2-39

Adjustment Item

Linearity

PB Switching

Error Rate

Adjustment

Point Adjustment

Adjustmenmt

Service Point

2.13

COMPATIBILITY AND ERROR RATE ADJUSTMENTS

2.13.1 Preparation

Before disassembly and adjustment, back up the data stored

in the EEPROM (IC1504 on the DV MAIN board) using the

Service Support System Software (SSS software).

Table 2-18-1 shows the important service points for the com-

patibility and error rate adjustments.

Drum replacement Required Required Required

Note 1

Transport part Required Not Check

replacement Note 1

Transport part Required Not Check

(drum) repair Note 1

IC4001

(PRE/REC amp on Not Not Check

DV MAIN board)

replacement

IC2001

(PB. EQ on DV Not Not Required

MAIN board)

replacement

DV MAIN board

replacement Not Required Required

Note 2

Note 1 :

• The linearity adjustment is required only after servicing or

replacing the drum or the take up/supply guide rail.

Note 2 :

•

After replacing the DV MAIN board, write the original data in

the EEPROM of the new board. If write communication is not

possible, mount the original EEPROM on the new board.

When adjustments of more than one item are required, use

the following order for the adjustments.

2.13.2 Adjustment

The actual adjustment requires the following preparation.

1. Tools required for adjustment

Alignment tape

US : MC-1

PAL : MC-2

SSS software

PTU94016-4

Guide driver

YTU94085

Jig connector cable

PTU94018B

PC cable

US : QAM0099-002

PAL : QAM0099-005

Jig RCU

PTU94023B

2. Procedure

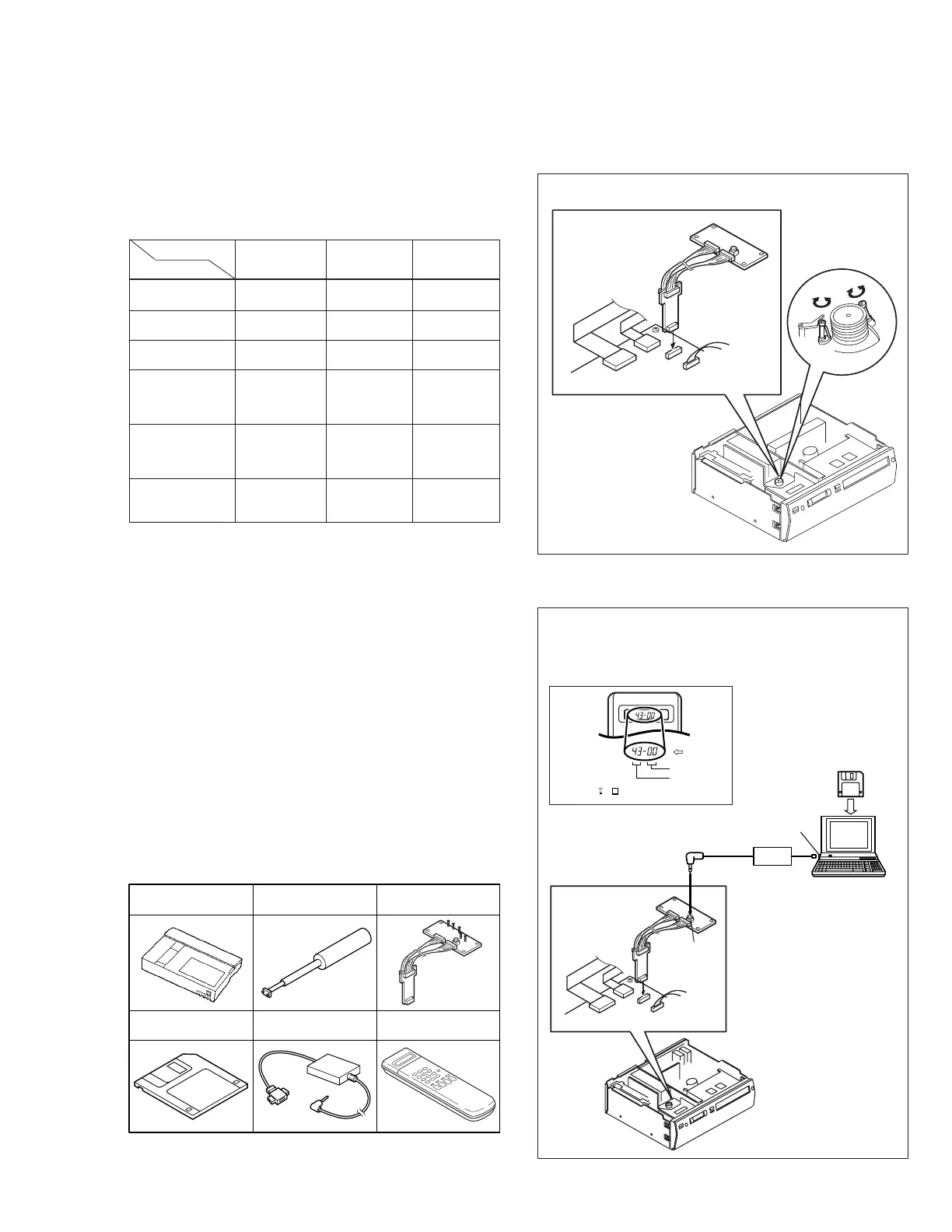

1. Take out the 6 screws, then remove the top cover. (See

Fig. COM1 on page 1-2 of section 1.4.)

