– 27 –

❸

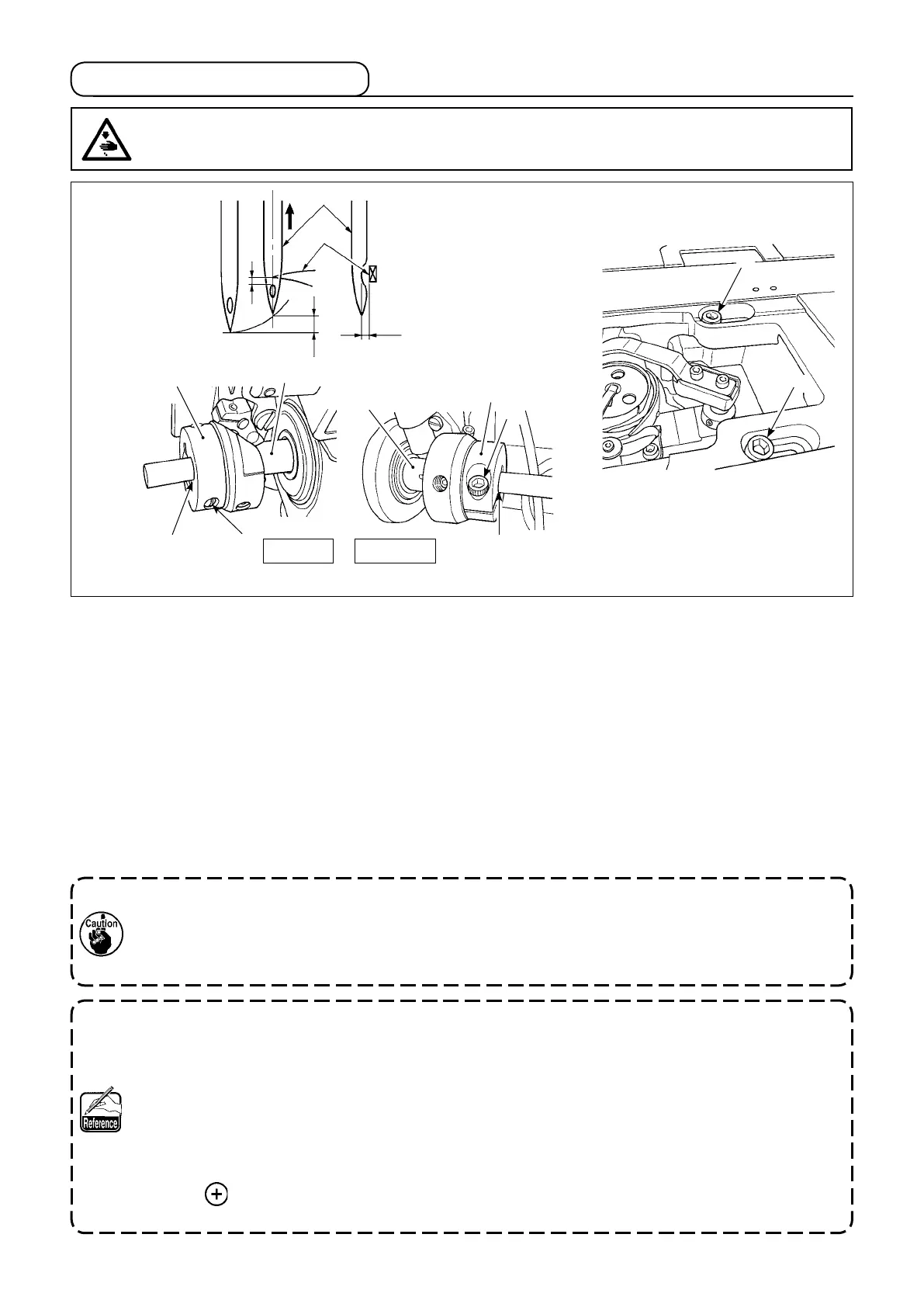

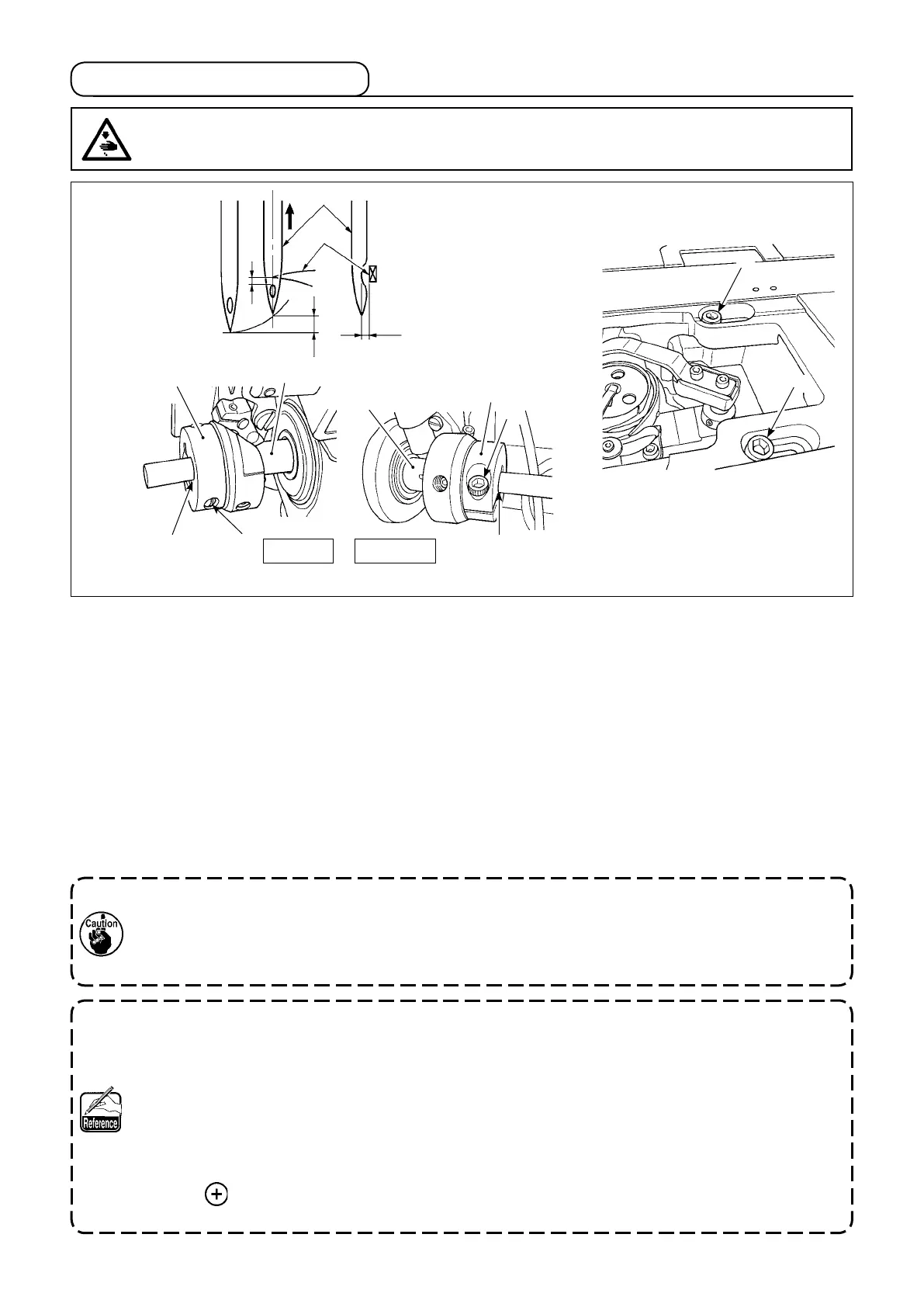

1) Adjust the standard feed adjusting dial to "0".

(Caution 1)

2) Loosen hook driving shaft set collar clamping screw

❸

, and turn the handwheel counterclockwise to

make the needle bar ascend by 2.3 mm from the lowest position of its stroke.

3) In the state described in 2), align blade point

❶

of the hook with the center of needle

❷

, and tighten

hook driving shaft set collar clamping screw

❸

. At this time, a clearance of 1.5 mm is provided be-

tween the blade point of the hook and the top end of the needle eyelet. (The hook driving shaft set collar

should be ush with end faces C and D of the hook driving shaft.)

4) Loosen setscrews

❹

and

❺

of the hook driving shaft saddle on the top face of the bed. Adjust the clear-

ance between the blade point of the hook and the needle to 0.05 to 0.1 mm by moving the hook driving

shaft saddle to the right or left to change its position. Then, tighten setscrews

❹

and

❺

.

5) Align the largest scale mark of the standard feed adjusting dial with the marker dot on the machine arm.

Check to be sure that the blade point of the hook does not come in contact with the needle.

1. If stitch skipping and thread breakage occur when using elastic thread such as vinylon, adjust the

hook timing with the pitch used for sewing.

2. The operation panel could come in contact with the thread stand when tilting the machine head.

