specifi c area of piston. Detonation generally occurs from

using low octane fuels.

Preignition or ignition of fuel charge before timed spark

can cause damage similar to detonation. Preignition

damage is often more severe than detonation damage.

Preignition is caused by a hot spot in combustion

chamber from sources such as glowing carbon deposits,

blocked cooling fi ns, an improperly seated valve, or

wrong spark plug(s).

Replacement pistons are available in STD bore size, and

in 0.25 mm (0.010 in.), and 0.50 mm (0.020 in.) oversize.

Replacement pistons include new piston ring sets and

new piston pins.

Replacement ring sets are also available separately

for STD, 0.25 mm (0.010 in.), and 0.50 mm (0.020 in.)

oversize pistons. Always use new piston rings when

installing pistons. Never use old rings.

Some important points to remember when servicing

piston rings:

Piston Style A

1. Cylinder bore must be de-glazed before service ring

sets are used.

2. If cylinder bore does not need re-boring and if old

piston is within wear limits and free of score or scuff

marks, old piston may be reused.

3. Remove old rings and clean up grooves. Never

reuse old rings.

4. Before installing new rings on piston, place top 2

rings, each in turn, in its running area in cylinder

bore and check end gap. Top and center

compression ring end gap clearance is 0.25/0.56

mm (0.010/0.022 in.) with maximum wear limit of

0.94 mm (0.037 in.).

5. After installing new compression (top and middle)

rings on piston, check side clearance. If side

clearance is greater than specifi ed, a new piston

must be used.

Model ECH630-749 engines: Top compression

ring-to-groove side clearance is 0.050/0.095 mm

(0.0019/0.0037 in.). Middle compression ring-to-

groove side clearance is 0.030/0.075 mm

(0.0012/0.00307 in.).

Model CH26, CH735, CH745 engines: Top

compression ring-to-groove side clearance is

0.025/0.048 mm (0.0010/0.0019 in.). Middle

compression ring-to-groove side clearance is

0.015/0.037 mm (0.0006/0.0015 in.).

Piston Style B

1. Cylinder bore must be de-glazed before service ring

sets are used.

2. If cylinder bore does not need re-boring and if old

piston is within wear limits and free of score or scuff

marks, old piston may be reused.

3. Remove old rings and clean up grooves. Never

reuse old rings.

4. Before installing new rings on piston, place top 2

rings, each in turn, in its running area in cylinder

bore and check end gap.

80 mm bore engines: Top compression ring end gap

is 0.100/0.279 mm (0.0039/0.0110 in.). Middle

compression ring end gap is 1.400/1.679 mm

(0.0551/0.0661 in.).

83 mm bore engines: Top compression ring end gap

is 0.189/0.277 mm (0.0074/0.0109 in.). Middle

compression ring end gap is 1.519/1.797 mm

(0.0598/0.0708 in.).

5. After installing new compression (top and middle)

rings on piston, make sure ring-to-groove side

clearance is 0.030/0.070 mm (0.001/0.0026 in.). If

side clearance is greater than specifi ed, a new

piston must be used.

