12-12

140-3 SERIES

TESTING AND ADJUSTINGMEASURING COMPRESSION RESSURE, MEASURING BLOW-BY PRESSURE

8.

After completing the measurement, remove the

measurement equipment and set to the original

condition.

★ Install the fuel injector and fuel high-pressure

tube as follows.

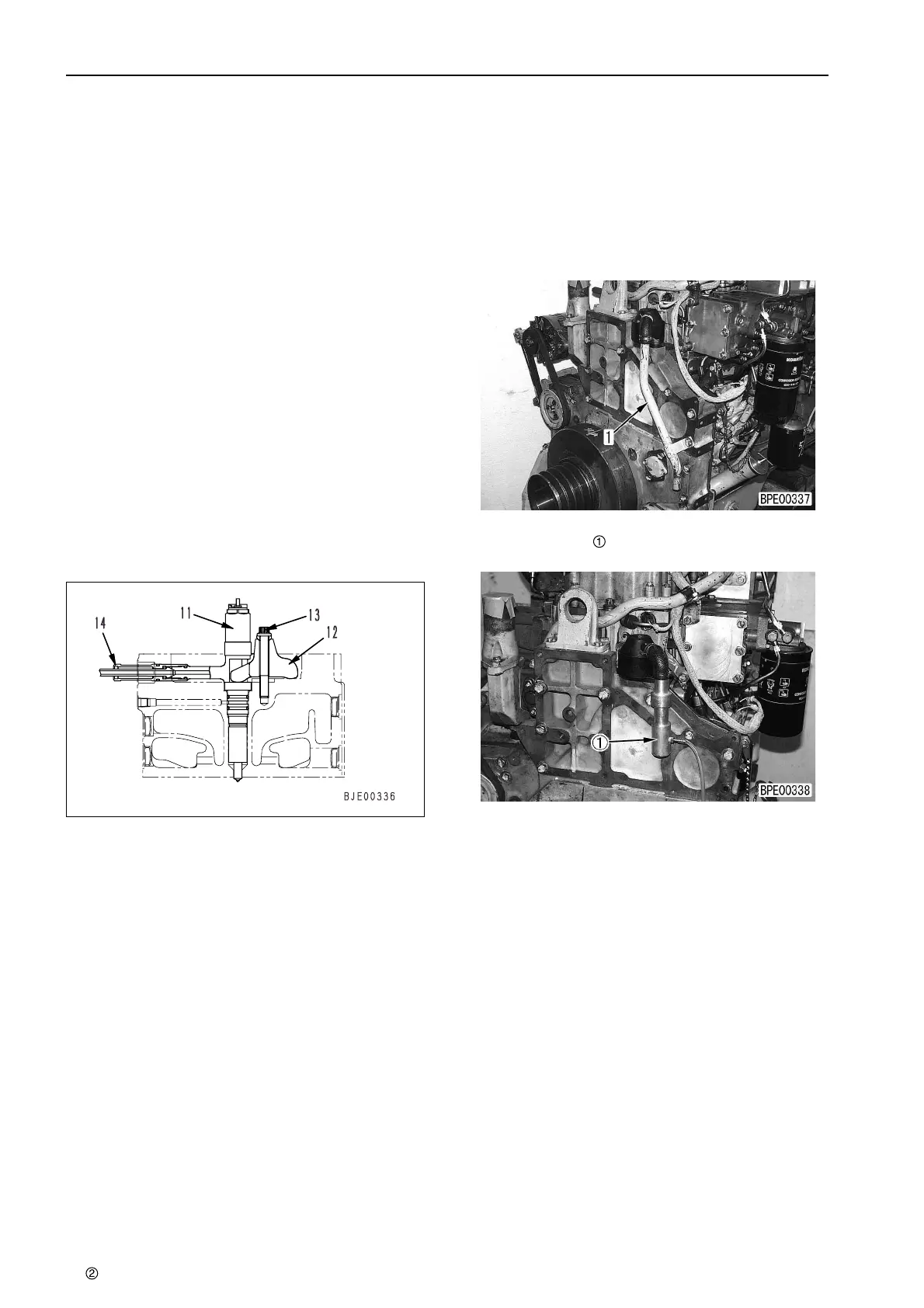

1) Assemble holder (12) to injector (11), then

set in the mounting position on the cylinder

head.

2) Temporarily tighten mounting bolt (13).

★ Tighten so that the injector can still

move.

3) Temporarily tighten tube sleeve (14) to injec-

tor (11).

★ Tighten until it contacts the injector and

stops.

4) Tighten mounting bolt (13) fully.

3

Mounting bolt:

58.8 – 73.5 Nm {6.0 – 7.5 kgm}

5) Tighten tube sleeve (14) fully.

3

Sleeve:

39.2 – 49.0 Nm {4 – 5 kgm}

6) Install the injector wiring harness.

★ Tighten the terminal nuts at the top of the

injector in turn.

