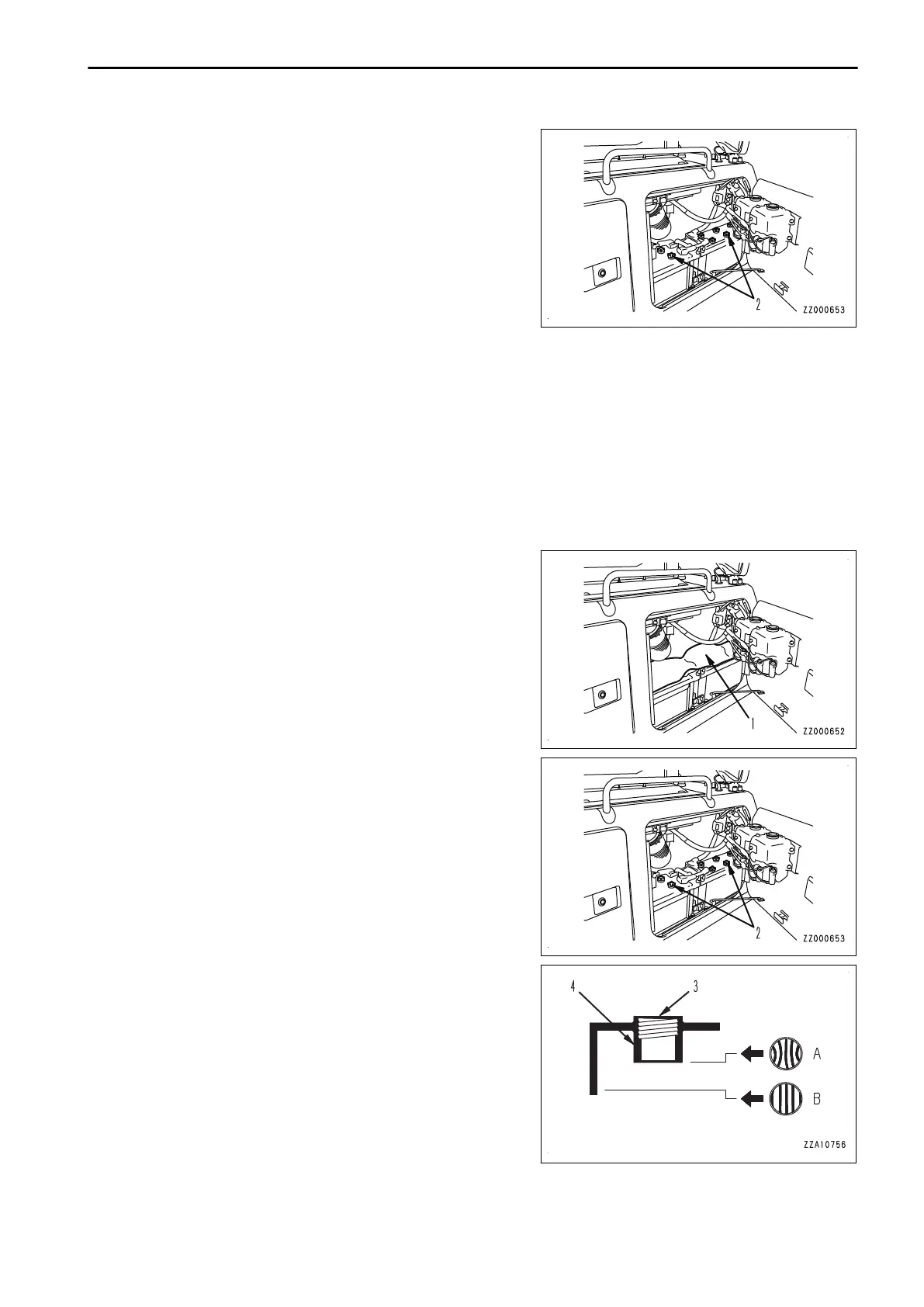

2)

Remove cap (2) immediately and add purified water

(example: commercially available battery liquid) up to

UPPER LEVEL (U.L.) line.

3)

After adding the purified water, tighten cap (2) secure-

ly.

REMARK

If purified water is added to above U.L. line, use a syringe to lower the level to U.L. line. Neutralize the removed

fluid with baking soda (sodium bicarbonate), then flush it away with a large amount of water. If necessary, con-

sult your Komatsu distributor or a battery manufacturer.

METHOD FOR CHECKING ELECTROLYTE LEVEL WHEN IT IS IMPOSSIBLE TO

CHECK FROM SIDE OF BATTERY

If it is impossible to check the electrolyte level from the side of the battery, or there is no UPPER LEVEL line on

the side of the battery, check as follows.

