– 109 –

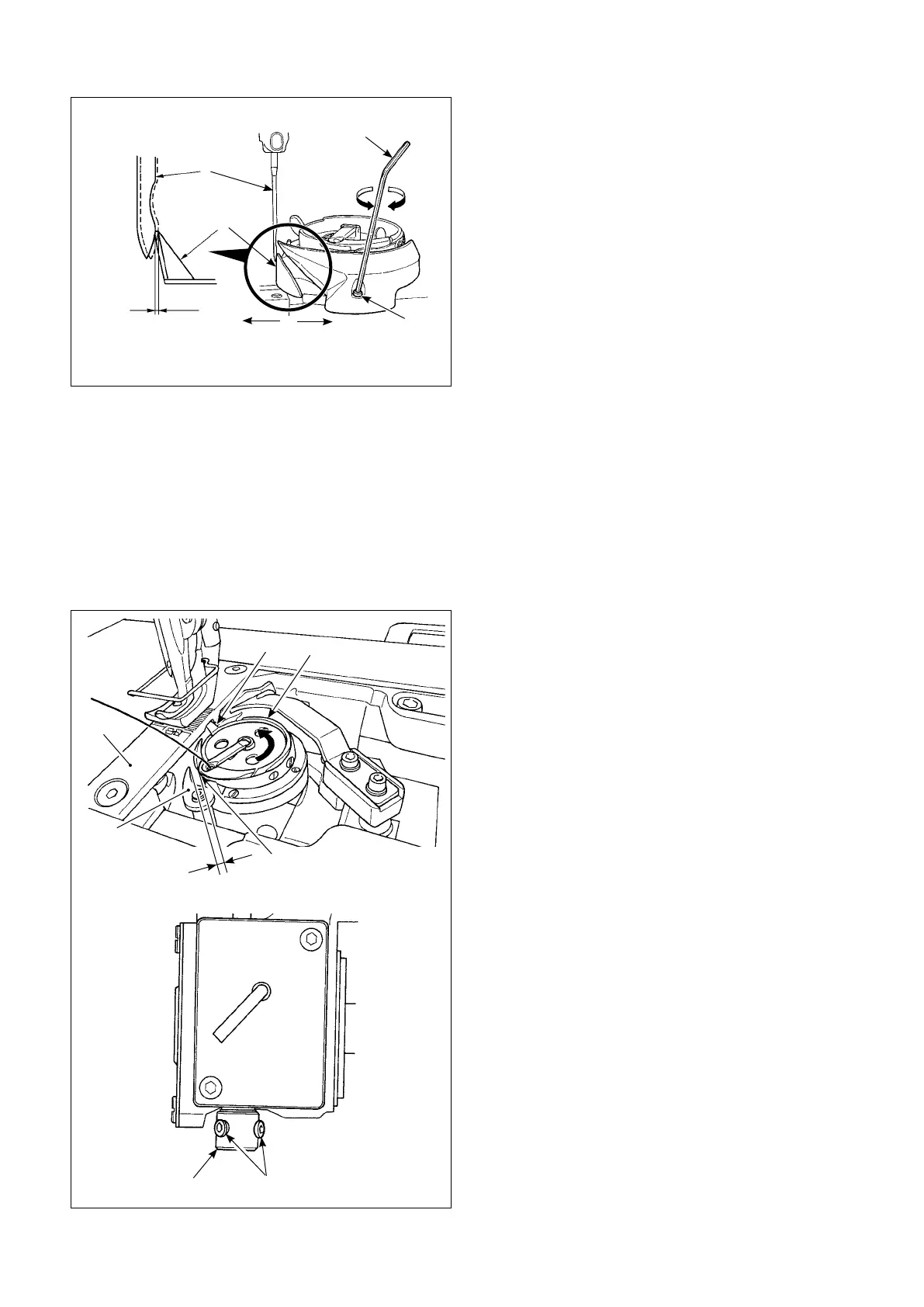

When a hook has been replaced, be sure to check

the position of the hook needle guard.

As the standard position of the hook needle guard,

hook needle guard

must push the side face of

needle

to lean the needle by 0.05 to 0.2 mm away

from its straight position.

If the state of the hook is not as shown above, fit

hexagon wrench

into

of needle guard adjusting

screw and adjust as follows:

1) Place the sewing machine into the hook adjust-

ment mode.

2) To bend the hook needle guard in direction

a

, turn

the needle guard adjusting screw in direction

A

.

3) To bend the hook needle guard in direction

b

, turn

the needle guard adjusting screw in direction

B

.

4) At the nal step of procedure, appropriately adjust

the clearance provided between the needle and

the hook.

