Page 44

KG/KC 024, 030, 036, 048, 060, 072, 074, 090

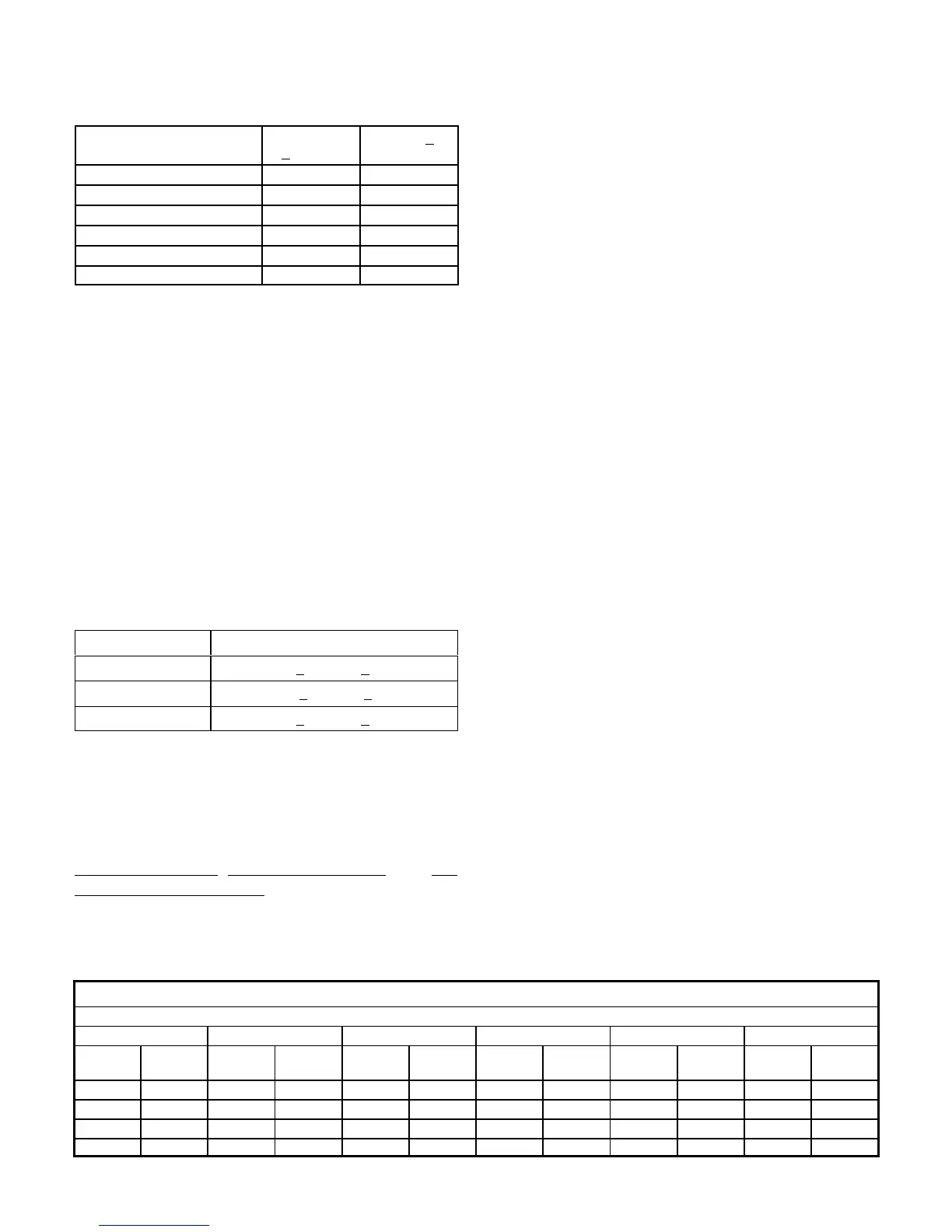

TABLE 12

KGA 060S -5 & HIGHER; KCA 060S -4 & HIGHER

NORMAL OPERATING PRESSURES

Outdoor Coil

Entering Air Temp

Discharge

+

10 psig

Suction + 5

psig

65 279 130

75 317 135

85 359 139

95 404 143

105 454 143

115 508 143

D-Charge Verification-Approach Method--Fin/Tube Coils

KGA/KCA 036-060 Units

1- Using the same thermometer, compare liquid

temperature to outdoor ambient temperature.

Approach Temperature = Liquid temperature minus

ambient temperature.

2- Approach temperature should match values in table

13. An approach temperature greater than value

shown indicates an undercharge. An approach

temperature less than value shown indicates an

overcharge.

3- Do not use the approach method if system pressures

do not match pressures in tables 7 through 12. The

approach method is not valid for grossly over or

undercharged systems.

TABLE 13

APPROACH TEMPERATURE

Unit Liquid Temp. Minus Ambient Temp.

036S 7°F + 1 (3.9°C + 0.5)

048S 11°F + 1 (6.1°C + 0.5)

060S 6°F + 1 (3.3°C + 0.5)

E-Refrigerant Charge and Check - All-Aluminum Coil

KGA/KCA 072, 090 & KGB/KCB024-074

WARNING-Do not exceed nameplate charge under

any condition.

This unit is factory charged and should require no further

adjustment. If the system requires additional refrigerant,

reclaim the charge,

evacuate the system, and add

required nameplate charge.

NOTE - System charging is not recommended below

60F (15C). In temperatures below 60F (15C), the

charge must be weighed into the system.

If weighing facilities are not available, or to check the

charge, use the following procedure:

IMPORTANT - Charge unit in standard cooling mode.

