– 46 –

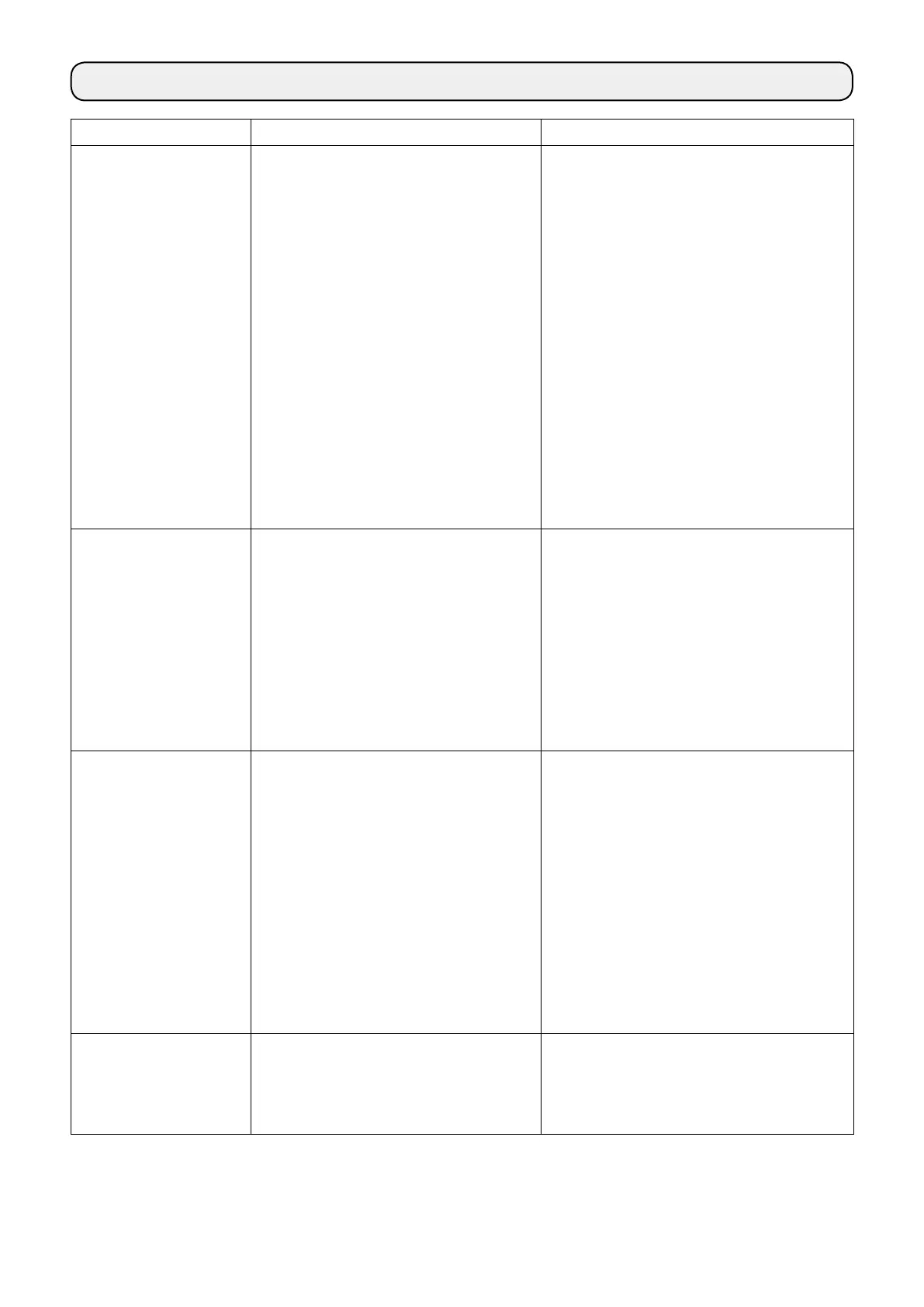

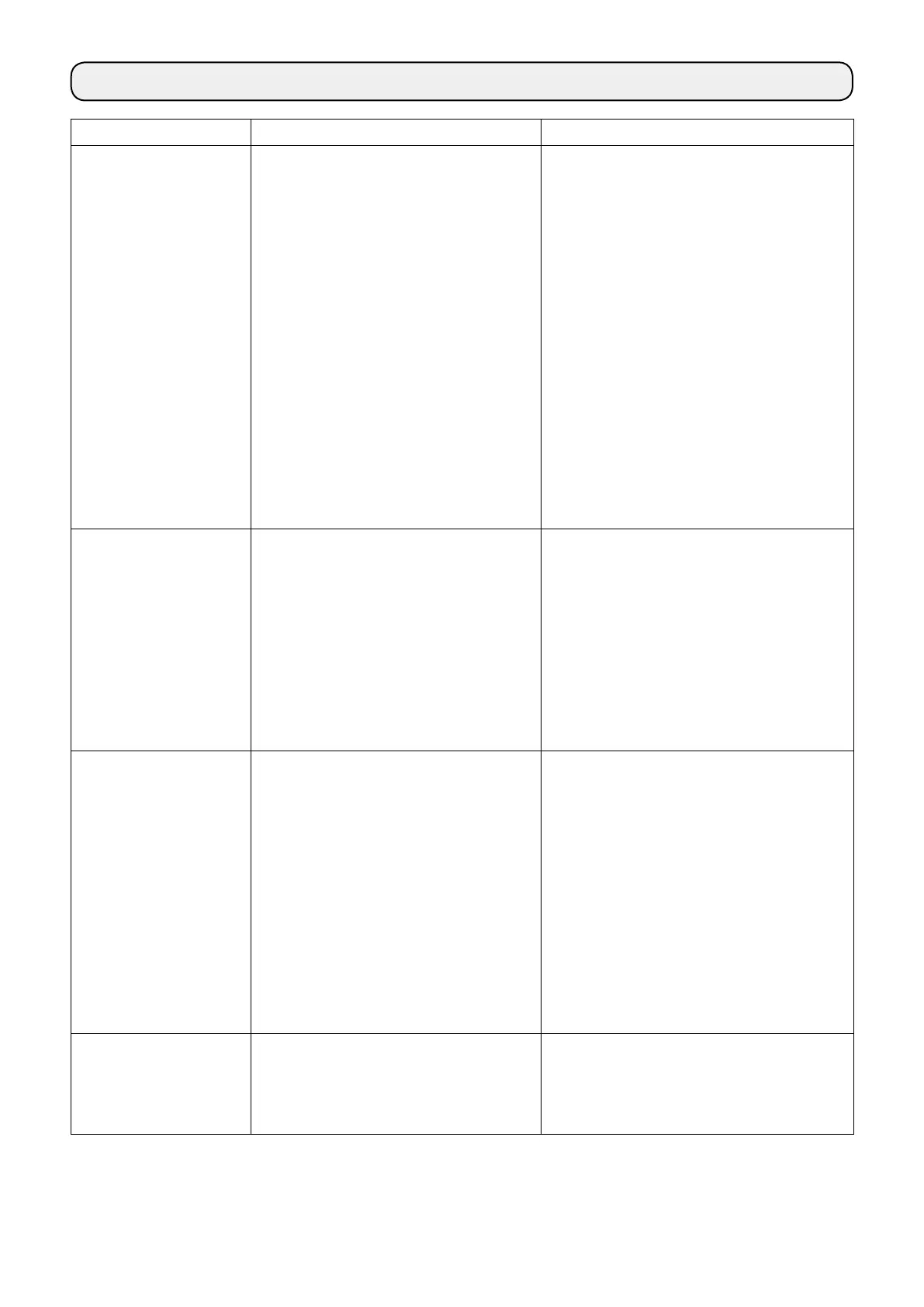

8. TROUBLES IN SEWING AND CORRECTIVE MEASURES

Troubles Causes Corrective measures

1. Thread breakage

(Thread frays or is

worn out.)

(Needle thread trails 2

to 3 cm from the wrong

side of the fabric.)

①

Thread path, needle point, hook blade

point or bobbin case resting groove on

the throat plate has sharp edges or burrs.

②

Needle thread tension is too high.

③

Bobbin case opening lever provides an

excessive clearance at the bobbin case.

④

Needle comes in contact with the blade

point of hook.

⑤

Amount of oil in the hook is too small.

⑥

Needle thread tension is too low.

⑦

Thread take-up spring works excessively

or the stroke of the spring is too small.

⑧

Timing between the needle and the hook

is excessively advanced or retarded.

○

Remove the sharp edges or burrs on the

blade point of hook using a ne emery paper.

Buff up the bobbin case resting groove on

the throat plate.

○

Decrease the needle thread tension.

○

Decrease the clearance provided between

the bobbin case opening lever and the

bobbin. Refer to

"4-7. Adjusting the bobbin

case opening lever" p.29

.

○

Refer to

"4-5. Needle-to-hook relation"

p.27

.

○

Adjust the amount of oil in the hook properly.

Refer to

"3-1. Lubrication" p.12

.

○

Increase the needle thread tension.

○

Decrease the tension of the spring and

increase the stroke of the spring.

○

Refer to

"4-5. Needle-to-hook relation"

p.27

.

2. Stitch skipping

①

Timing between the needle and the hook

is excessively advanced or retarded.