0.05 to

0.2 mm

B

A

a

b

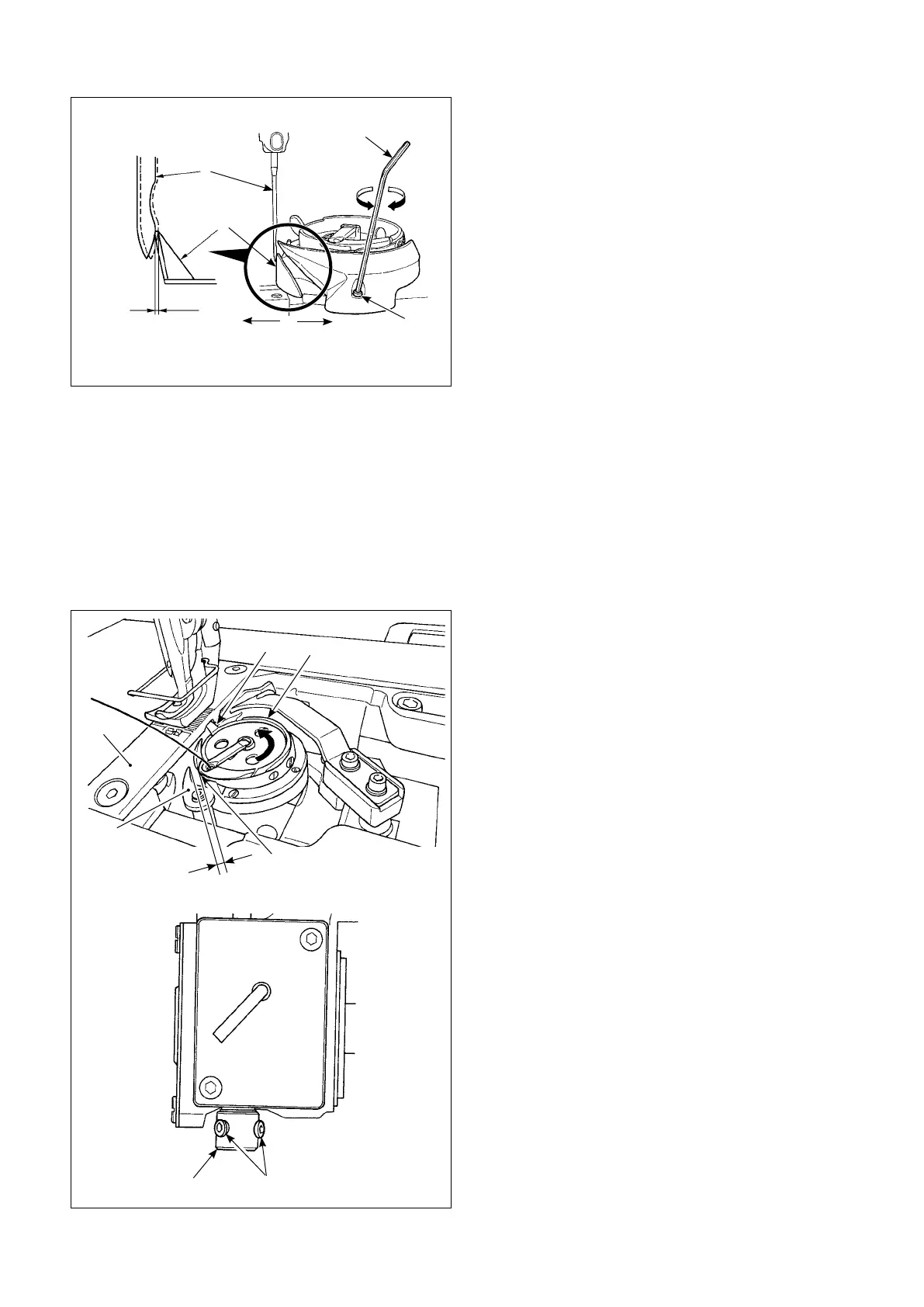

1) Place the sewing machine into the hook adjust-

ment mode.

2) Turn the handwheel in its normal rotational di-

rection to bring bobbin case opening lever

to

its back end position.

3) Turn inner hook

in the direction of the arrow

until stopper

is pressed against the slits in

throat plate

.

4) Loosen setscrews

of the bobbin case open-

ing lever sleeve. Adjust the clearance provided

between the bobbin case opening lever and

the projection

A

of the bobbin case to 0.9 to 1.1

mm. Tighten setscrews

while pressing bobbin

case opening lever

downward and pressing

the bobbin case holding lever sleeve

upward.

8-3. Adjusting the hook needle guard

8-4. Adjusting the bobbin case opening lever

A

0.9 to 1.1 mm

Loading...

Loading...