PERIODIC SERVICE84

A Do not permit dirt or trash to get into the fuel system.

A Be careful not to let the fuel tank become empty,

otherwise air will enter the fuel system, necessitating

bleeding before next engine start.

A Be careful not to spill during refueling. If should spill,

wipe it off at once, or it may cause a fire.

A To prevent condensation (water) accumulation in the

fuel tank, fill the tank before parking overnight.

A No.2-D is a distillate fuel of lower volatility for engines

in industrial and heavy mobile service.

(SAE J313 JUN87)

A Grade of Diesel Fuel Oil According to ASTM D975

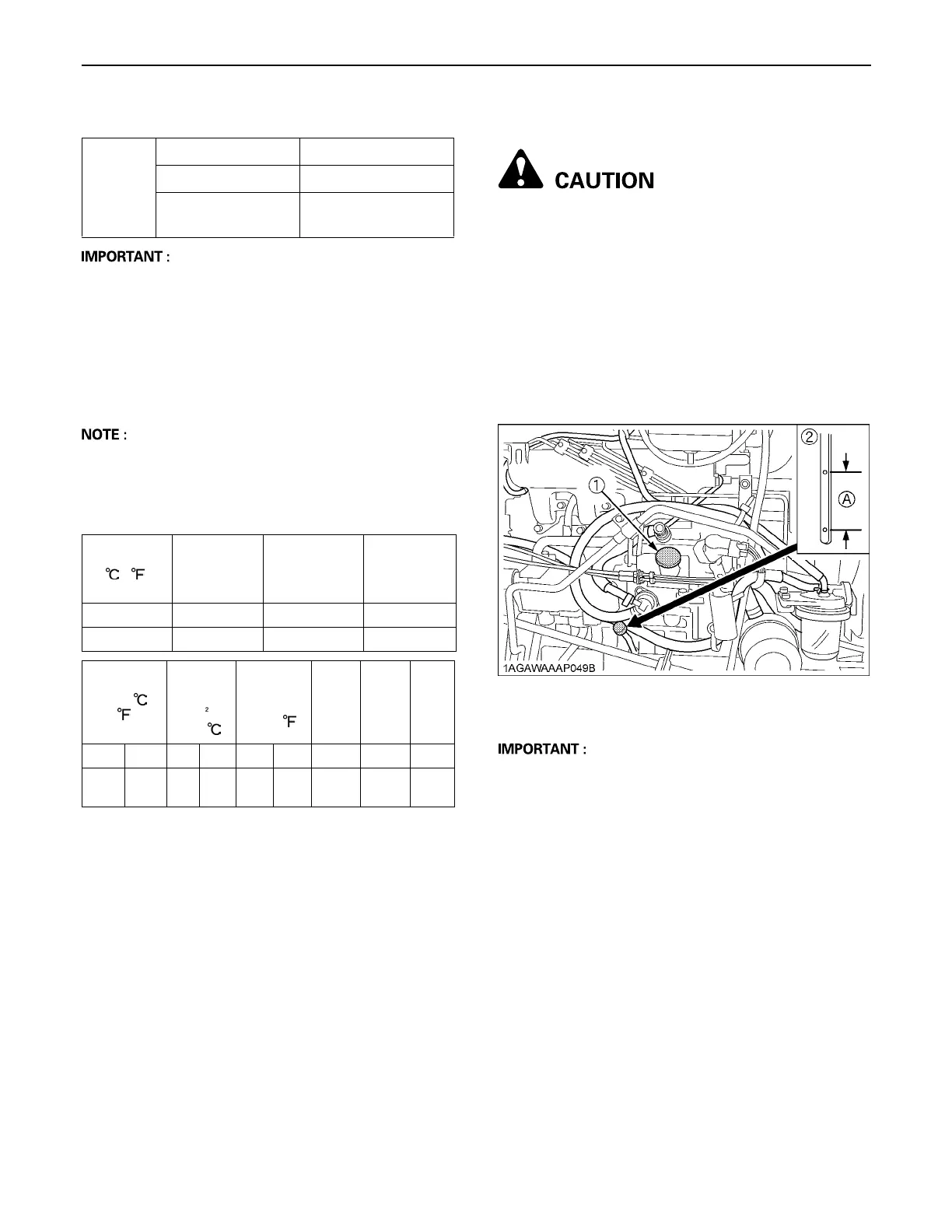

BChecking Engine Oil Level

To avoid personal injury:

A Be sure to stop the engine before checking the

oil level.

1. Park the machine on a flat surface.

2. Check engine oil before starting the engine or 5

minutes or more after the engine has stopped.

3. To check the oil level, draw out the dipstick, wipe it

clean, replace it, and draw it out again. Check to see

that the oil level lies between the two notches.

If the level is too low, add new oil to the prescribed

level at the oil inlet.

(See "LUBRICANTS" in "MAINTENANCE" section.)

A When using an oil of different maker or viscosity from

the previous one, remove all of the old oil.

Never mix two different types of oil.

A If oil level is low, do not run engine.

Fuel tank

capacity

L3240, L3540 44L (11.6 U.S.gals.)

L3940, L4240 50 L (13.2 U.S.gals.)

L4740, L5040,

L5240, L5740

54 L (14.3 U.S.gals.)

Flash Point,

()

Water and

Sediment,

volume

%

Carbon

Residue on,

10 percent

Residuum, %

Ash, weight

%

Min Max Max Max

52 (125) 0.05 0.35 0.01

Distillation

Tempera-

tures,

()

90% Point

Viscosity

Kinematic

cSt or

mm /s

at 40

Viscosity

Saybolt,

SUS

at 100

Sulfur

weight

%

Cop-

per

Strip

Corro-

sion

Ce-

tane

Num-

ber

Min Max Min Max Min Max Max Max Min

282

(540)

338

(640)

1.9 4.1 32.6 40.1 0.50 No.3 40

(1) Oil inlet

(2) Dipstick

(A) Oil level is acceptable within this range.

Loading...

Loading...