance of the hook lubricating pipe oil filter

It is recommended to periodically clean the inside of the filter of the hook lubricating pipe oil filter.

Remove pipe stop ring (large) 1 and remove thread waste or the like collected to wire netting section 2.

* Be careful of the damage of the lubricating pipe or the like at the time of maintenance of the filter.

Hook lubricating

oil filter

2

1

1

(Procedure 2) Replacement from the front cover (long-sized Phillips screwdriver is necessary,)

1) Oen the rear cover.

2) Remove two green/yellow cords attached to PWR printed circuit board from the screw of earth mecca at

the bottom of the box.

3) Draw out connector cords of CN11, CN25, CN23, CN13, CN22, CN21, CN12, CN24, CN29, and CN38

on PWR printed circuit board.

4) Draw out connector cord of CN44 on CTL printed circuit board.

5) Tilt the sewing machine and remove six screws in the front cover from the gap of the under cover or the

like. (When loosening the screws, be careful that the front cover does not fall since there is no catch.)

6) Remove 9 screws on PWR circuit board from the front cover removed.

7) Assemble by reversing the above removing order.

3. BTPM circuit board

1) Draw out all connector cords inserted on BTPM circuit board.

2) Remove four screws on BTPM circuit board.

3) Assemble by reversing the above removing order.

4. CTL circuit board

1) Draw out all connector cords inserted on BTPM circuit board and CTL circuit board.

2) Remove the catch and remove CTL circuit board together with the rear cover from the control box main

unit.

3) Remove four screws and remove BTPM circuit board together with the metal plate,

4) Remove 7 screws on CTL circuit board.

5) Assemble by reversing the above removing order.

Loading...

Loading...