Valve Stem Seals

These engines use valve stem seals on intake valves

and on exhaust valves. Always use a new seal whenever

valve is removed or if seal is deteriorated or damaged in

any way. Never reuse an old seal.

Assemble Cylinder Heads

Prior to installation, lubricate all components with engine

oil, paying particular attention to lip of valve stem seal,

valve stems, and valve guides. Install following items in

order listed below using a valve spring compressor.

• Intake and exhaust valves.

• Valve spring retainers.

• Valve springs.

• Valve spring caps.

• Valve spring keepers.

Install Cylinder Heads

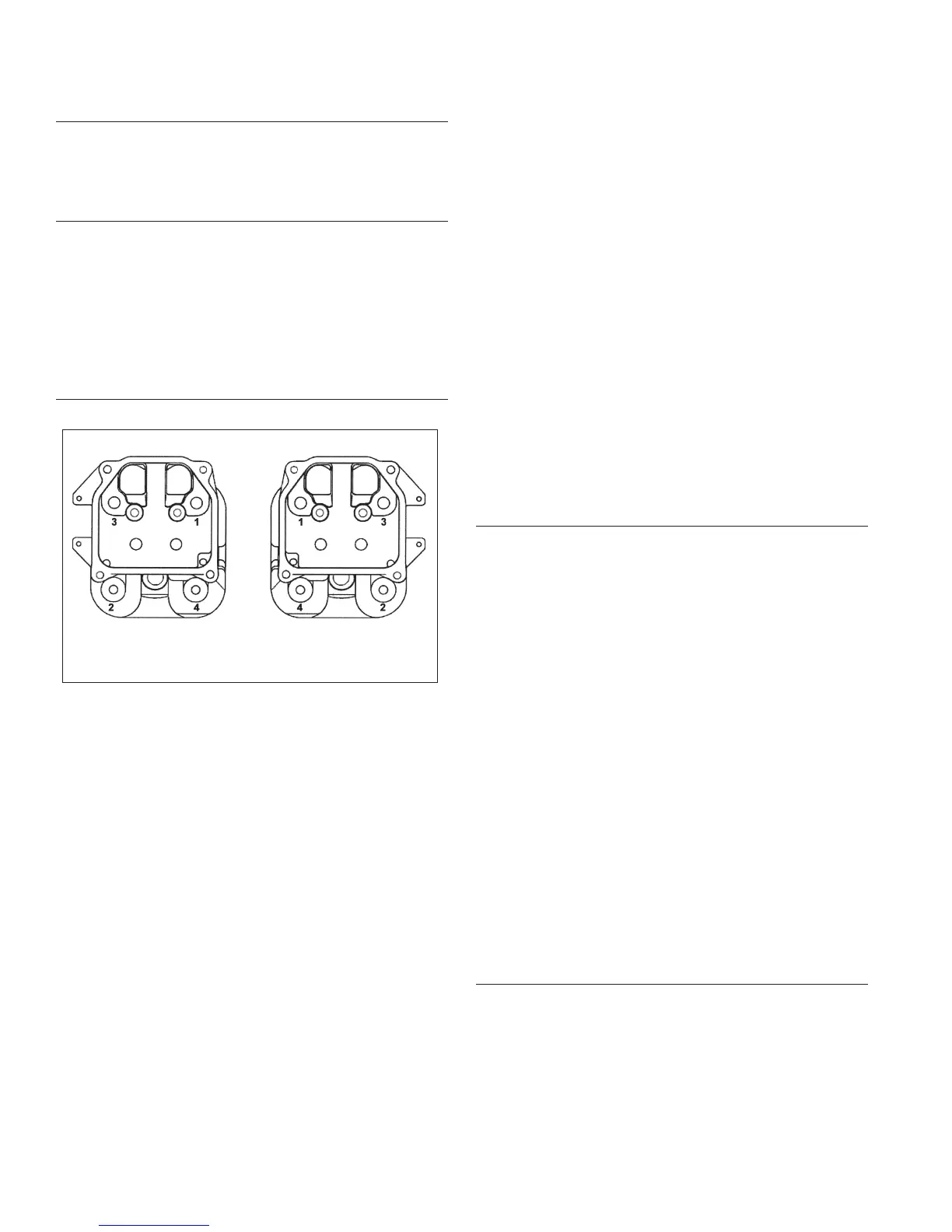

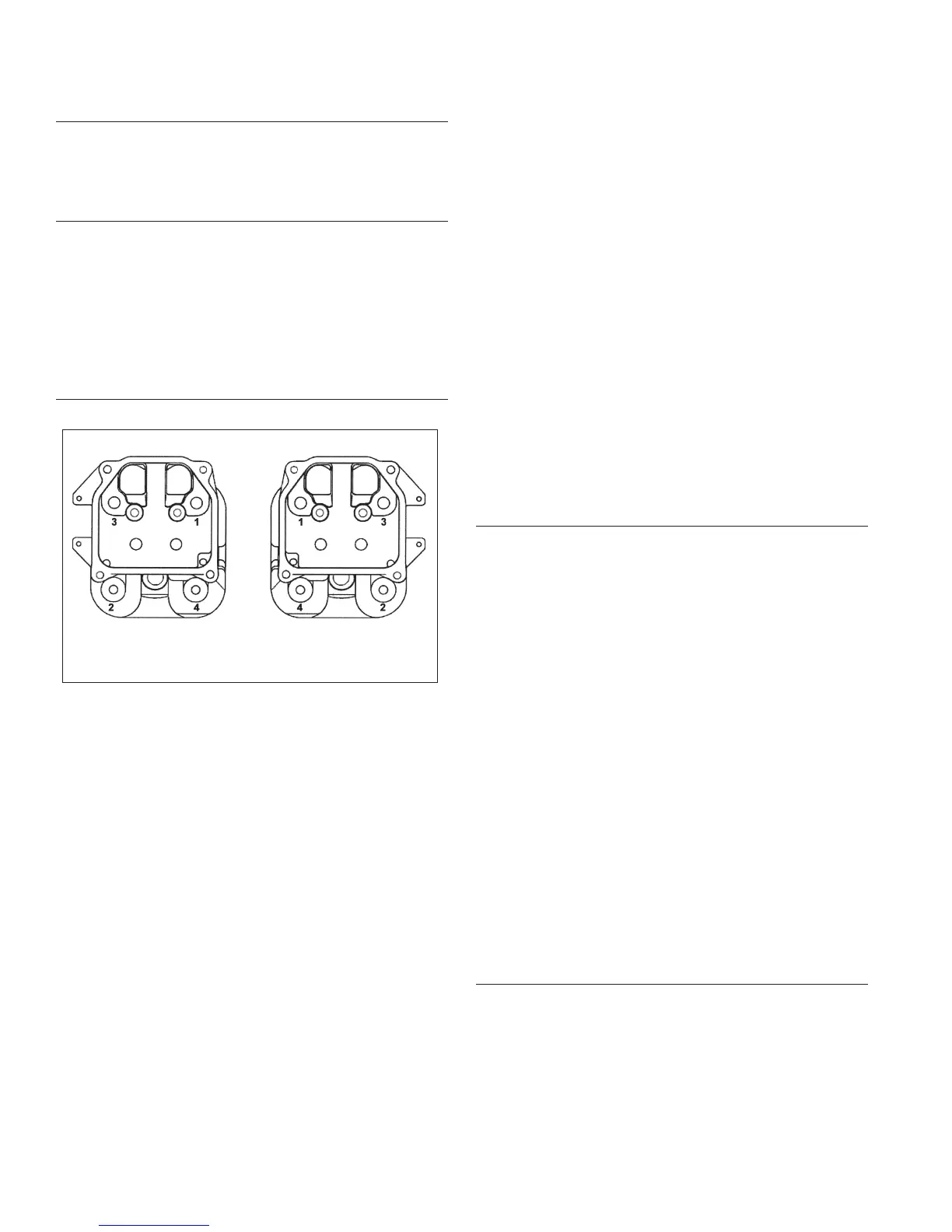

Torque Sequence

#1 #2

NOTE: Cylinder heads must be attached with original

type of mounting hardware, using either screws,

or mounting studs with nuts and washers. Do

not intermix components.

NOTE: Match numbers embossed on cylinder heads

and crankcase.

1. Check to make sure there are no nicks or burrs on

sealing surfaces of cylinder head or crankcase.

Heads secured with mounting studs, nuts, and

washers:

2. If all studs were left intact, go to Step 6. If any studs

were disturbed or removed, install new studs as

described in Step 3. Do not use/reinstall any

loosened or removed studs.

3. Install new mounting stud(s) into crankcase.

a. Thread and lock 2 mounting nuts together on

smaller diameter threads.

b. Thread opposite end of stud with preapplied

locking compound into crankcase until specifi ed

height from crankcase surface is achieved. When

threading in studs, use a steady tightening motion

without interruption until proper height is

obtained. Otherwise, frictional heat from engaging

threads may cause locking compound to set up

prematurely.

Studs closest to lifters must have an exposed height of

75 mm (2 15/16 in.).

Studs furthest from lifters must have an exposed height

of 69 mm (2 3/4 in.).

c. Remove nuts and repeat procedure as required.

4. Check dowel pins are in place and install a new

