PERIODIC SERVICE62

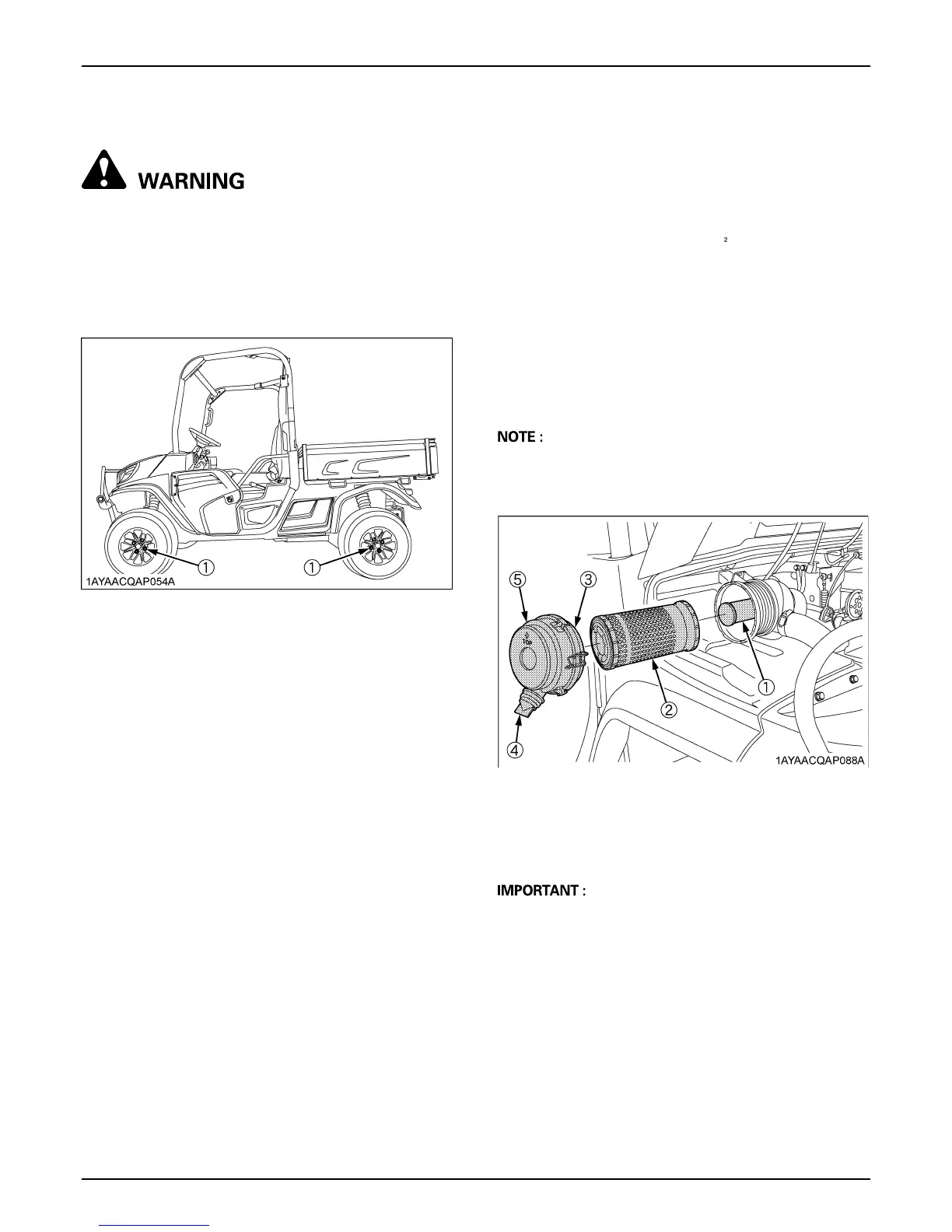

BChecking Wheel Fastener Torque

To avoid serious injury:

A Never operate vehicle with a loose wheel bolts.

A Any time bolts are loosened, retighten to the

specified torque.

A Check all bolts frequently and keep them tight.

Check wheel bolts regularly especially when new. If they

are loose, tighten them as follows.

