Install Flywheel

CAUTION

Using improper procedures can lead to broken fragments.

Broken fragments could be thrown from engine. Always

observe and use precautions and procedures when

installing fl ywheel.

Damaging Crankshaft and Flywheel Can

cause personal injury.

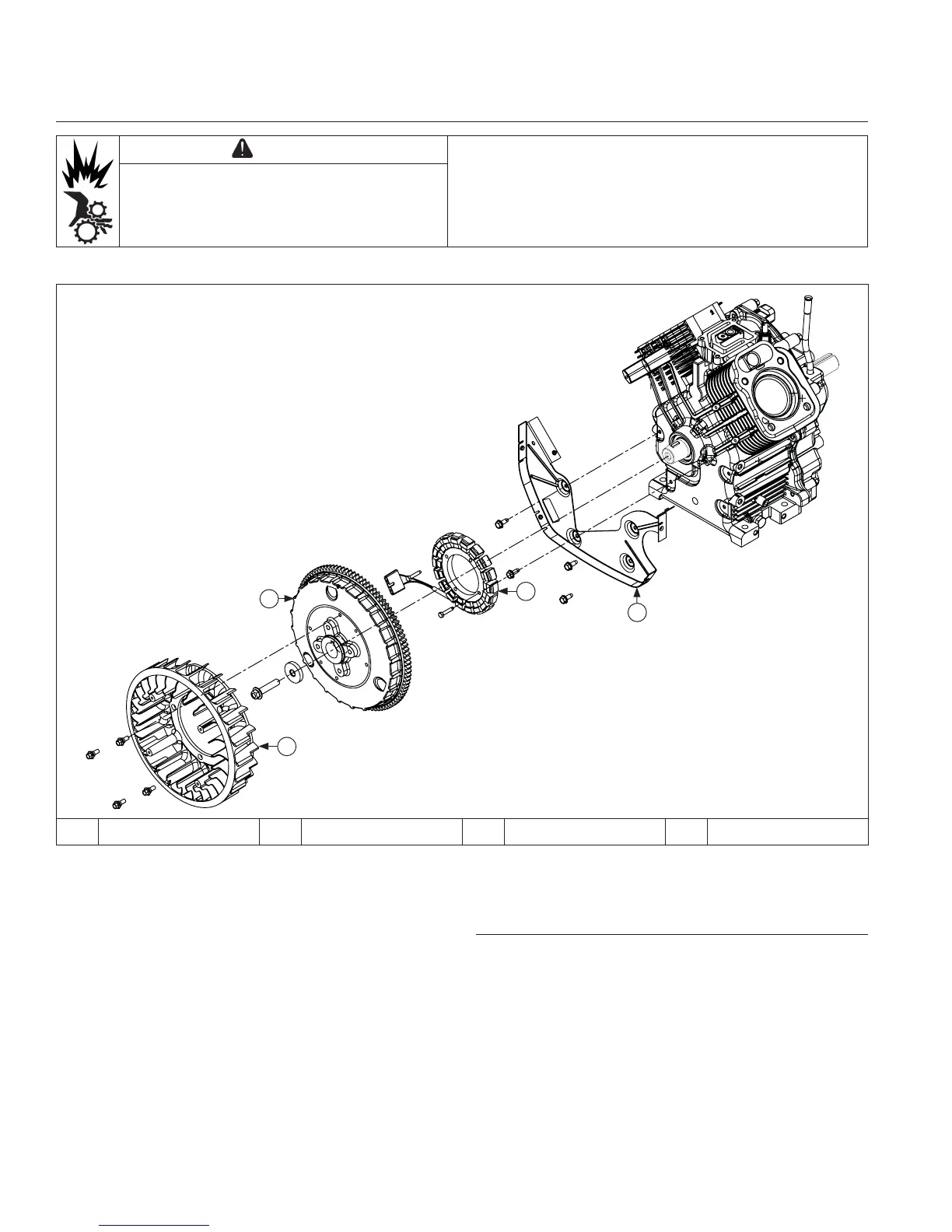

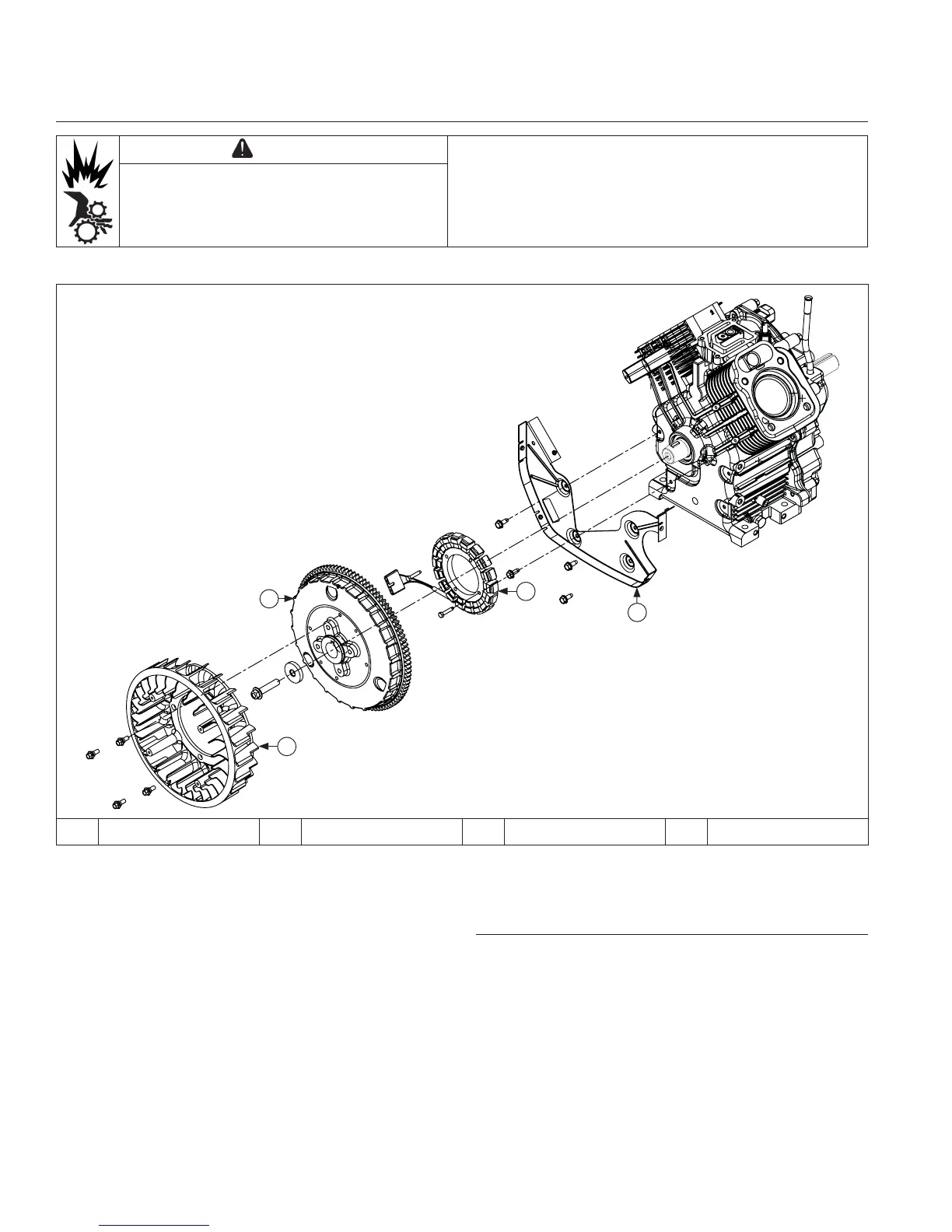

Flywheel Components

A

B

D

C

A Flywheel Fan B Flywheel C Stator D Backing Plate

NOTE: Before installing fl ywheel make sure crankshaft

taper and fl ywheel hub are clean, dry, and

completely free of any lubricants. Presence of

lubricants can cause fl ywheel to be over

stressed and damaged when screw is torqued

to specifi cations.

NOTE: Make sure fl ywheel key is installed properly in

keyway. Flywheel can become cracked or

damaged if key is not properly installed.

1. Install woodruff key into keyway of crankshaft. Make

sure key is properly seated and parallel with shaft

taper.

2. Install fl ywheel onto crankshaft being careful not to

shift woodruff key.

3. Install screw and washer.

4. Use a fl ywheel strap wrench or holding tool to hold

fl ywheel. Torque screw securing fl ywheel to

crankshaft to 71.6 N·m (52.8 ft. lb.).

Install Fan

NOTE: Position locating tabs on back of fan in locating

holes of fl ywheel.

1. Install fan onto fl ywheel using screws (engines with

plastic grass screen). Engines with a metal grass

screen will leave fan loosely assembled.

2. Torque screws to 9.9 N·m (88 in. lb.).

Reassembly

126 24 690 01 Rev. KKohlerEngines.com

Loading...

Loading...