cylinder head gasket (part number facing up).

5. Install cylinder head. Match numbers on cylinder

heads and crankcase. Make sure head is fl at on

gasket and dowel pins.

6. Lightly lubricate exposed (upper) threads of studs

with engine oil. Install a fl at washer and hex nut onto

each mounting stud. Torque hex nuts in 2 stages;

fi rst to 16.9 N·m (150 in. lb.), fi nally to 33.9 N·m (300

in. lb.). Follow torque sequence.

Heads secured with screws:

2. Install a new cylinder head gasket, (part number

facing up).

3. Install cylinder head and start screws.

4. Torque screws in 2 stages; fi rst to 22.6 N·m (200 in.

lb.), fi nally to 41.8 N·m (370 in. lb.). Follow torque

sequence.

Install Push Rods and Rocker Arms

NOTE: Push rods should always be installed in same

position as before disassembly.

1. Note mark or tag identifying push rod as either

intake or exhaust and cylinder #1 or #2. Dip ends of

push rods in engine oil and install, making sure each

push rod ball seats in its hydraulic lifter socket.

2. Apply grease to contact surfaces of rocker arms and

rocker arm pivots. Install rocker arms and rocker arm

pivots on 1 cylinder head, and start screws.

3. Torque screws to 18.1 N·m (160 in. lb.). Repeat for

other rocker arm.

4. Use a spanner wrench or rocker arm lifting tool (see

Tools and Aids) to lift rocker arms and position push

rods underneath.

5. Repeat above steps for remaining cylinder. Do not

interchange parts from cylinder heads.

6. Rotate crankshaft to check for free operation of

valve train. Check clearance between valve spring

coils at full lift. Minimum allowable clearance is 0.25

mm (0.010 in.).

Check Assembly

Important: Rotate crankshaft a minimum of 2 revolutions

to check longblock assembly and overall proper

operation.

Install Spark Plugs

1. Check gap using wire feeler gauge. Adjust gap to

0.76 mm (0.03 in.).

2. Install plug into cylinder head.

3. Torque plug to 27 N·m (20 ft. lb.).

Reassembly

128 24 690 01 Rev. KKohlerEngines.com

Loading...

Loading...