METHOD FOR ADJUSTING IDLER CLEARANCE

Since the idlers are forced to move forward and backward by an external force, guide plates will be worn out.

Wear of guide plates will cause the vibration of idlers from side to side or inclination of the idlers, and running off

of track links from the idlers or unevenly worn idler and links may result.

Adjust as follows.

1.

Drive the machine by 1 to 2 m (3 ft 3 in to 6 ft 7 in) on a flat place.

2.

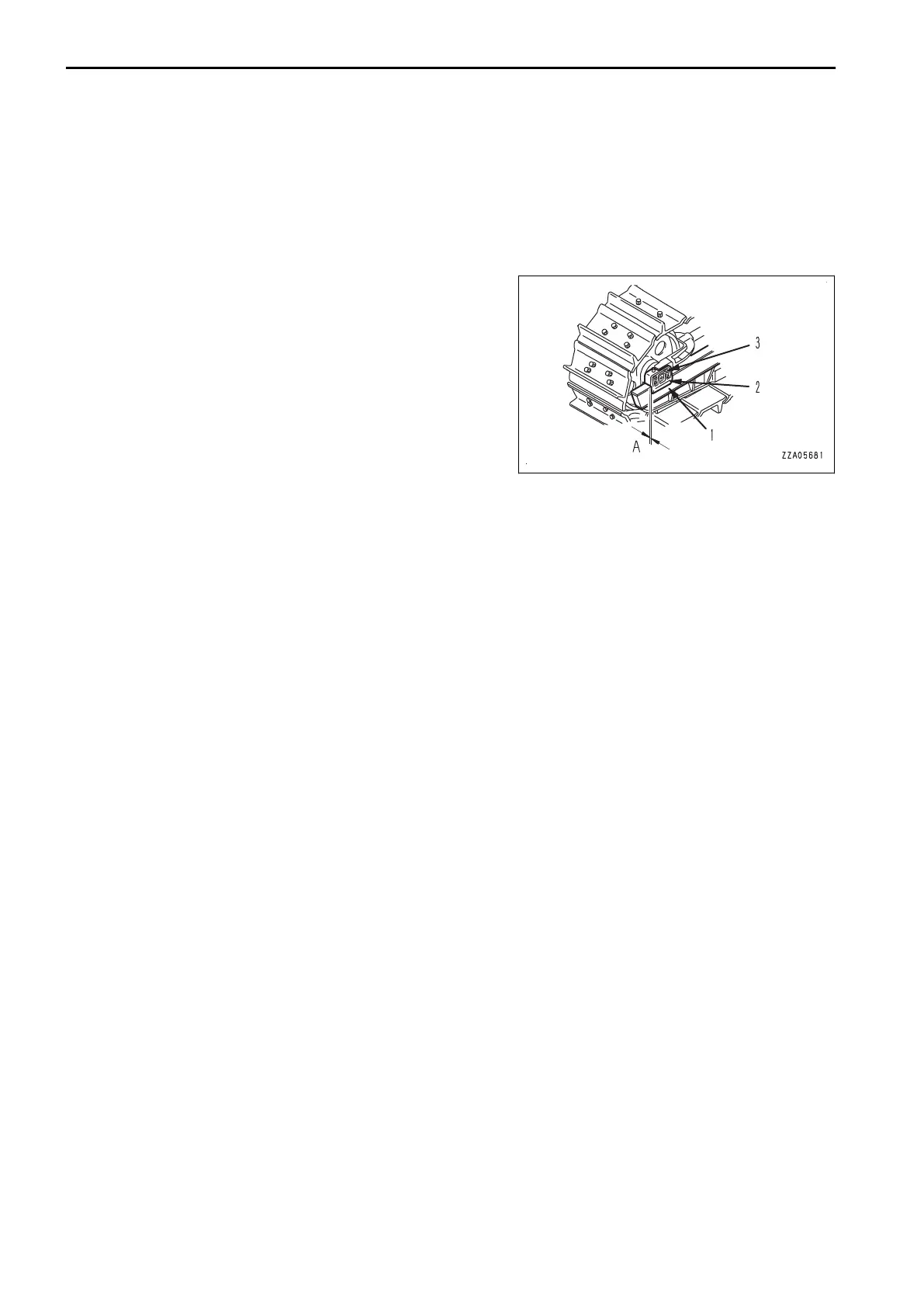

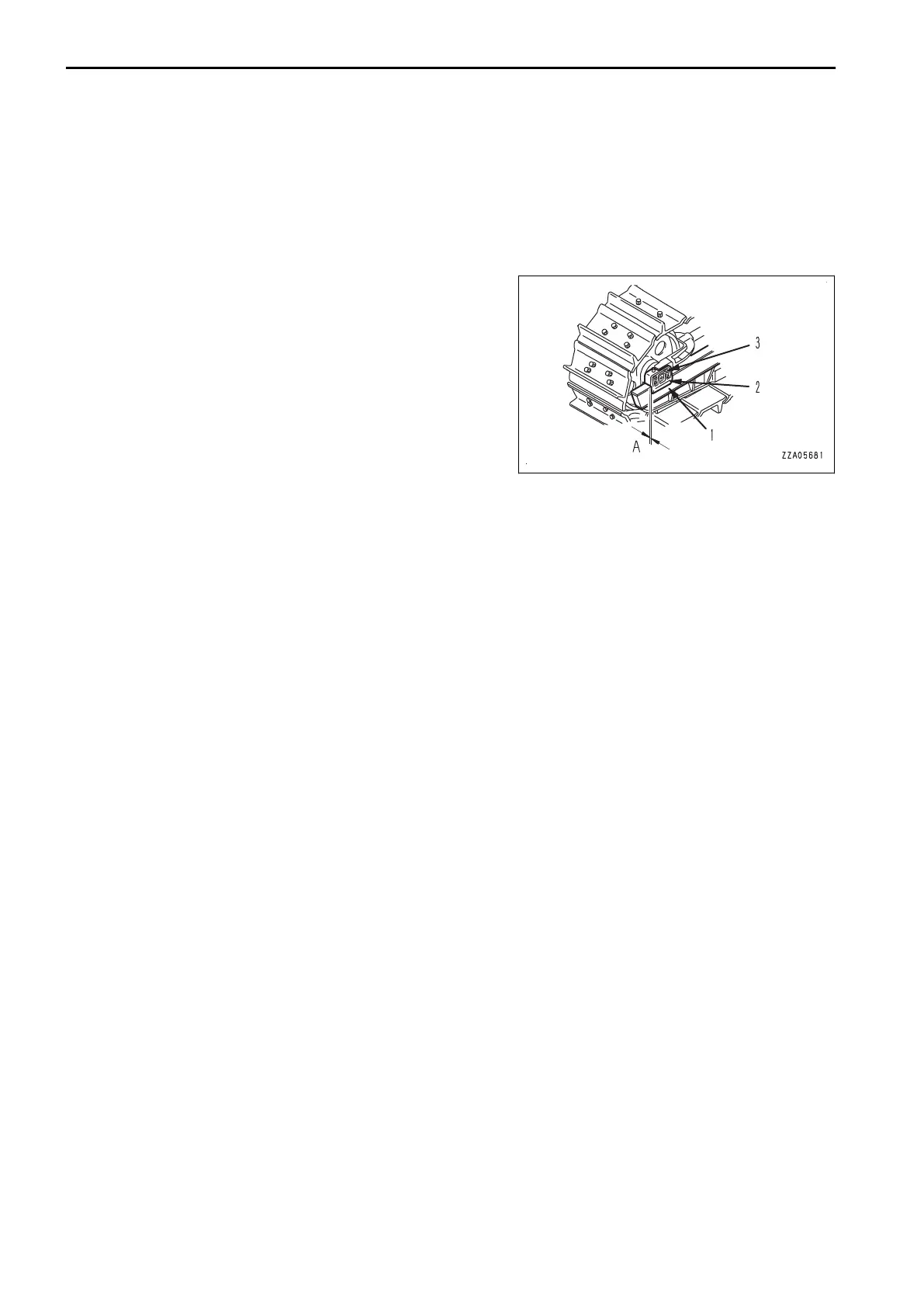

Measure clearance (A) between track frame (1) and guide

plate (2) (4 places on the right and left, and inside and out-

side).

• When clearance (A) is less than 4 mm (0.16 in).

The clearance of the idler does not need to be adjust-

ed.

• When clearance (A) is 4 mm (0.16 in) or more

Adjust the clearance of the idler.

1)

Loosen bolt (3).

2)

Remove some shims and adjust the clearance on

each side to 0.5 to 1 mm (0.02 to 0.04 in).

Thickness of 1 shim is 1 mm (0.04 in).

MAINTENANCE PROCEDURE MAINTENANCE

4-28

Loading...

Loading...