– 28 –

Switch "off" the motor.

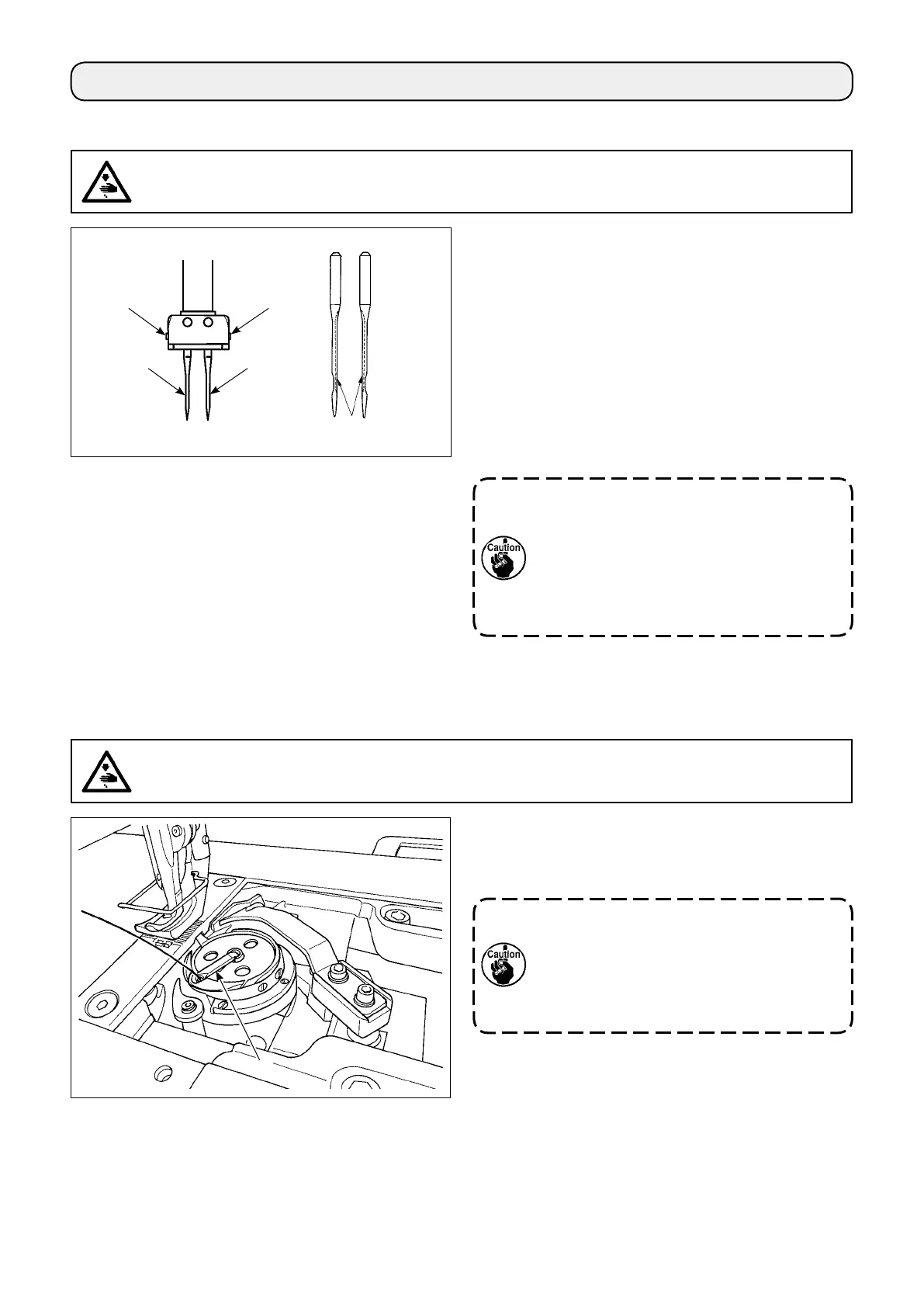

Use 134-35 needles.

1) Turn the handwheel to bring the needle bar to

the highest position of its stroke.

2) Loosen needle clamp screws

. Hold needles

so that long grooves in them are respectively

faced inside.

3) Push needle

deep into the needle clamp hole

until it will go no further.

4) Tighten needle clamp screw

rmly.

Long groove

When replacing the needle, check the clear-

ance provided between the needle and the

blade point of hook. (Refer to "8-1. Needle-

to-hook relation" p.107 and "8-3. Adjusting

the hook needle guard" p.109.)

