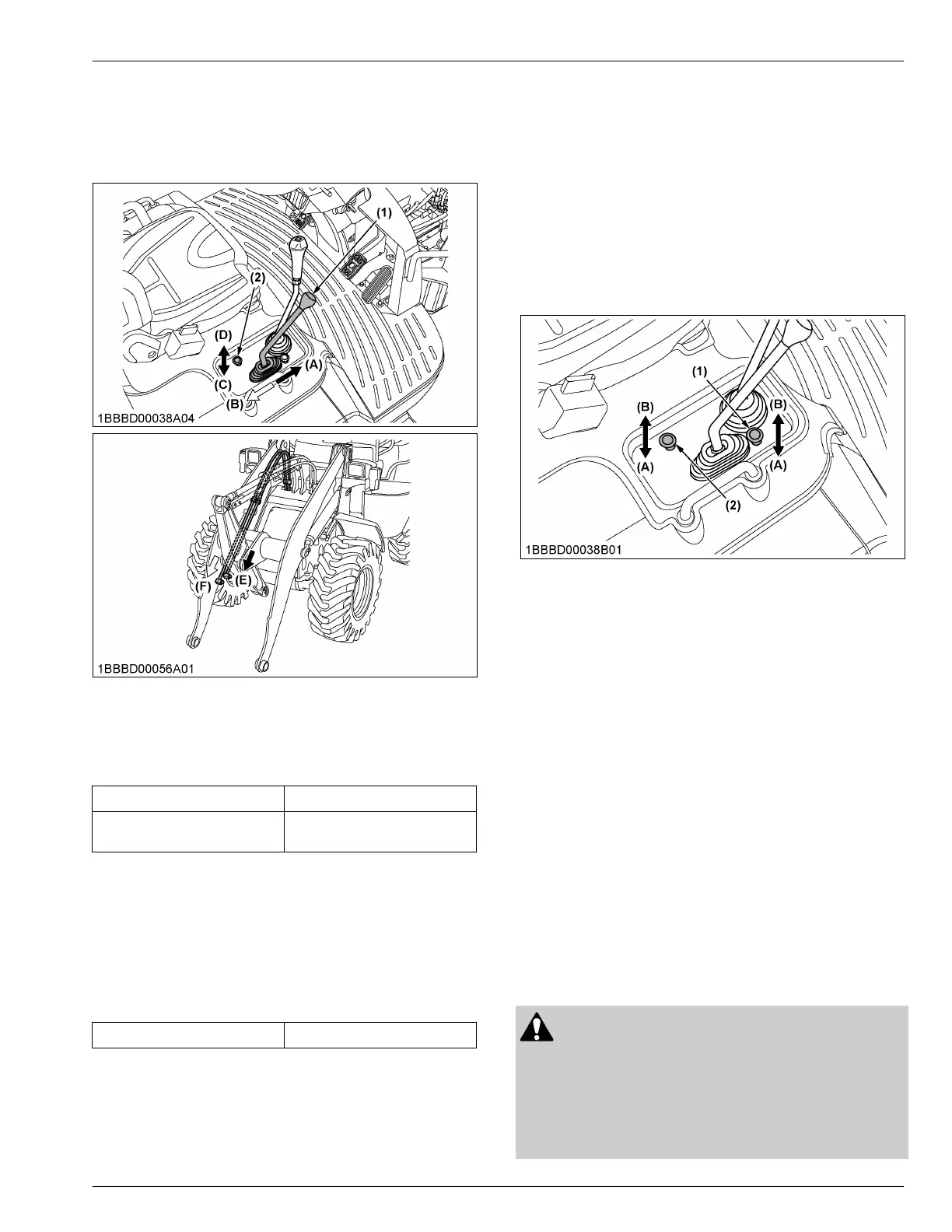

• Pulling

the auxiliary-port-lever (B) sends oil to the

pipe-B (F).

• Pressing the auxiliary-port-lever-lock-knob fully to

the lock position (C), you can hold the position of

auxiliary-port-lever.

(1) Auxiliary port lever

(2)

Auxiliary port lever lock knob

(3) Pipe-1

(4) Pipe-2

(A) Push

(B) Pull

(C) Lock

(D) Unlock

(E) Oil to pipe-1

(F) Oil to pipe-2

Max. flow volume (theoretical) 42.1 L/min.

Max. pressure

18.6 MPa

(190 kgf/cm

2

)

IMPORTANT :

• When

you do not use the auxiliary port for a

long period, dirt particles can settle in the lower

part of the auxiliary-port-lines.

When you remove the plugs on the auxiliary-

port-lines to connect attachments, drain the

following amount of oil per side before

connecting.

Oil Approx. 0.1 L

RELEASING THE PRESSURE

TRAPPED IN THE HYDRAULIC

SYSTEM

1. Lower the attachments to the ground and push the

control-lever-lock-knob and auxiliary-port-lever-lock-

knob to lock.

2. Turn the starter key to the [STOP] position and shut

off the engine.

3. Pull the control-lever-lock-knob and auxiliary-port-

lever-lock-knob to unlock.

(1) Control lever lock knob

(2) Auxiliary port lever lock knob

(A) Lock

(B) Unlock

4. Move

the control lever to release the pressure in

the hydraulic system.

MULTI-COUPLER TO ATTACH

THE FRONT A

TTACHMENT

1. Mechanical multi-coupler

This machine utilizes a mechanical multi-coupler for

easy

connection and disconnection of various

attachments.

By replacing the front attachments, you can use this

machine in agriculture, raising stock, landscaping,

gardening, and snow removal as well as general civil

engineering and construction work.

1.1 Attaching the front attachments to the

mechanical multi-coupler

Attach the front attachments to the mechanical multi-

coupler as the procedure in this section.

WARNING

T

o avoid personal injury or death:

• After carrying out the attaching procedures of

front attachments, make sure that the front

attachment is securely attached to the

mechanical multi-coupler, or the front

attachment may be detached.

RELEASING THE PRESSURE TRAPPED IN THE HYDRAULIC SYSTEM

OPERATION OF THE MACHINE