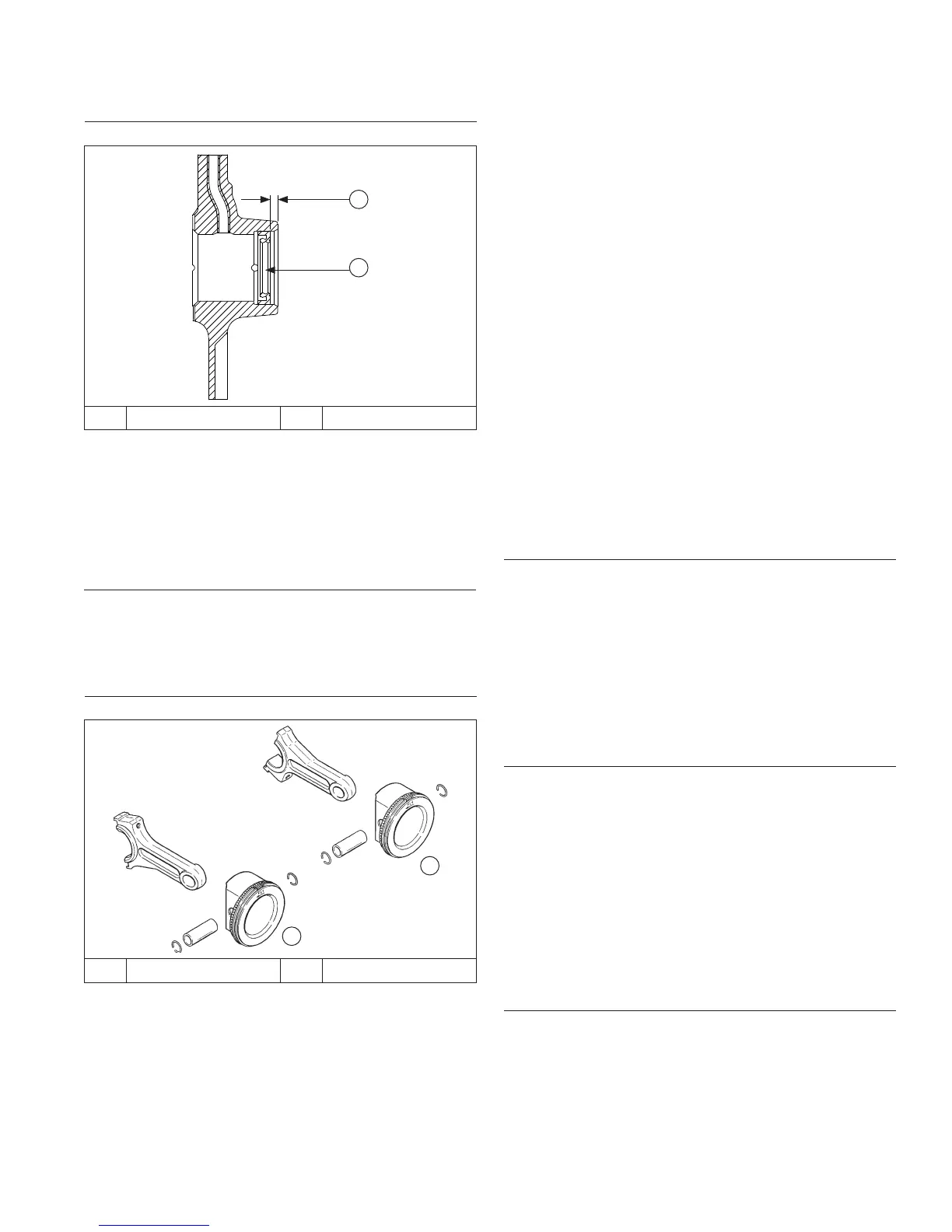

Install Flywheel End Oil Seal

Oil Seal Detail

B

A

A 4.5 mm (0.177 in.) B Oil Seal

1. Make sure seal bore of crankcase is clean and free

of any nicks or burrs.

2. Apply a light coat of clean engine oil to outside

diameter of oil seal.

3. Drive oil seal into crankcase using a seal driver.

Make sure oil seal is installed straight and true in

bore to depth shown.

Install Crankshaft

1. Lubricate crankshaft journals and connecting rod

bearing surfaces with engine oil.

2. Carefully slide fl ywheel end of crankshaft through

main bearing in crankcase.