Install New Piston Rings

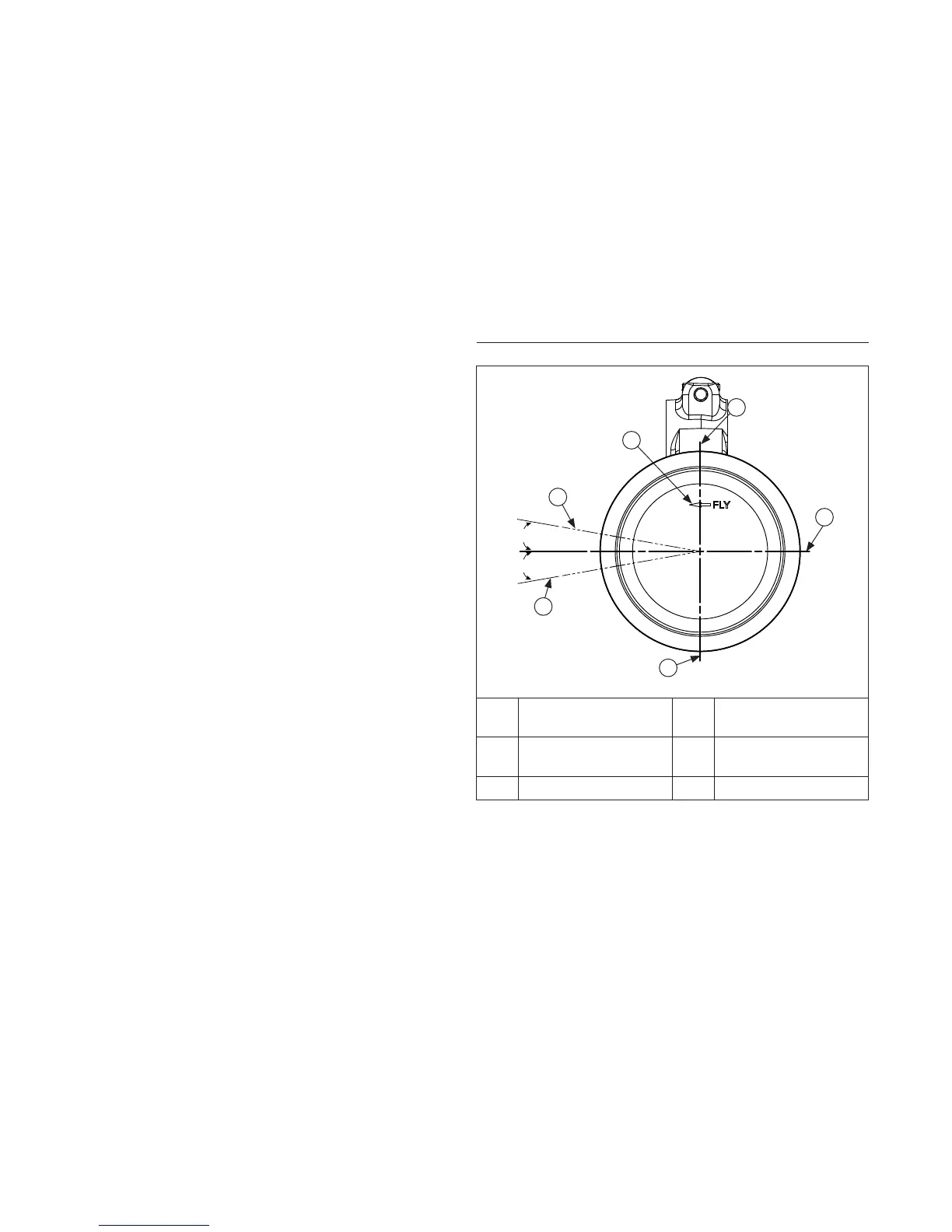

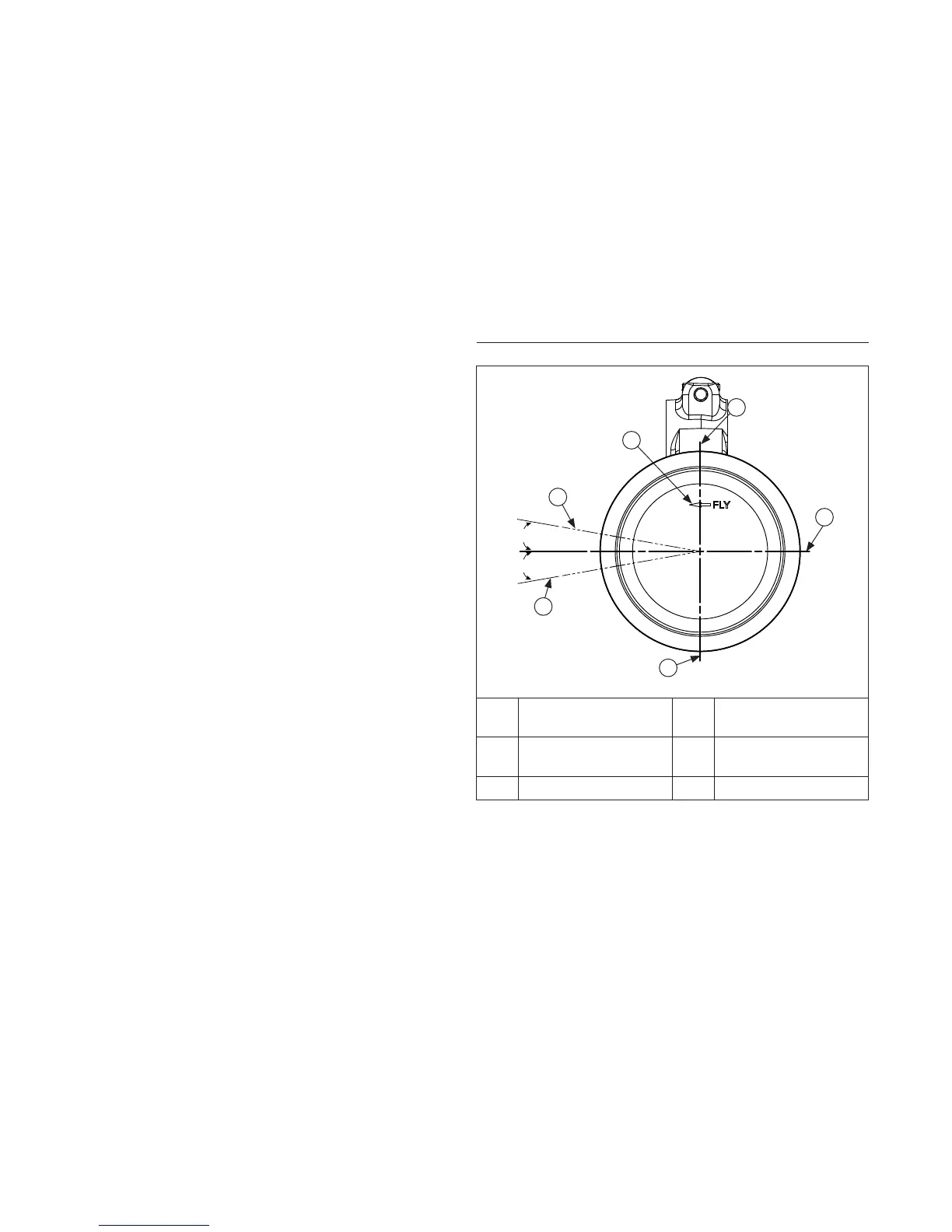

Piston Ring Orientation

10°

10°

F

A

B

C

D

E

A

Top Oil Ring Rail

Gap

B

Bottom Oil Ring Rail

Gap

C

Intermediate Ring

Gap

D

Oil Ring Expander

Gap

E Top Ring Gap F FLY Stamp

NOTE: Rings must be installed correctly. Ring

installation instructions are usually included with

new ring sets. Follow instructions carefully. Use

a piston ring expander to install rings. Install

bottom (oil control) ring fi rst and top

compression ring last.

To install new piston rings, proceed as follows:

1. Oil control ring (bottom groove): Install expander and

then rails. Make sure ends of expander are not

overlapped.

2. Middle compression ring (center groove): Install

center ring using a piston ring installation tool. Make

sure identifi cation mark is up or colored dye stripe

(if contained), is to left of end gap.

3. Top compression ring (top groove): Install top ring

using a piston ring expander. Make sure

identifi cation mark is up or colored dye stripe

(if contained), is to left of end gap.

Disassembly/Inspection and Service

118 24 690 01 Rev. KKohlerEngines.com

Loading...

Loading...