To protect the relevant parts from contact, shift the thread stand to a position at which the thread

stand does not interfere with the control panel.

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

[Only for the LU-2810-7, LU-2860-7, LU-2818-7 and LU-2868-7]

To check the needle bar position as described in the aforementioned 2) [i.e., "...the needle bar ascend

by 2.3 mm from the lowest position of its stroke"], you may use the display of the main shaft rotation

angel under the "machine head adjustment mode" of the SC-922.

Increase the numerical value displayed when the needle bar is in its lowest position of its stroke under

the "machine head adjustment mode" by 25 degrees of an angle, the needle bar goes up by 2.3 mm.

(When the needle bar ascends by 2.3 mm from its lowest position of its stroke, the main shaft rotation

angle is 25 degrees of an angle.)

* In the case of adjusting the needle-to-hook relation under the "machine head adjustment mode", do

not press switch. Refer to "II-10. Adjustment of the machine head" in the Instruction Manual for

the SC-922 for the machine head adjustment mode.

4-5. Needle-to-hook relation

0.05 to 0.1 mm

❷

❶

1.5 mm

2.3 mm

❹

❺

❸

Hook driving shaft

setting collar

The hook driving shaft setting

collar is aligned with the end

face of hook driving shaft C

Right hook

Hook driving shaft D

Hook driving shaft

setting collar

The hook driving shaft

setting collar is aligned

with the end face of hook driving shaft D

Hook driving shaft C

Left hook

Loading...

Loading...