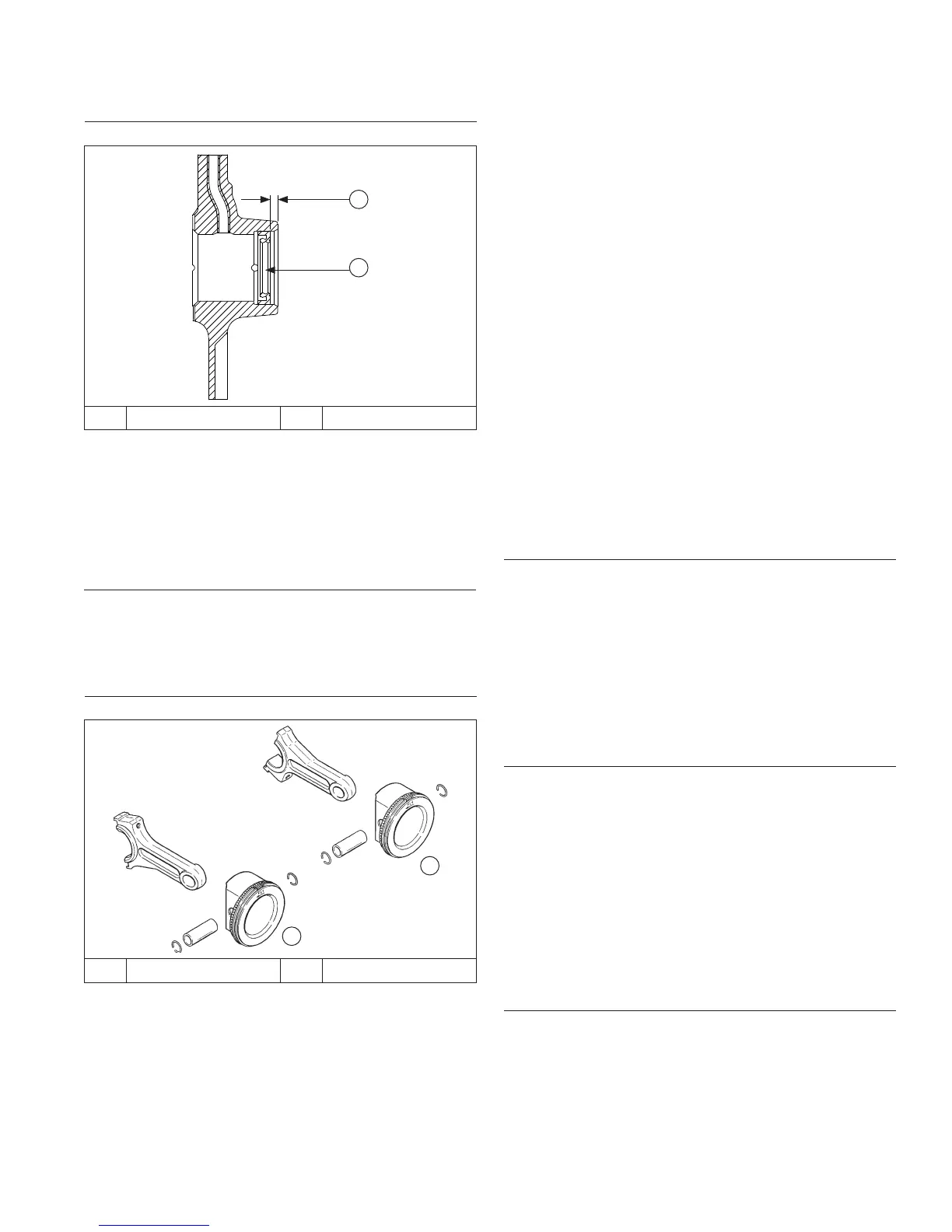

Install Connecting Rods with Pistons and Rings

Piston Detail

A

B

A Cylinder 1 B Cylinder 2

NOTE: Cylinders are numbered on crankcase. Make

sure to install piston, connecting rod and end

cap into its appropriate cylinder bore as

previously marked at disassembly. Do not mix

end caps and connecting rods.

NOTE: Proper orientation of piston/connecting rod

assemblies inside engine is extremely important.

Improper orientation can cause extensive wear

or damage. Be certain pistons and connecting

rods are assembled exactly as shown.

NOTE: Align chamfer of connecting rod with chamfer of

its mating end cap. When installed, fl at faces of

connecting rods should face each other. Faces

with raised rib should be toward outside.

1. If piston rings were removed, see Disassembly/

Inspection and Service procedure to install rings.

2. Lubricate cylinder bore, piston, and piston rings with

engine oil. Compress rings of cylinder 1 piston using

a piston ring compressor.

3. Make sure FLY stamping on piston is facing towards

fl ywheel side of engine. Use a hammer with a rubber

grip and gently tap piston into cylinder. Be careful oil

ring rails do not spring free between bottom of ring

compressor and top of cylinder.

4. Install inner rod cap to connecting rod using screws.

Torque in increments to 11.6 N·m (103 in. lb.).

Illustrated instructions are provided in service rod

package.

5. Repeat above procedure for other connecting rod

and piston assembly.

Install Governor Cross Shaft

1. Lubricate governor cross shaft bearing surfaces in

crankcase with engine oil.

2. Slide small lower washer onto governor cross shaft

and install cross shaft from inside of crankcase.

3. Install nylon washer onto governor cross shaft, then

start push-on retaining ring. Hold cross shaft up in

position, place a 0.50 mm (0.020 in.) feeler gauge on

top of nylon washer, and push retaining ring down

shaft to secure. Remove feeler gauge, which will

have established proper end play.

Install Camshaft

1. Liberally apply camshaft lubricant (see Tools and

Aids) to each cam lobe. Lubricate camshaft bearing

surfaces of crankcase and camshaft with engine oil.

2. Position timing mark of crankshaft gear at 12 o’clock

position.

3. Turn governor cross shaft clockwise until lower end

of shaft contacts cylinder. Make sure cross shaft

remains in this position while installing camshaft.

4. Slide camshaft into bearing surface of crankcase,

positioning timing mark of camshaft gear at 6 o’clock

position. Make sure camshaft gear and crankshaft

gear mesh, with both timing marks aligned.

Oil Pump Assembly

Oil pump is mounted inside closure plate. If service was

required, and oil pump was removed, refer to assembly

procedures under Oil Pump Assembly in Disassembly/

Inspection and Service.

Reassembly

12324 690 01 Rev. K KohlerEngines.com

Loading...

Loading...