②

Pressure of the presser foot is too low.

③

The clearance provided between the top

end of the needle eyelet and the blade

point of hook is not correct.

④

Hook needle guard is not functional.

⑤

Improper type of needle is used.

○

Refer to

"4-5. Needle-to-hook relation"

p.27

.

○

Tighten the presser spring regulator.

○

Refer to

"4-5. Needle-to-hook relation"

p.27

.

○

Refer to

"4-6. Adjusting the hook needle

guard" p.28

.

○

Replace the needle with one which is thicker

than the current needle by one count.

3. Loose stitches

①

Bobbin thread does not pass through the

tension spring of the inner hook.

②

The hook, feed dog or the thread path

of thread guide, etc. has worn out or has

aws.

③

Bobbin fails to move smoothly.

④

Bobbin case opening lever provides too

much clearance at the bobbin.

⑤

Bobbin thread tension is too low.

⑥

Bobbin has been wound too tightly.

⑦

The needle does not match the needle

hole in the feed dog.

○

Thread the bobbin thread correctly.

○

Remove rough parts with a ne emery paper

or buff it up.

○

Replace the bobbin or hook with a new one.

○

Refer to

"4-7. Adjusting the bobbin case

opening lever" p.29

.

○

Increase the bobbin thread tension.

○

Decrease the tension applied to the bobbin

winder.

○

Change the feed dog appropriately. (Refer to

the Parts List.)

4. Thread slips off

the needle eyelet

simultaneously with

thread trimming.

①

Thread tension given by the tension

controller No. 1 is too high.

○

Decrease the thread tension given by the

tension controller No. 1.

Loading...

Loading...