If there is no clearance, the needle and the

hook will be damaged.

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

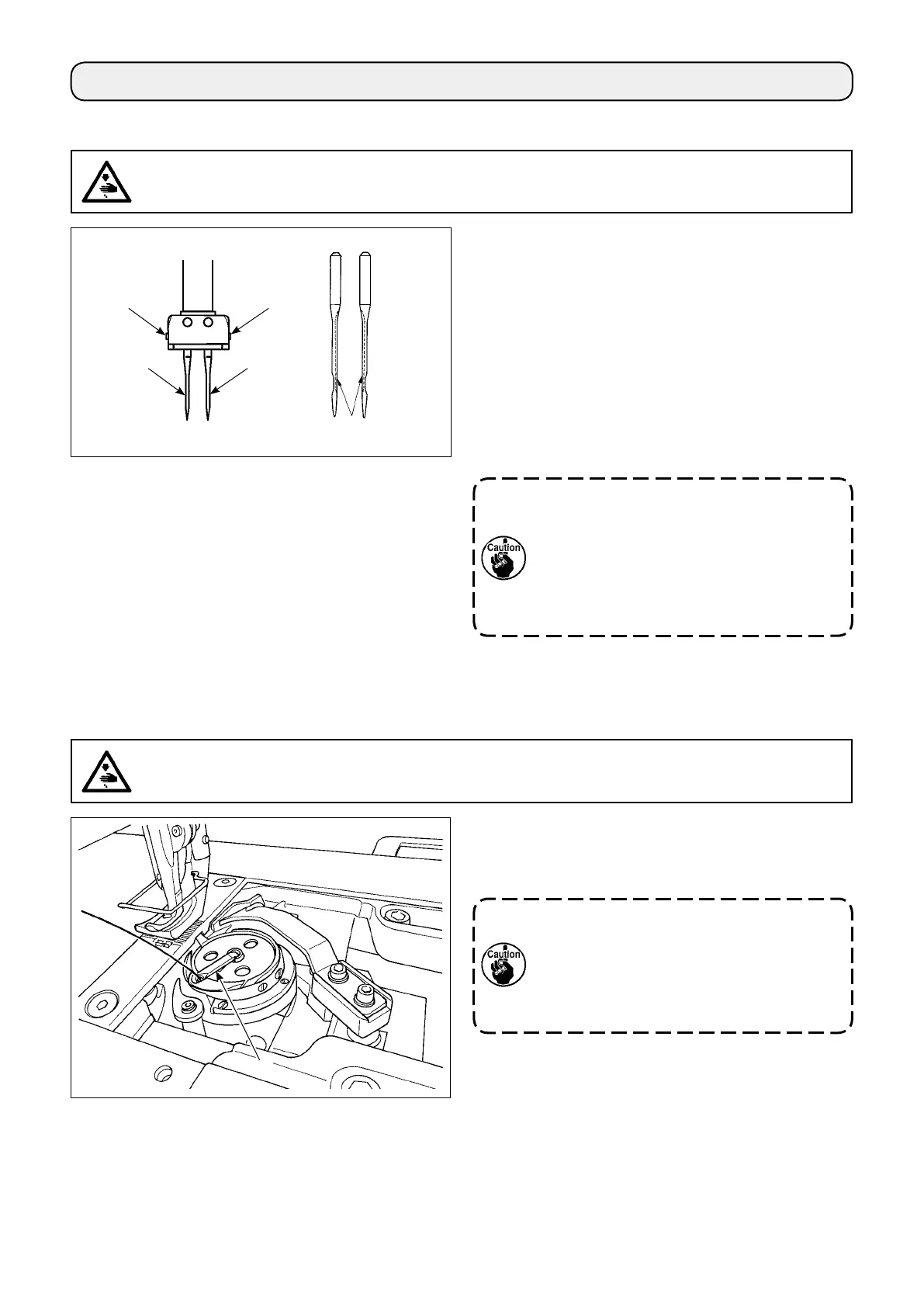

1) Lift latch

of hook, and take out the bobbin.

2) Put the bobbin into the shaft in the hook correct-

ly and release the latch

.

1. Do not make the machine run idle with

the bobbin (bobbin thread). The bobbin

thread is caught in the hook. As a result,

the hook may be damaged.

2. Be careful so as not to get hurt with the

top end of the counter knife.

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

3-1. Attaching the needle

3-2. Attaching and removing the bobbin

3. PREPARATION BEFORE SEWING

Loading...

Loading...