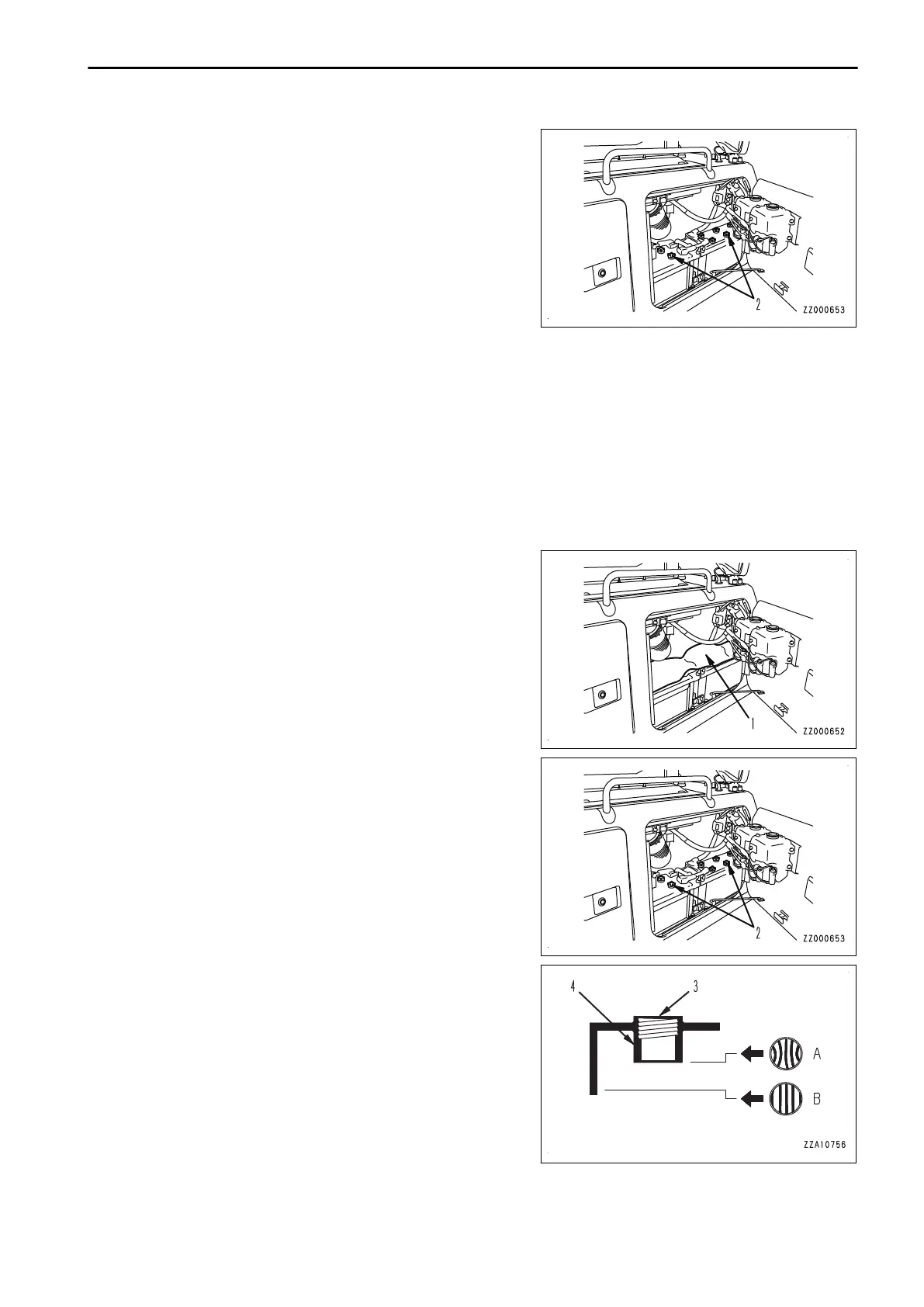

1.

Open the battery inspection cover at the rear left of the machine.

2.

Remove the vinyl sheet (1) installed above the battery.

3.

Remove caps (2) from the top of the battery.

4.

Look into fluid filler port (3) and check the electrolyte level.

(A) Correct level: Electrolyte level is up to bottom of

sleeve, so surface tension causes electrolyte surface to

bulge and pole plate appears to be warped.

(B) Low: Electrolyte level is not up to bottom of sleeve, so

poles appear straight and not bent.

If the electrolyte does not reach sleeve (4), always add the

purified water (such as a commercial battery fluid) so that

the level reaches the bottom of sleeve (4) (UPPER LEV-

EL).

5.

After checking adding the purified water, tighten cap (2)

securely.

MAINTENANCE MAINTENANCE PROCEDURE

4-59

Loading...

Loading...