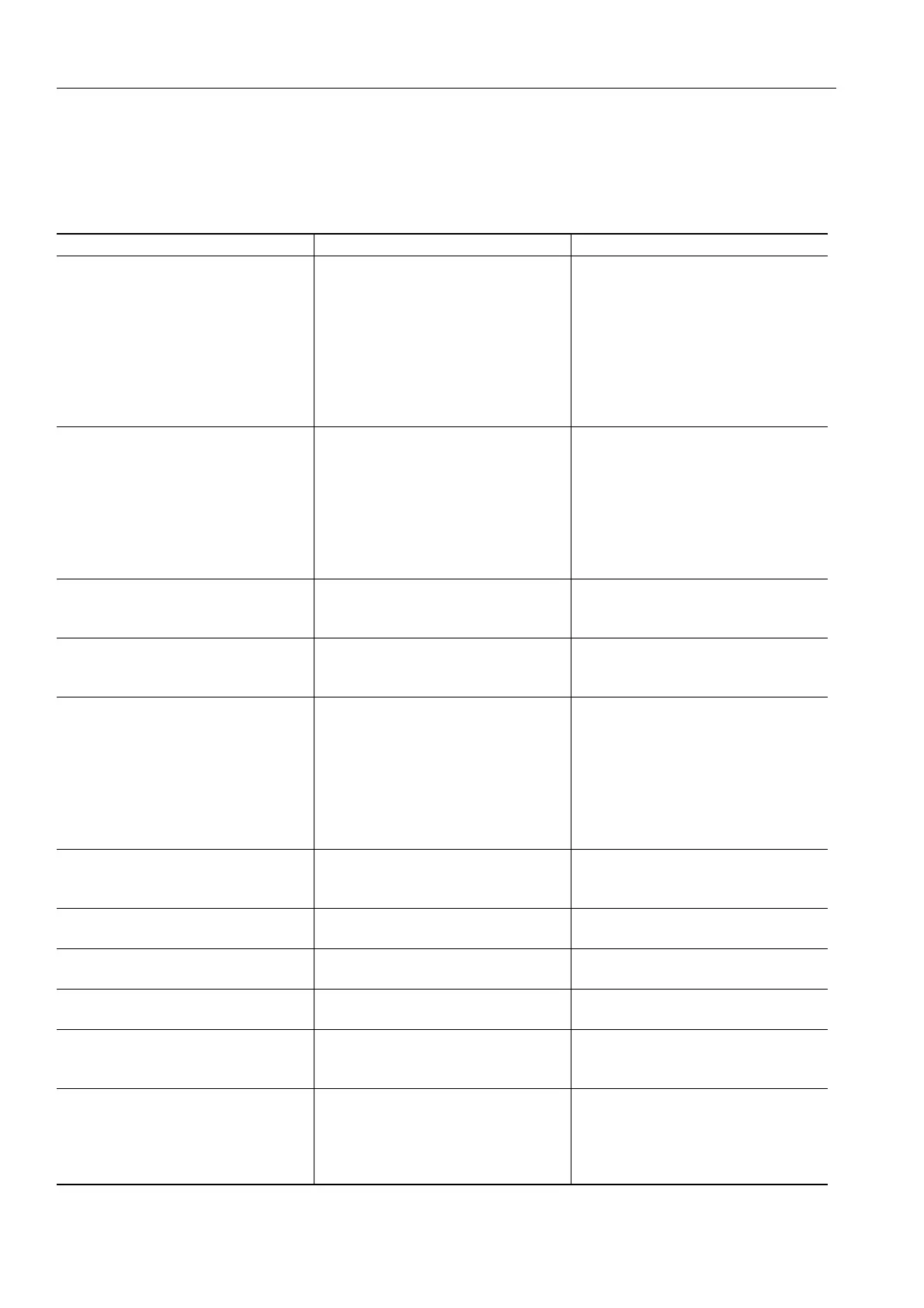

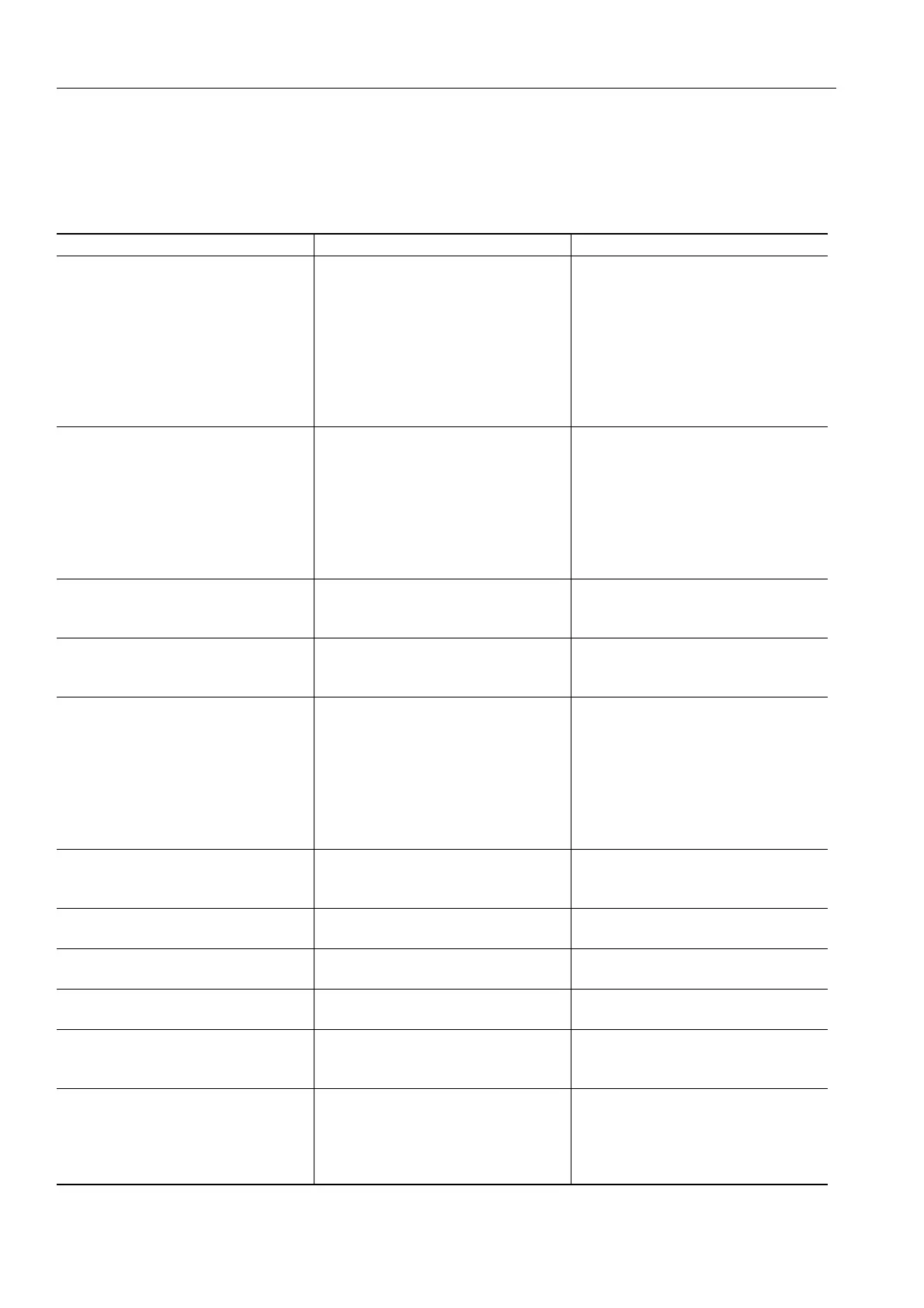

TROUBLESHOOTING OPERATION

3-144

CHASSIS 3

q ( ): Always contact your Komatsu distributor when dealing with these items.

q In cases of problem or causes which are not listed below, contact your Komatsu distributor for repairs.

Problem Main causes Remedy

Oil pressure in torque converter fails

to rise

•Improper tightening of oil pipe, pipe

joint, air leaking in or oil leaking out

because of damage

•Wear, scuffing of gear pump

•Insufficient oil in power train case

•Clogged oil filter element strainer in

power train case

•Check, repair

(•Check, replace)

•Add oil to the specified level. For

details, see CHECK BEFORE

STARTING

•Clean. For details, see EVERY 500

HOURS SERVICE

Torque converter is overheated

•Clogged radiator

•Engine coolant temperature is high

•Clogged oil cooler

•Oil pressure too low

•Lack of flow of lubricant caused by

wear of power train gear pump

•Clean radiator core

•See ENGINE related parts

(•Clean or repalce)

•Go to “Oil pressure in torque con-

verter fails to rise“

(•Replace gear pump)

Torque converter oil temperature

gauge does not work

•Defective oil temperature gauge

•Defective contact in wiring connec-

tion

(•Replace oil temperature gauge)

(•Check, repair)

Lacks drawbar pull (machine does

not pick up speed)

•Lack of engine horsepower

•Oil pressure in torque converter is

too low

•See ENGINE related parts

