H .

..

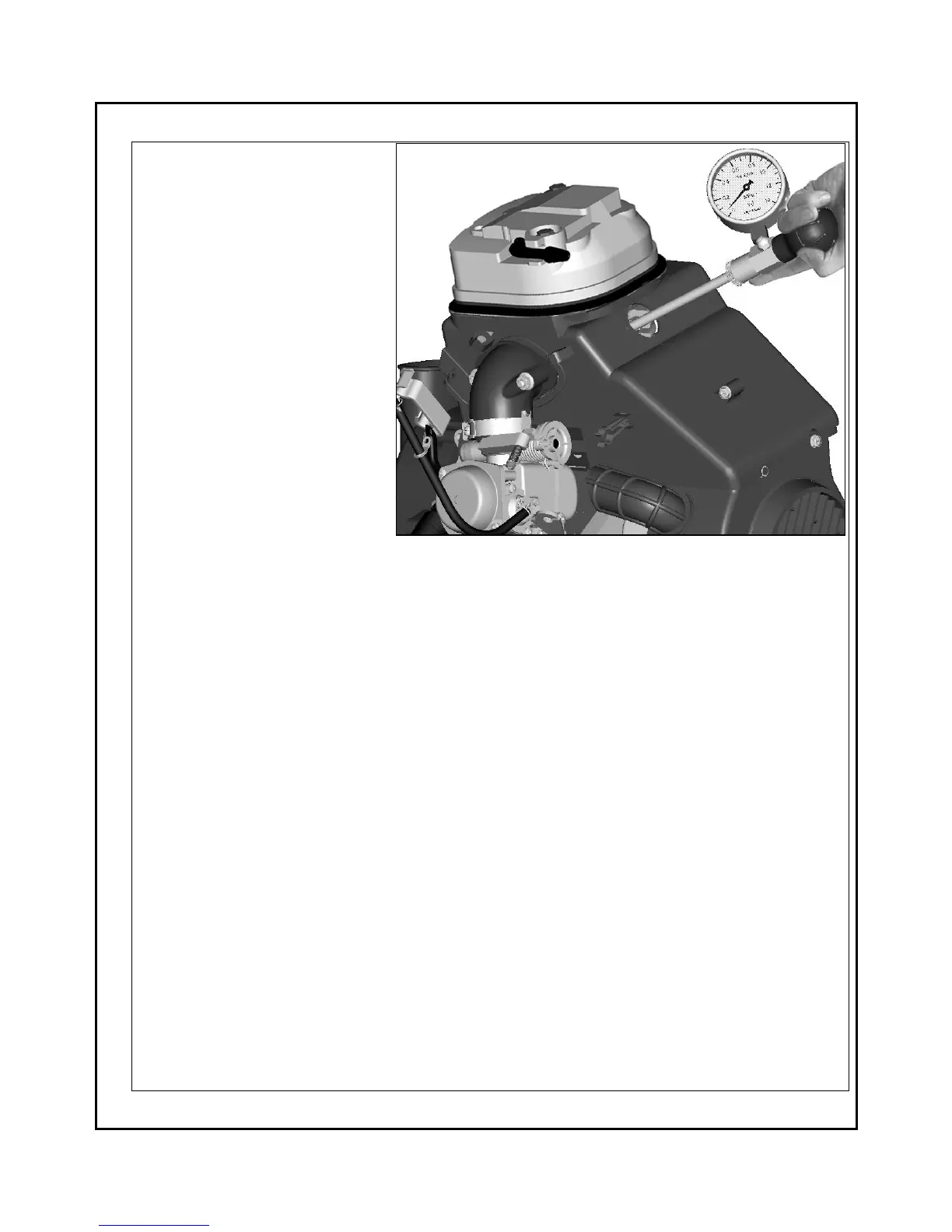

. M E A S U R E A I R P R E S S U R E I N C Y L I N D E R

STEP ONE:

::

:

1. Start engine until temperature reaches

its requirement.;

2. Remove spark plug and join pressure

gauge.;

3. Inspect the following switchs:

(a) Fuel switch is in “OFF”

position.;

(b) Ignition switch is in “OFF”

position;

4. Play up throttle completely,

start engine for several times

(6-8 times));

