1. T

o slow charge the battery, connect the positive

terminal of battery to the positive terminal of

charger and the negative to the negative, then

recharge in the standard fashion.

A boost charge is only for emergencies. It will

partially charge the battery at a high rate and in a

short time. When using a boost-charged battery, it is

necessary to recharge the battery as early as

possible.

Failure to recharge the battery will shorten the

service life of battery.

The battery is charged if the indicator display turns

green from black.

When exchanging an old battery for a new one, a

battery of equal specification.

Battery type Volts (V) Capacity

GP24 (90D26L) 12 52 (at 5H.R (A.H))

Battery type

Reserve ca-

pacity (min)

Cold crank-

ing amps

Normal

charging rate

(A)

GP24

(90D26L)

125 680 6.5

2.2 Storing the battery

When storing the machine for long periods of time,

follow the procedure in this section.

1.

Remove the battery from machine.

2. Adjust the electrolyte to the proper level.

3. Store the batter in a dry place out of direct sunlight.

The battery self-discharges while it is stored. Recharge

it

once every 3 months in hot seasons and once every

6 months in cold seasons.

SERVICE EVERY 200 HOURS

Perform inspection and servicing for every 50 hours of

operation at the same time.

1. Checking the fan belt tension

WARNING

T

o avoid personal injury or death:

• Only check the fan belt with the engine off and

the starter key removed.

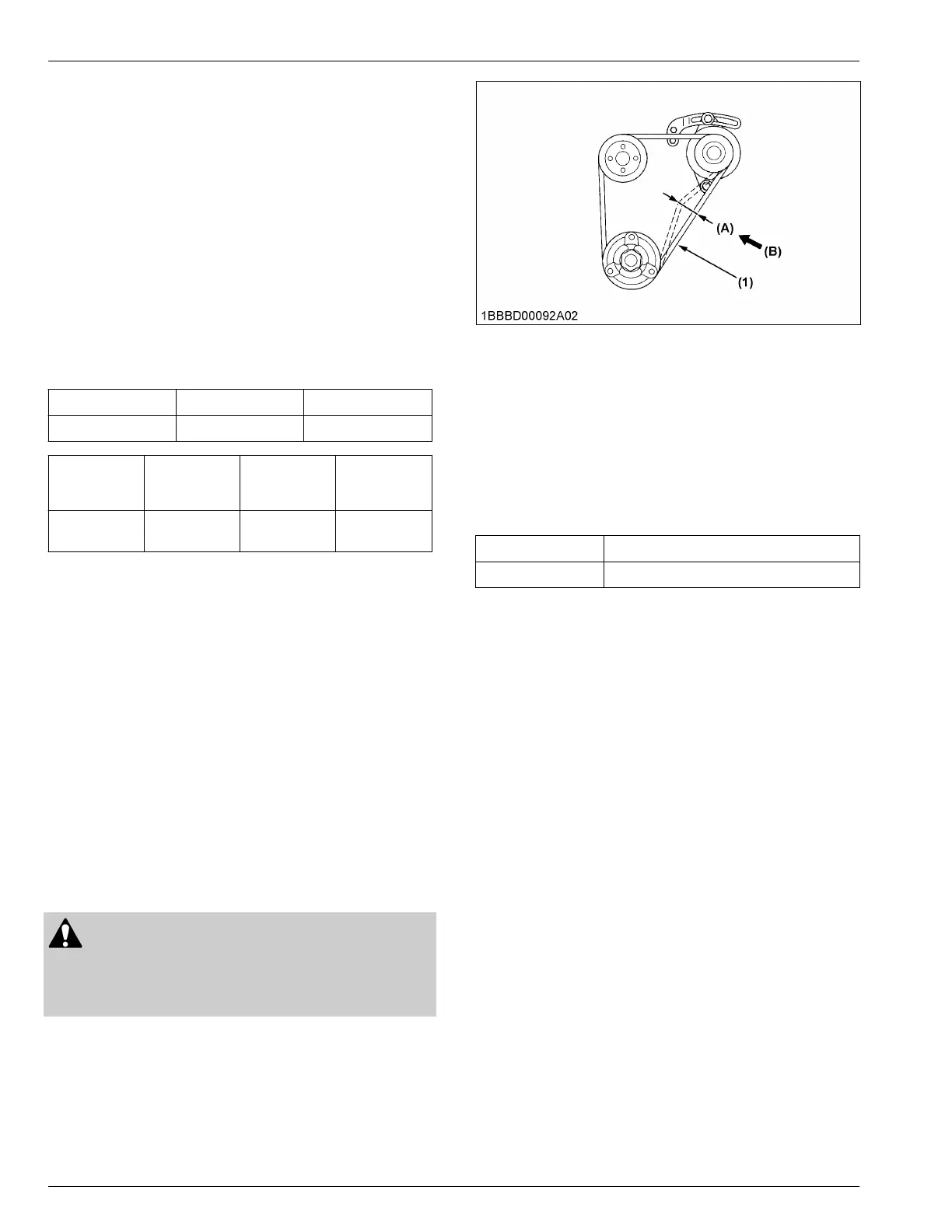

1. Check and adjust the tension of V-belt.

(SeeChecking

and adjusting the V-belt tension on

page 76)

(1) V-belt (A) Approx. 7 mm to 9 mm

(B)

Approx. 6 kg to 7 kg

1.1 Checking and adjusting the V-belt

tension

1. Press

the fan belt in the middle with a fingertip by a

force as follows.

The tension of fan belt is proper if the fan belt

deflects the following length.

Fingertip force About 6 kg to 7 kg

Fan belt tension About 7 mm to 9 mm

2. If

the tension of fan belt is improper, adjust the

tension of fan belt by loosening the bolts and

shifting the alternator in the direction shown by the

arrow (A) in the following figure.

3. Check the pulleys and the V-belts for damage and

wear.

Carefully check to see if the V-belts fit snugly into

the V-belt grooves.

PERIODIC SERVICE SERVICE EVERY 50 HOURS