OPERATION TROUBLESHOOTING

3-137

RELEASING BRAKE

CAUTION

When a machine is towed, the brakes must be fully released. If the brakes are partially applied, this may

lead to overheating and damage to the brakes.

To release the brakes, set the pump pressure to 2.7 to 3.1 MPa (28 to 32 kg/cm2, 398 to 454 PSI).

If the pump pressure exceeds 3.1 MPa (32 kg/cm2, 454 PSI), the components of the brake may be dam-

aged.

When towing, leakage from the oil pressure circuit will cause the pump pressure to go down with time.

Always keep the pump pressure above 1.8 MPa (18 kg/cm2, 213 PSI) when towing. If the pressure goes

below 1.8 MPa (18 kg/cm2, 213 PSI) during the towing

operation, stop the operation, pump the handle of the brake release pump, and raise the pump pressure to

2.7 to 3.1 MPa (28 to 32 kg/cm2, 398 to 454 PSI).

When towing, do not use the brakes to control the travel speed of the machine. This will further damage

the brakes and there may be defective operation of the brake system.

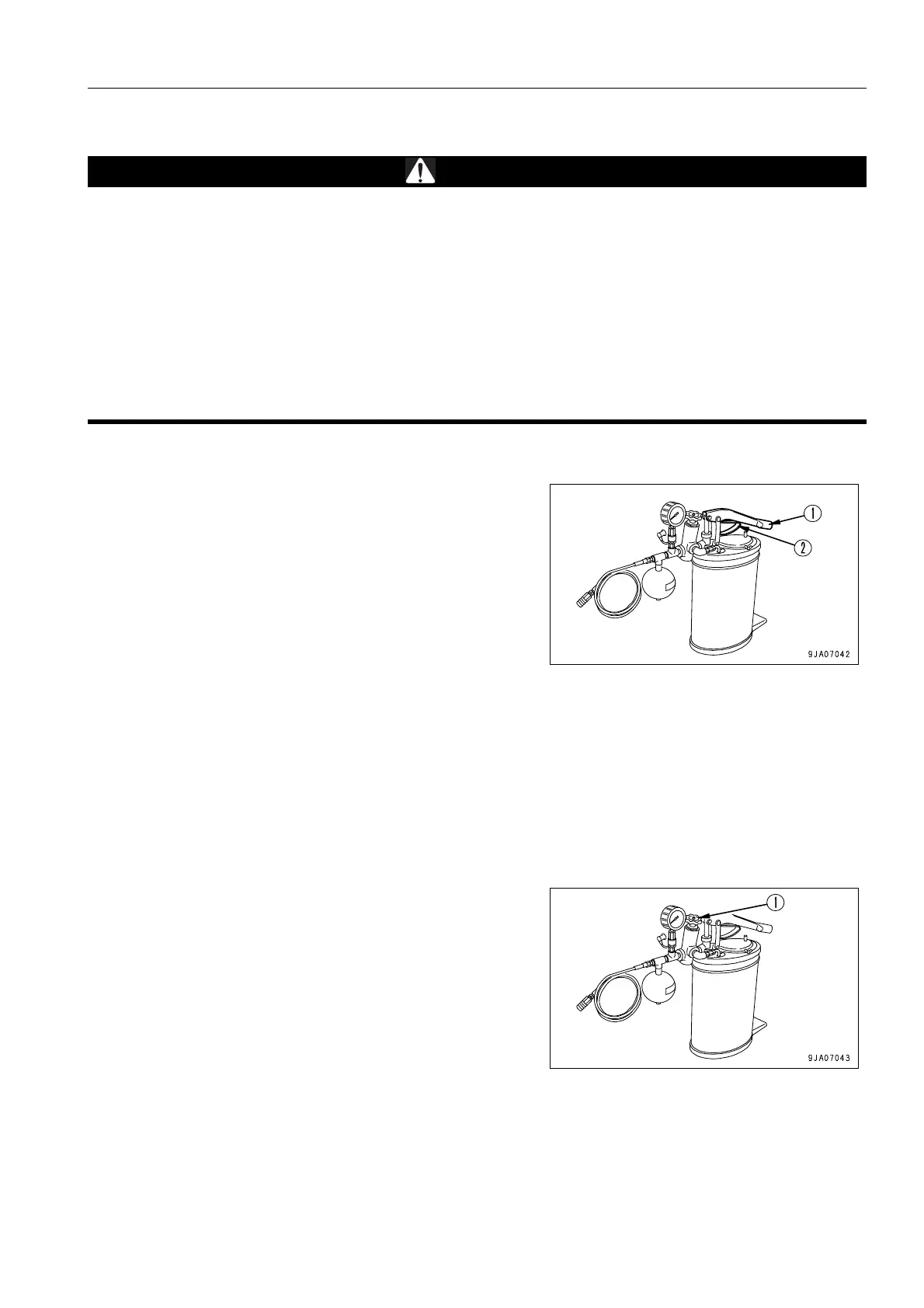

1. Operate handle (1) of the brake release pump and send

pressure oil to the brake circuit until it reaches the specified

pressure.