•Go to “ Oil pressure in torque con-

verter fails to rise“

Machine will not move when steer-

ing, forward-reverse, gear shift lever

is placed in FORWARD

•Insufficient oil in power train case

•Transmission oil pressure does not

rise

•Defective Brake

•Defective lever wiring

•Parking brake lever is in LOCK

position

•Add oil to specified level. For

details, see CHECK BEFORE

STARTING

•Go to oil pressure in torque con-

verter fails to rise

(•Adjust linkage)

(•Check, repair)

•Set to FREE position

Does not steer even when steering

is operated

•Defective lever wiring

•Abnormal HSS pump

•Abnormal HSS motor

(•Check, repair)

(•Check, replace)

(•Check, replace)

Machine doesn't stop when brake

pedal are depressed

•Defective brake adjustment (•Adjust linkage)

(•Check brake pressure)

Track comes off

•Track is too loose •Adjust track tension. For details,

see WHEN REQUIRED

Sprocket develops abnormal wear

•Track is too loose or too tight •Adjust track tension. For details,

see WHEN REQUIRED

Machine does not travel in straight

line

•Defective adjustment of HSS con-

troller

•Abnormal HSS pump

(•Adjust)

(•Replace)

Blade rises too slowly or does not

rise at all

(or blade tilts too slowly)

•Lack of hydraulic oil

•Defective hydraulic pump

•Work equipment lock lever is in

LOCK position

•Add oil to specified level. For

details, see EVERY 250 HOURS

SERVICE

•Check

•Set to FREE position

Loading...

Loading...