Lubrication System

9324 690 01 Rev. K KohlerEngines.com

CHANGE OIL AND FILTER

Change oil while engine is warm.

1. Clean area around oil fi ll cap/dipstick and drain plug.

Remove drain plug and oil fi ll cap/dipstick. Allow oil

to drain completely.

2. Clean area around oil fi lter. Place a container under

fi lter to catch any oil and remove fi lter. Wipe off

mounting surface. Reinstall drain plug. Torque to 10

ft. lb. (13.6 N·m).

3. Place new fi lter in shallow pan with open end up. Fill

with new oil until oil reaches bottom of threads. Allow

2 minutes for oil to be absorbed by fi lter material.

4. Apply a thin fi lm of clean oil to rubber gasket on new

fi lter.

5. Refer to instructions on oil fi lter for proper

installation.

6. Fill crankcase with new oil. Level should be at top of

indicator on dipstick.

7. Reinstall oil fi ll cap/dipstick and tighten securely.

8. Start engine; check for oil leaks. Stop engine; correct

leaks. Recheck oil level.

9. Dispose of used oil and fi lter in accordance with

local ordinances.

OIL COOLER (if equipped)

1. Clean fi ns with a brush or compressed air.

2. Remove screws securing oil cooler and tilt to clean

back side.

3. Reinstall oil cooler and torque to 2.2 N·m (20 in. lb.).

OIL SENTRY

™

(if equipped)

This switch is designed to prevent engine from starting

in a low oil or no oil condition. Oil Sentry

™

may not shut

down a running engine before damage occurs. In some

applications this switch may activate a warning signal.

Read your equipment manuals for more information.

Oil Sentry

™

pressure switch is installed in breather cover.

On engines not equipped with Oil Sentry

™

installation

hole is sealed with a 1/8-27 N.P.T.F. pipe plug.

Installation

1. Apply pipe sealant with Tefl on

®

(Loctite

®

PST

®

592™

Thread Sealant or equivalent) to threads of switch.

2. Install switch into tapped hole in breather cover.

3. Torque switch to 4.5 N·m (40 in. lb.).

Testing

Compressed air, a pressure regulator, pressure gauge,

and a continuity tester are required to test switch.

ECH Models:

Normally Closed Switch

1. Connect continuity tester across blade terminal and

metal case of switch. With 0 psi pressure applied to

switch, tester should indicate continuity (switch

closed).

2. Gradually increase pressure to switch. As pressure

increases through range of 2.0/5.0 psi, tester should

indicate a change to no continuity (switch open).

Switch should remain open as pressure is increased

to 90 psi maximum.

3. Gradually decrease pressure through range of

2.0/5.0 psi. Tester should indicate a change to

continuity (switch closed) down to 0 psi.

4. Replace switch if it does not operate as specifi ed.

Normally Open Switch

1. Connect continuity tester across blade terminal and

metal case of switch. With 0 psi pressure applied to

switch, tester should indicate no continuity (switch

open).

2. Gradually increase pressure to switch. As pressure

increases through range of 2.0/5.0 psi, tester should

indicate a change to continuity (switch closed).

Switch should remain closed as pressure is

increased to 90 psi maximum.

3. Gradually decrease pressure through range of

2.0/5.0 psi. Tester should indicate a change to no

continuity (switch open) down to 0 psi.

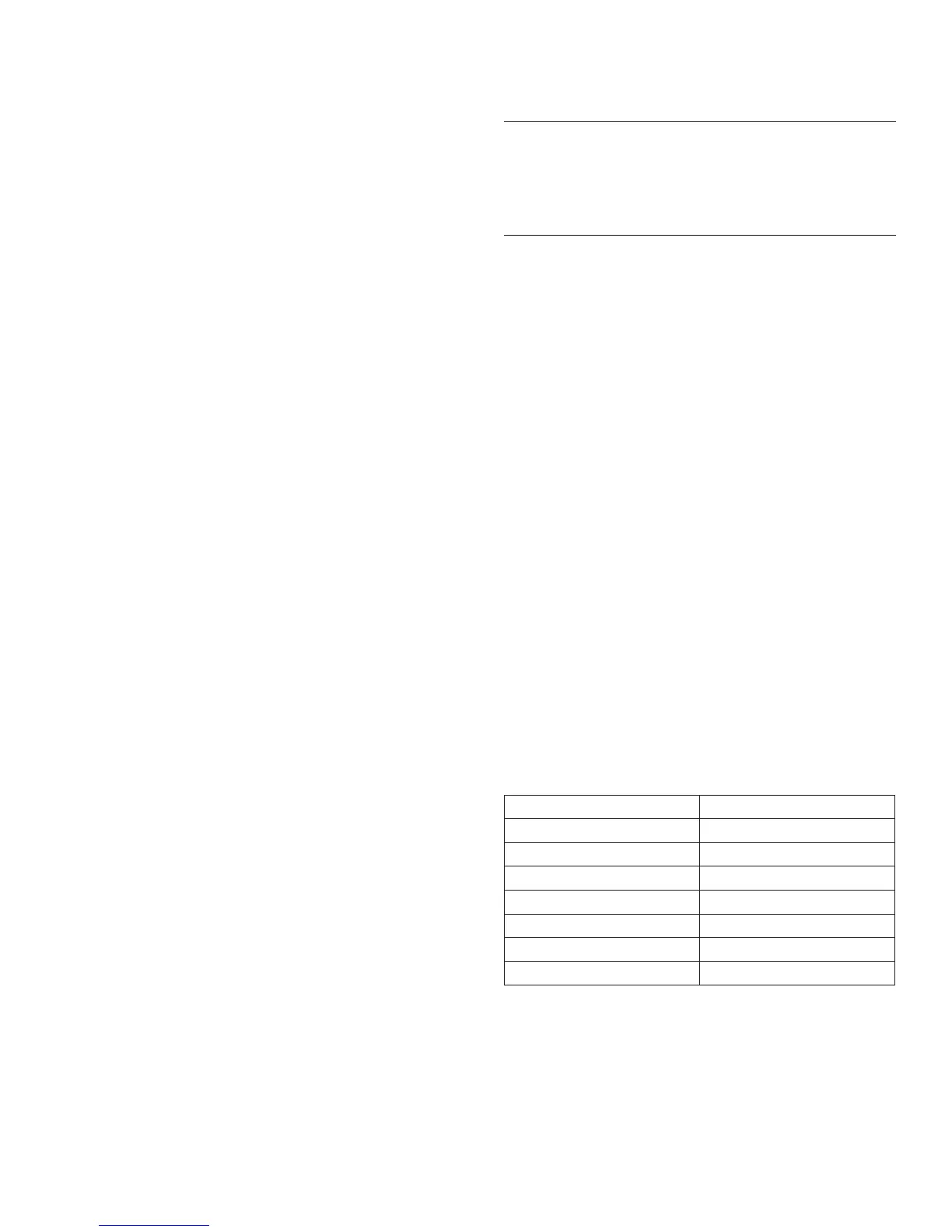

CH Models:

Pressure Switch PSI

12 099 04 2-6

24 099 03 2-5

25 099 27 2-5

28 099 01 2-6

48 099 07 12-16

52 099 08 7-11

52 099 09 7-11

Loading...

Loading...