Specified pump pressure: 2.75 to 3.14 MPa (28.0 to 32.0

kg/cm2, 398 to 454 PSI)

REMARK

If it is necessary to move the brake release pump during the

operation, hold lever (2) under handle (1) and move the pump.

2. It is now possible to tow the machine.

Remove the blocks, and tow the machine at a speed of

less than 2 km/h (1.2 MPH).

OPERATING BRAKE

After completion of the towing operation, apply the brake to prevent the machine from moving.

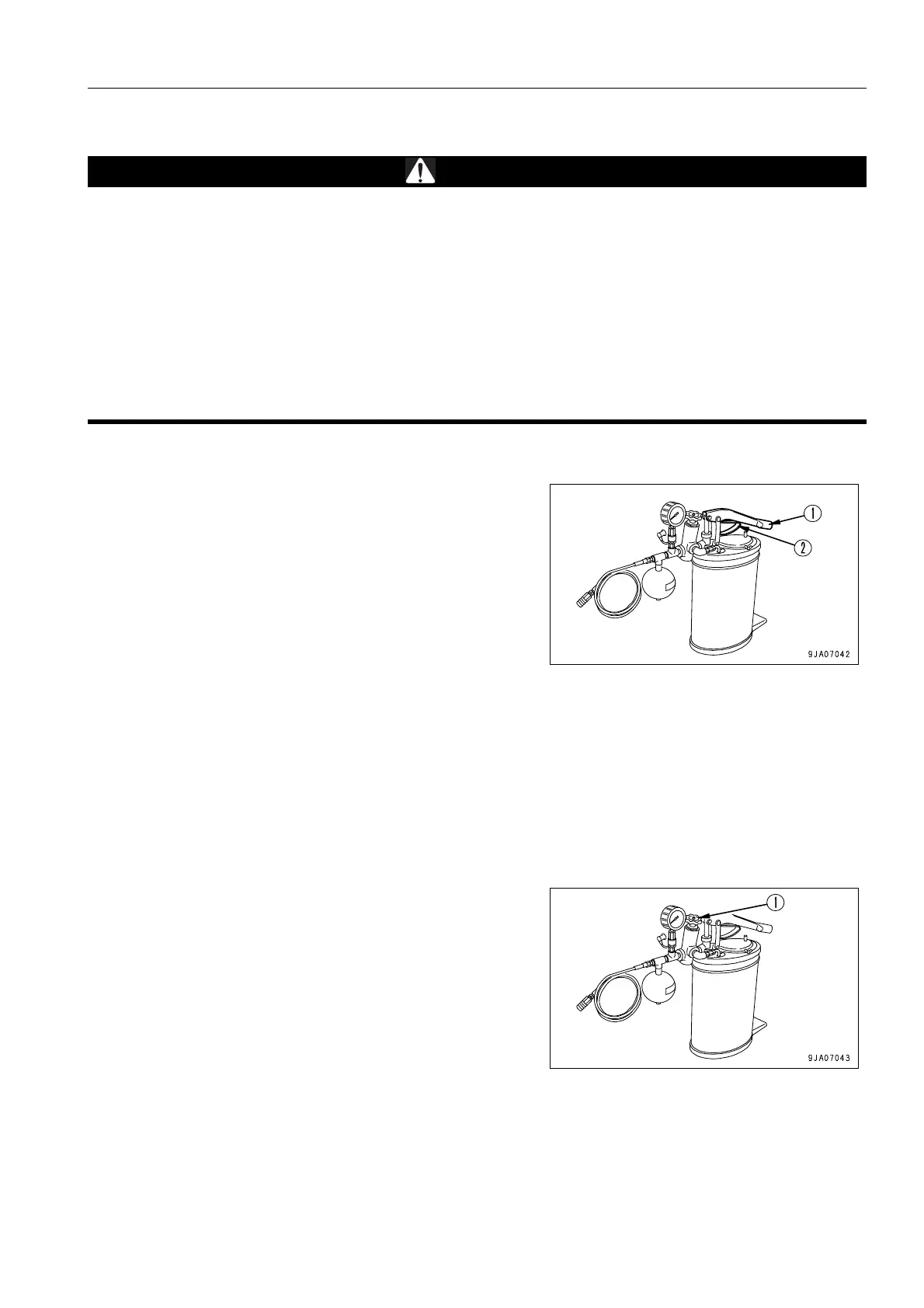

To apply the brake, turn relief handle (1) of the brake release

pump to release the pressure.

Loading...

Loading...