Basics for wiring according to EMC

Requirements on the cables

6

Basic unit wiring

6.3

6.3.1

L

6.3-1

EDS82EV903-1.0-11/2002

6.3 Basics for wiring according to EMC

6.3.1 Requirements on the cables

l Only use shielded, four-core motor cable (core U, V, W, PE and overall

shield).

l Cables with a YCY copper braid have a good shielding effect, cables with

SY steel-tape armour are less suitable (high shield resistance).

l The contact ratio of the braid:

– At least 70% to 80% with overlap angle 90°

–

l Use low-capacity cables to minimise the leakage currents.

– The values depend on the cable cross-section.

l The rated voltage of the motor cable for inverter operation amounts to

Uo/U= 0.6/1 kV.

l The cables used must comply with the required approvals of the application

(e.g. UL).

The EMC safety for the temperature monitoring of the motor depends on how the

shielded connecting cables are layed.

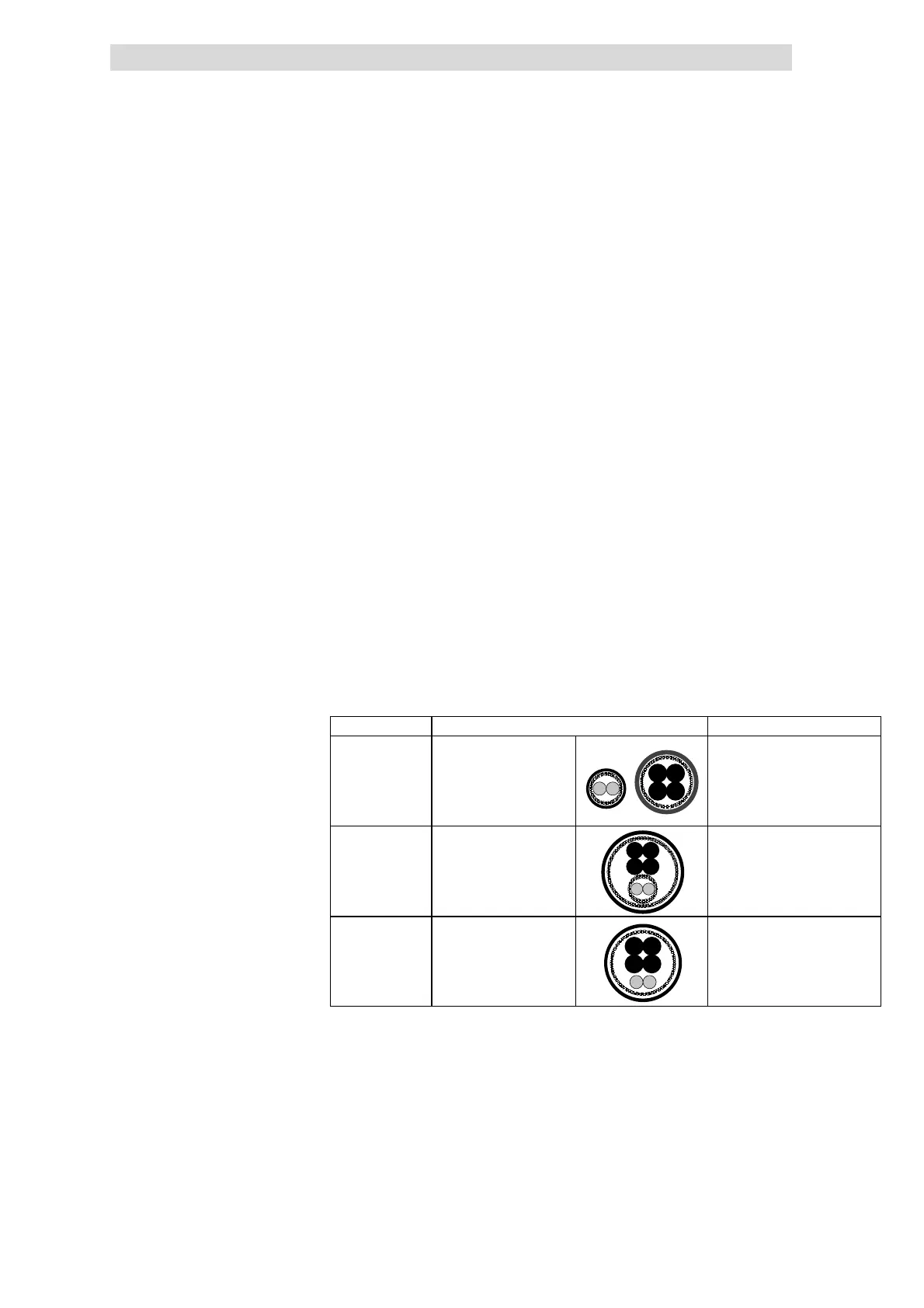

EMC safety 4 Type of laying Comment

Very good Motor cable and PTC/thermal

contact cable are layed

separately

Ideal t ype of laying with ver y low

interference injections

Use PTC/thermal contact cable as a

control cable

Medium Motor cable and PTC/t hermal

contact cable are layed

together with separate

shields

Type of laying is permitted but

show higher interference injections

Unfavorable Motor cable and PTC/thermal

contact cable are layed

together with a common

shield

High-energy interference injections

l These DC cables must be designed as the motor cable.

– Shielding

– Rated voltage

– Approval

l Being relatively short, low-capacity versions are not necessary.

Control cables must be shielded to minimise interferences.

Motor cable design

Cable design for DC supply and

brake resistor

Control cable design

Loading...

Loading...