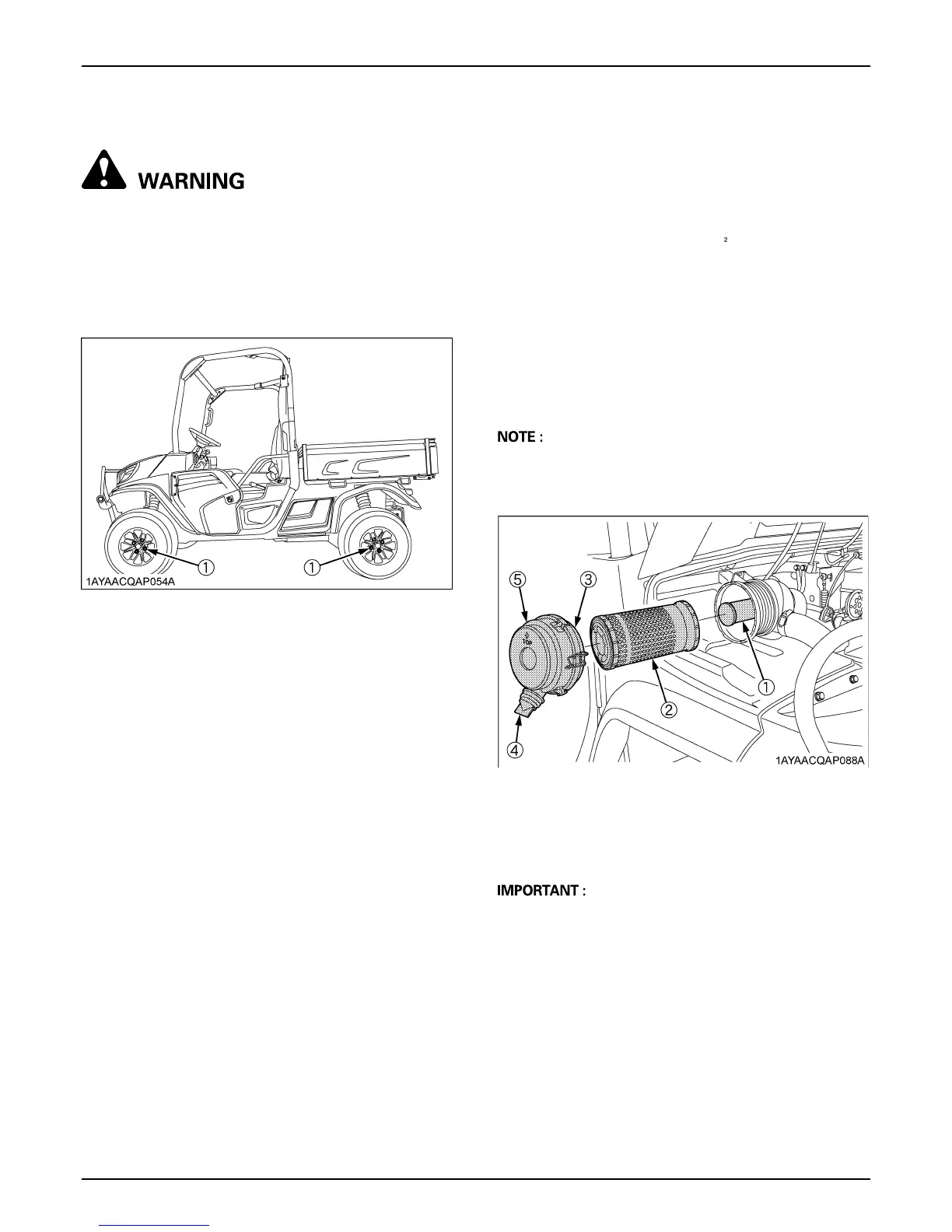

BCleaning Air Cleaner Primary Element

1. Remove the air cleaner cover and primary element.

2. Clean the primary element:

(1) When dry dust adheres to the element, blow

compressed air from the inside, turning the

element. Pressure of compressed air must be

under 205 kPa (2.1 kgf/cm , 30 psi).

(2) When carbon or oil adheres to the element,

replace the element with new one even if it has

not been used for 1 year.

Do not blow material onto yourself. Wear

appropriate protective gear when cleaning

element.

3. Replace the primary element:

Once yearly or after every sixth cleaning, whichever

comes first.

A Check to see if the evacuator valve is blocked with

dust.

A Check the rubber seal. Replace if damaged.

A The air cleaner uses a dry element, never apply oil.

A Do not run the engine with filter element removed.

A Be sure to refit the cover with the arrow (on the rear of

cover) upright. If the cover is improperly fitted,

evacuator valve will not function and dust will adhere

to the element.

A Do not touch the secondary element except in cases

where replacing is required.

C Evacuator Valve

Open the evacuator valve once a week under ordinary

conditions - or daily when used in a dusty place - to get rid

of large particles of dust and dirt.

(1) Tightening torque (bolts and nuts)

Aluminum wheel: 90 to 110 N-m

(9.2 to 11.2 kgf-m) (66.4 to 81.1 lbf-ft)

Steel wheel: 108 to 130 N-m

(11.1 to 13.2 kgf-m) (79.7 to 95.8 lbf-ft)

(1) Secondary (safety) element

(2) Primary element

(3) Rubber seal

(4) Evacuator valve

(5) Cover

Loading...

Loading...