5. Note reading, and do the

6. above steps three times and calculate

their average value as actual

compression pressure, which should

be 11±1Kg/cm

2

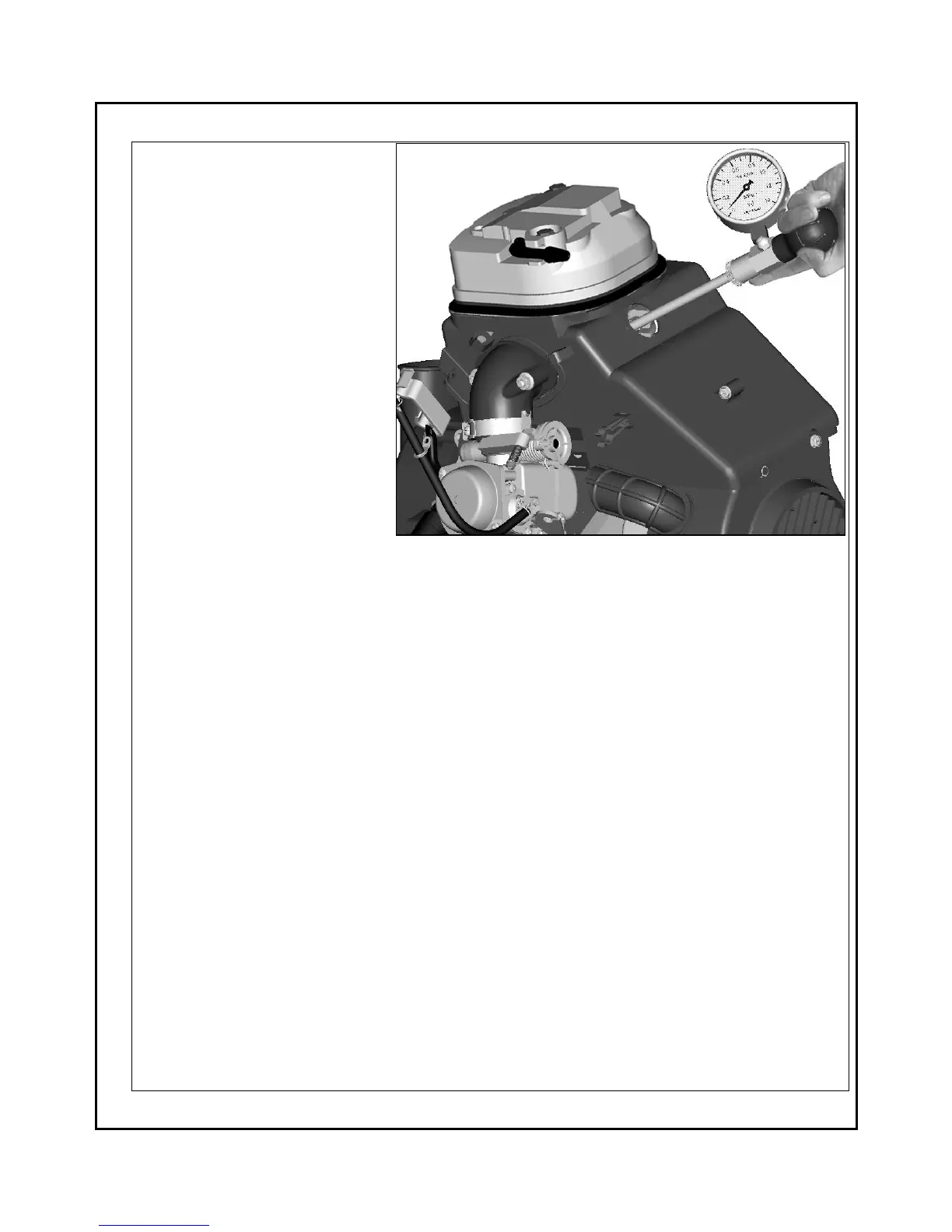

STEP 2:

::

:

When air pressure in cylinder is below 12Kg/cm

2,

,install spark plug, restart and warm up engine,

remove spark plug and drop several drops of oil in combustion chamber, messure it againe following step

ONE with manometer;

● If the pressure in cylinder adds, inspect:

a. If cylinder is abraded;

b. If piston/ring is abraded;

c. If there is scratch or block for cylinder/piston;

d. If piston is blocked completely in piston groove.

●if the pressure in cylinder doesnot increase, inspect:

a. If valve clearance is correct;

b. If cylinder head scres is fastened too tight or loosened;

c. If valve holder is abraded;

d. If valve is curved;

e. If valve timing is correct;

f. If cylinder head gasket is abraded.

STEP 3:

::

:

When the pressure in cylinder is over 12Kg/cm

2

,clear deposited carbon in cylinder head, pistion, combustion

chamber, at the same time inspect exhaust port.

Loading...

Loading...