1- Make sure outdoor coil is clean. Attach gauge

manifolds and operate unit at full CFM in cooling mode

with economizer disabled until system stabilizes

(approximately five minutes). Make sure all outdoor air

dampers are closed.

2- Compare the normal operating pressures (see table

14 through 21) to the pressures obtained from the

gauges. Check unit components if there are

significant differences.

3- Measure the outdoor ambient temperature and the

suction pressure. Refer to the appropriate circuit

charging curve to determine a target liquid

temperature.

Note - Pressures are listed for sea level applications.

4- Use the same thermometer to accurately measure the

liquid temperature (in the outdoor section).

If measured liquid temperature is higher than

the target liquid temperature, add refrigerant to

the system.

If measured liquid temperature is lower than

the target liquid temperature, recover some

refrigerant from the system.

5- Add or remove charge in increments. Allow the

system to stabilize each time refrigerant is added or

removed.

6- Continue the process until measured liquid

temperature agrees with the target liquid

temperature. Do not go below the target liquid

temperature when adjusting charge. Note that

suction pressure can change as charge is adjusted.

7- Example KG/KC 090: At 95°F outdoor ambient and

a measured suction pressure of 130psig, the target

liquid temperature is 99°F. For a measured liquid

temperature of 106°F, add charge in increments

until measured liquid temperature agrees with the

target liquid temperature.

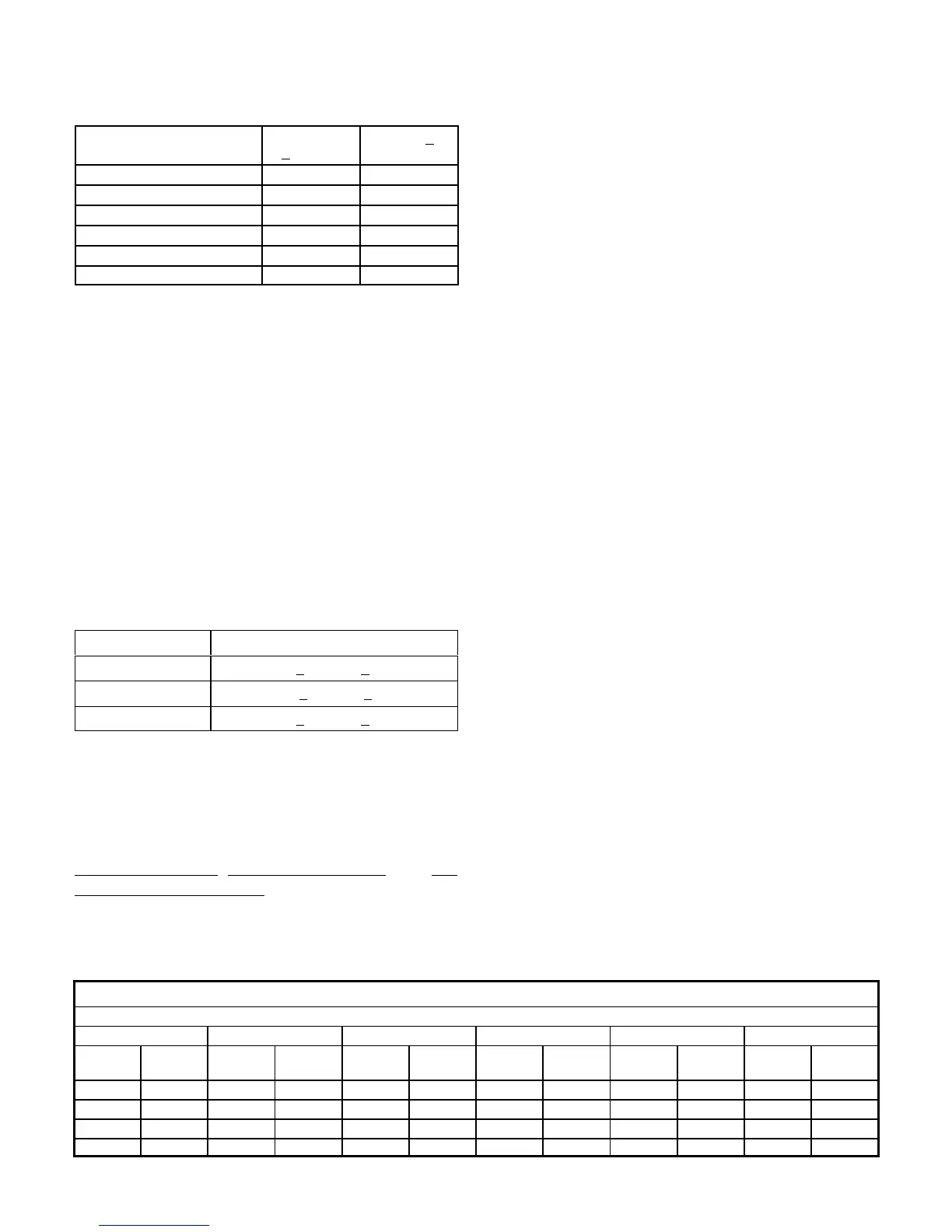

TABLE 14

KGB/KCB024 Normal Operating Pressures

Outdoor Coil Entering Air Temperature

65 °F 75 °F 85 °F 95 °F 105 °F 115 °F

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

Suct

(psig)

Disc

(psig)

118 224 119 259 121 297 121 342 122 390 124 442

125 227 127 262 129 301 130 343 131 391 134 441

141 232 144 267 149 306 151 347 153 393 154 444

159 236 164 273 168 311 171 354 173 400 176 449

Loading...

Loading...