3

Nut:

2 ± 0.2 Nm {0.2 ± 0.02 kgm}

3

Rocker arm assembly mounting bolt:

93 – 103 Nm {9.5 – 10.5 kgm}

★ Adjust the valve clearance. For details, see

ADJUSTING VALVE CLEARANCE.

3

Cylinder head cover mounting bolt:

29.4 – 34.3 Nm {3.0 – 3.5 kgm}

MEASURING BLOW-BY PRES-

SURE

1.

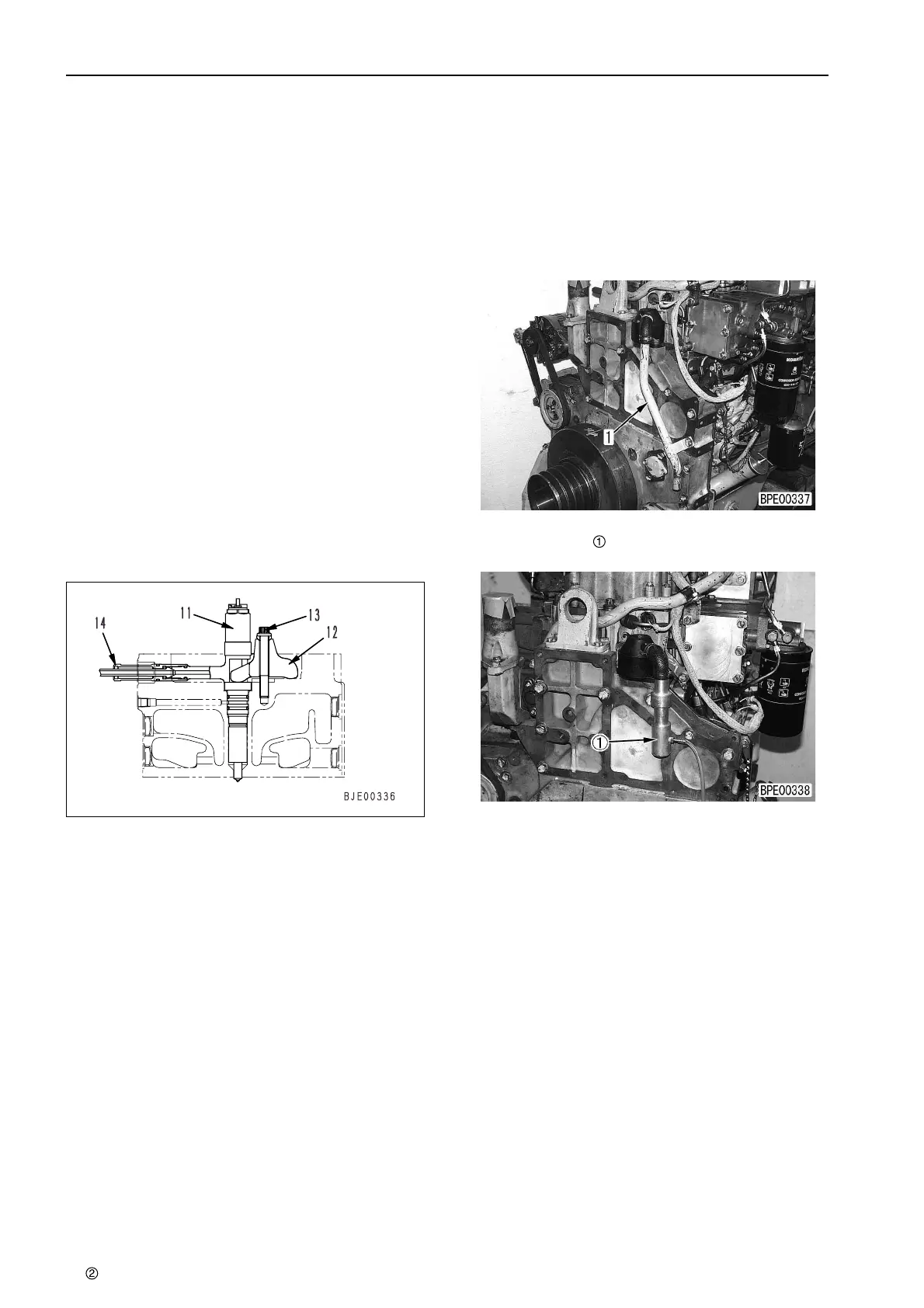

Remove blow-by tube (1).

★ For the type where a hose is installed to the

tip of the blow-by tube, the measurement

can be made at the tip of the hose, so there

is no need to remove the blow-by tube.

2.

Install nozzle of pressure test kit

A

, then con-

nect to the pressure test kit.

3.

Measure the blow-by pressure when the engine

is running at rated horsepower.

★ When measuring with the engine mounted

on the machine, measure according to the

conditions given in the shop manual for the

machine.

4.

After completing the measurement, remove the

measurement equipment and set to the original

condition.

Loading...

Loading...