METHOD FOR BLEEDING AIR FROM HYDRAULIC CIRCUIT

Since the engine must be started and the blade must be operated, see OPERATION.

For the starting procedure of the engine, see “METHOD FOR STARTING ENGINE (3-193)”.

NOTICE

If the engine is run at high speed immediately after startup or a cylinder is pushed up to its stroke end,

air taken inside the cylinder may cause damage to the piston packing.

1.

Start the engine.

2.

Run the engine at low idle.

3.

Move each cylinder of the work equipment to approximately 100 mm {3.9 in} before the stroke end, and re-

peat extension and retraction for 5 minutes.

Take care not to move the cylinder to the stroke end.

4.

Run the engine at high idle (max. speed).

5.

Move each cylinder of the work equipment to approximately 100 mm {3.9 in} before the stroke end, and re-

peat extension and retraction for 5 minutes.

Take care not to move the cylinder to the stroke end.

6.

Run the engine at low idle and operate each cylinder 4 to 5 times to the end of its stroke to completely

remove the air.

METHOD FOR LUBRICATING

1.

Lower the work equipment to the ground.

2.

Stop the engine.

3.

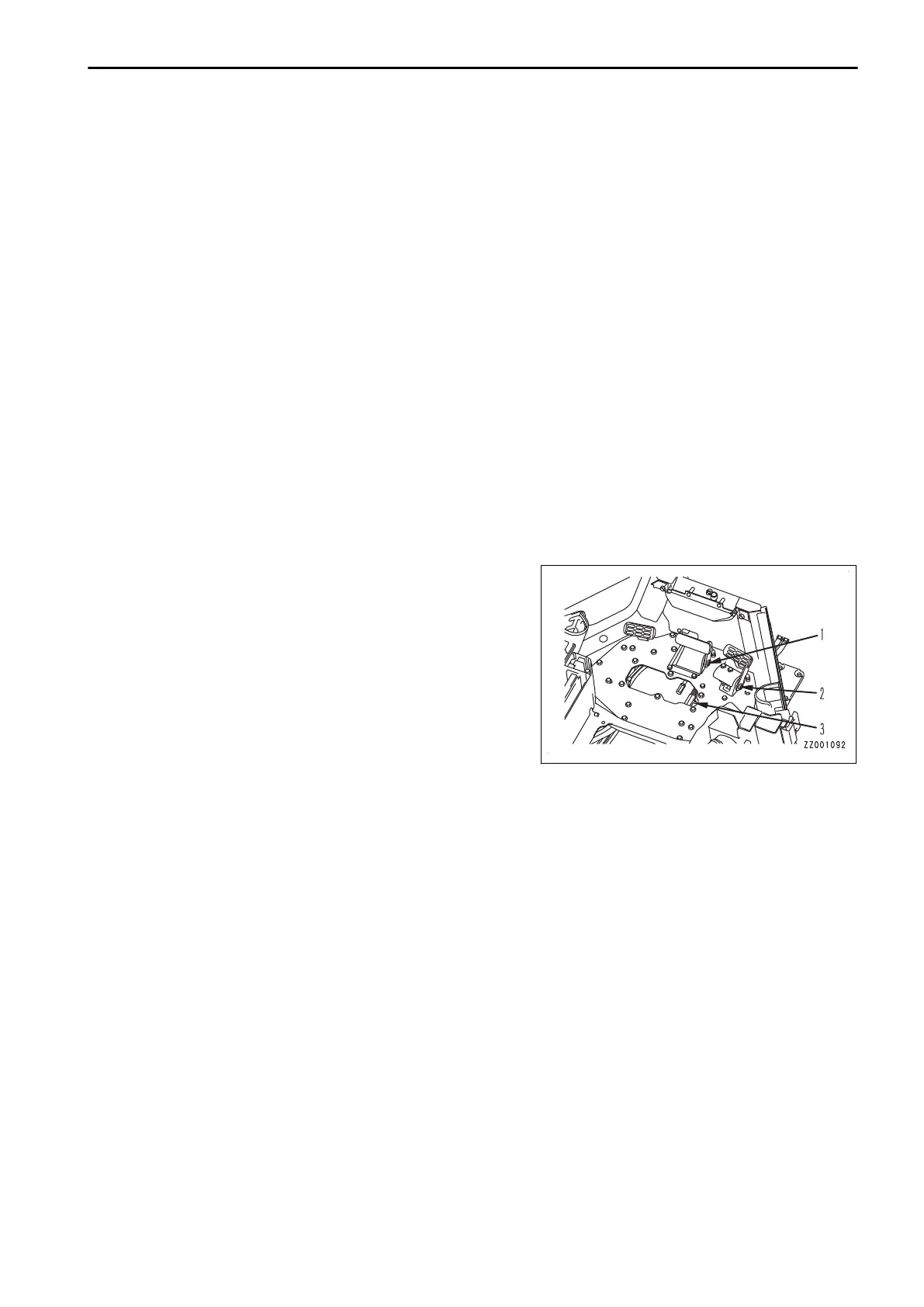

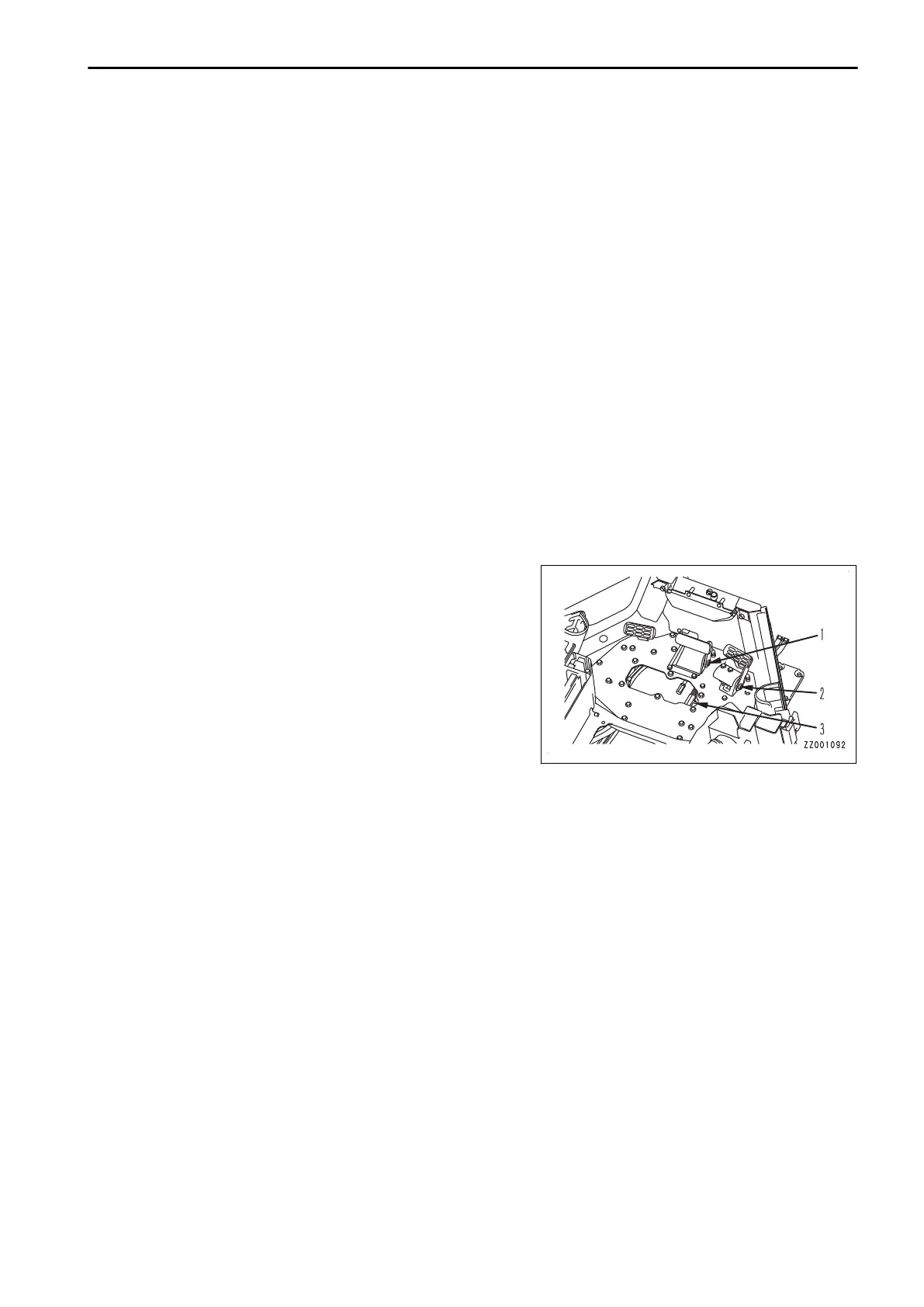

Remove the cover under the monitor and control panel.

4.

By using a grease pump, pump in grease through the

grease fittings.

(1) Brake pedal

(2) Decelerator pedal

(3) Brake rod

5.

After greasing, wipe off any old grease that is pushed out.

MAINTENANCE MAINTENANCE PROCEDURE

4-43

Loading...

Loading...