2. Connect the jig connector cable to CN2001 on the DV

MAIN board.

Fig. 2-13-2

DV MAIN PWB

Jig Connector Cable

PTU94018B

CN2001

CN1501

CN1503

CN3701

Table 2-13-1

2.18.3 Linearity Adjustment

∫

2.18.4 PB Switching Point Adjustment

∫

2.18.5 Error Rate Adjustment

Fig. 2-13-1

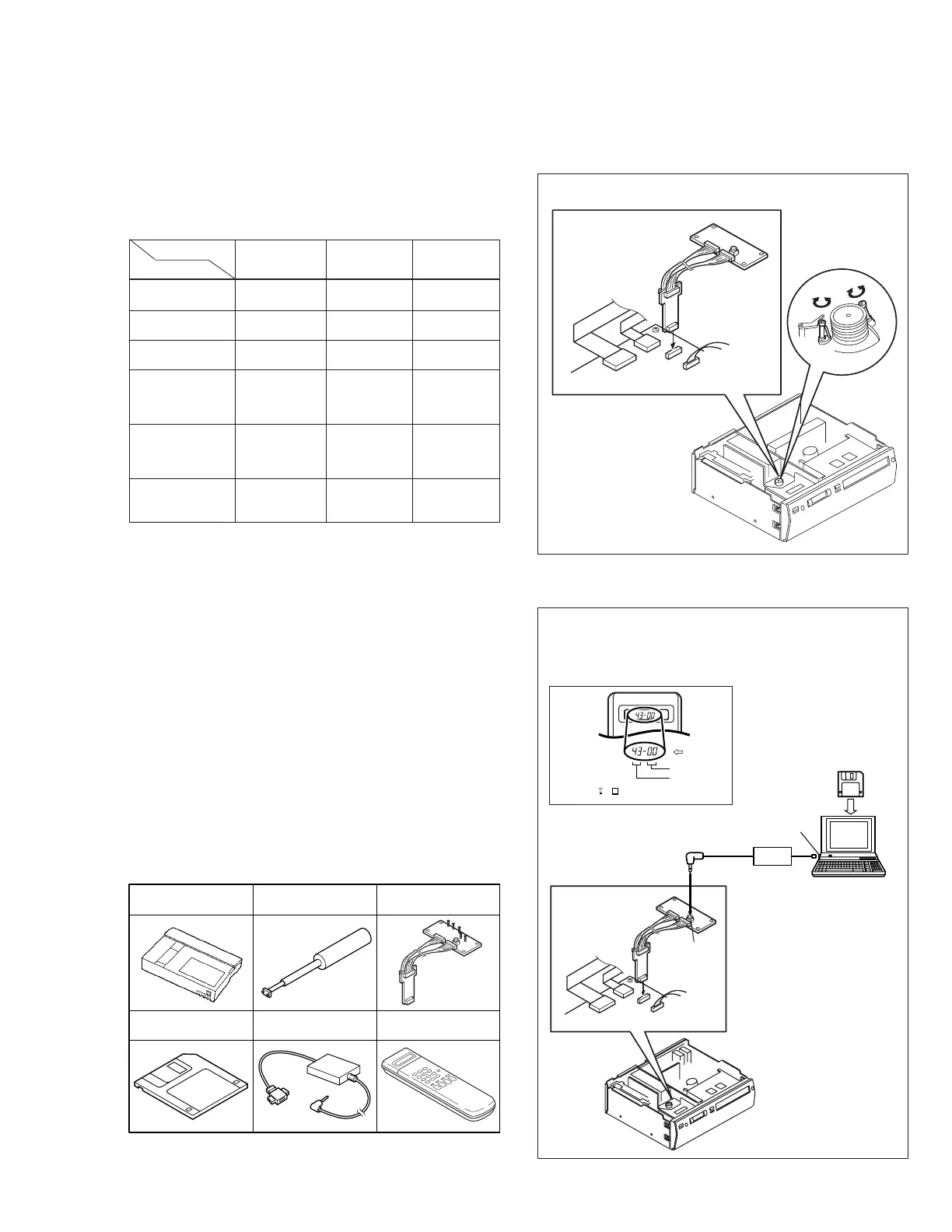

Fig. 2-13-3

Service Support Software

RS-232C Port

PC Cable

Personal Computer

JVC

MENU

INITIAL MODE

DATA CODE

CUSTOM CODE

43: A CODE

[Data transmitting method]

Depress the “ ” ( 3 ) button

after the data code is set.

Jig RCU

[PTU94023B]

DV MAIN PWB

CN2001

CN1501

CN1503

CN3701

<JLIP>

– Setup by extending the jig connector –

When performing the adjustment by the SSS software, set the VCR

to JIG mode by transmitting the code "menu", "2", "8", and "OK" in

order from the Jig RCU, and set the VCR to external communication

mode by transmitting the code "8C" from the Jig RCU.

3. Setup for computer adjustment

Loading...

Loading...