Process controller

Setting of control characteristics

10

Function library

10.10

10.10.1

L

10.10-1

EDS82EV903-1.0-11/2002

10.10 Process controller

10.10.1 Setting of control characteristics

The process controller serves to put up control loops for controlling e.g. speed,

pressure, temperature, flow rate, humidity, level or dancer position.

The process controllerrequires asetpoint and an actualvalue(e.g.from asensor).

If setpoint and actual value are selected as analog values (potentiometer, PLC),

the controller must be equipped with an application I/O to build up a control

circuit.

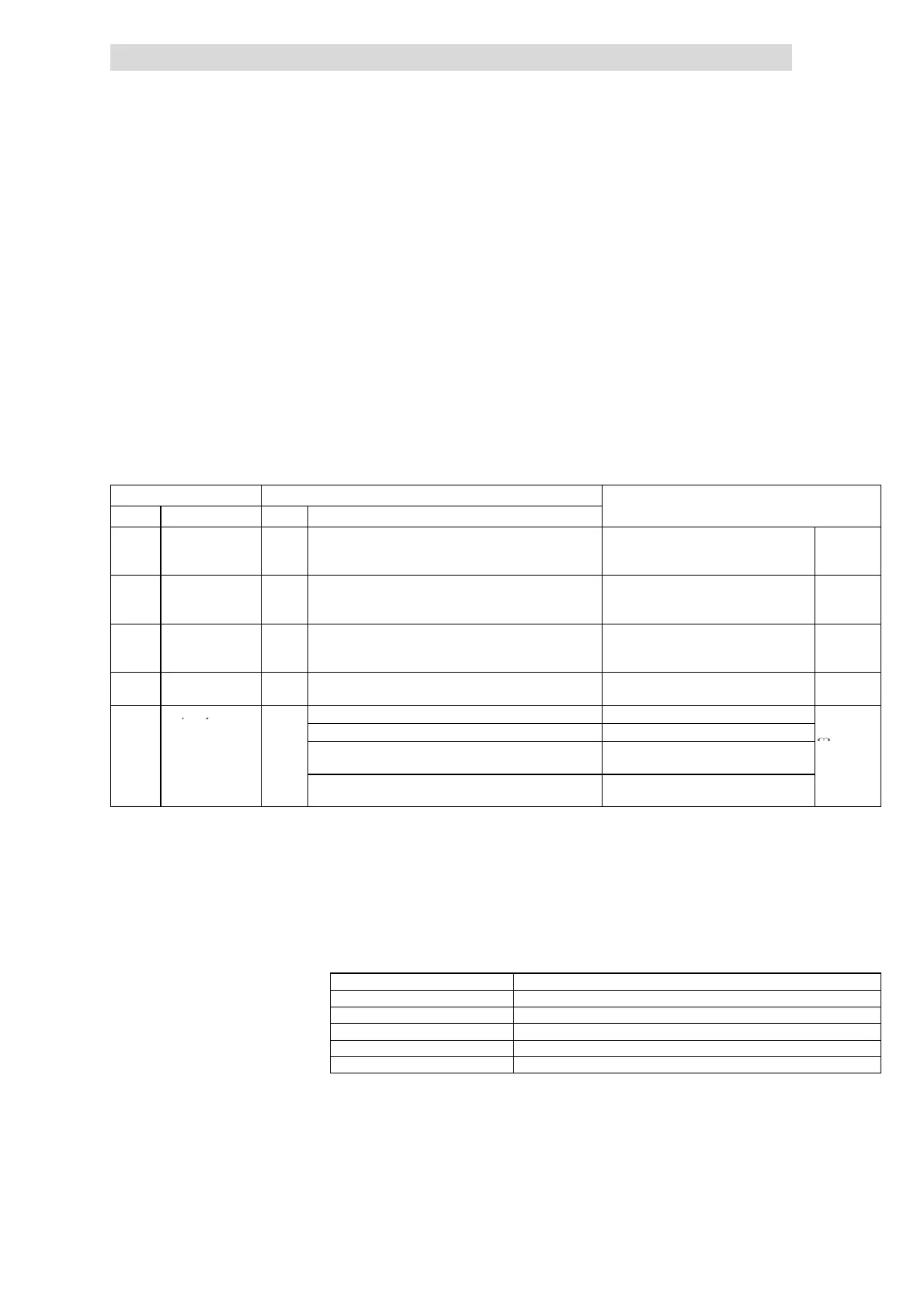

Codes for parameter setting

Code Possible settings IMPORTANT

No. Name Lenze Selection

C0070 Process controller

gain

1.00 0.00

= P component not

active

{0.01} 300.00 ^

10.10-1

C0071 Process controller

readjust me nt time

100 10 {1} 9999

= I component not

active

^

10.10-1

C0072 Differential

component of

process controller

0.0 0.0

= D component not

active

{0.1} 5.0 ^

10.10-1

C0074 Process controller

influence

0.0 0.0 {0.1 %} 100.0 ^

10.10-1

C0238 Frequency 2

0 No precontrol (only process controller) Process controller has full influence

^

v

precontrol

1 Precontrol (total setpoint + process controller) Process controller has limited influence

10.10-1

2 No precontrol (only total setpoint) Process controller has no influence (not

active)

^

10.10-5

Total setpoint (PCTRL1-SET3) = Main

setpoint + additional setpoint

1. Control features must be coarsely adjusted according to the guide values in

the following tables.

2. Fine adjustment:

– Set C0070, C0071, and C0072 so that in the event of setpoint and actual

value changes the target value can be reached quickly and with minimum

overshooting.

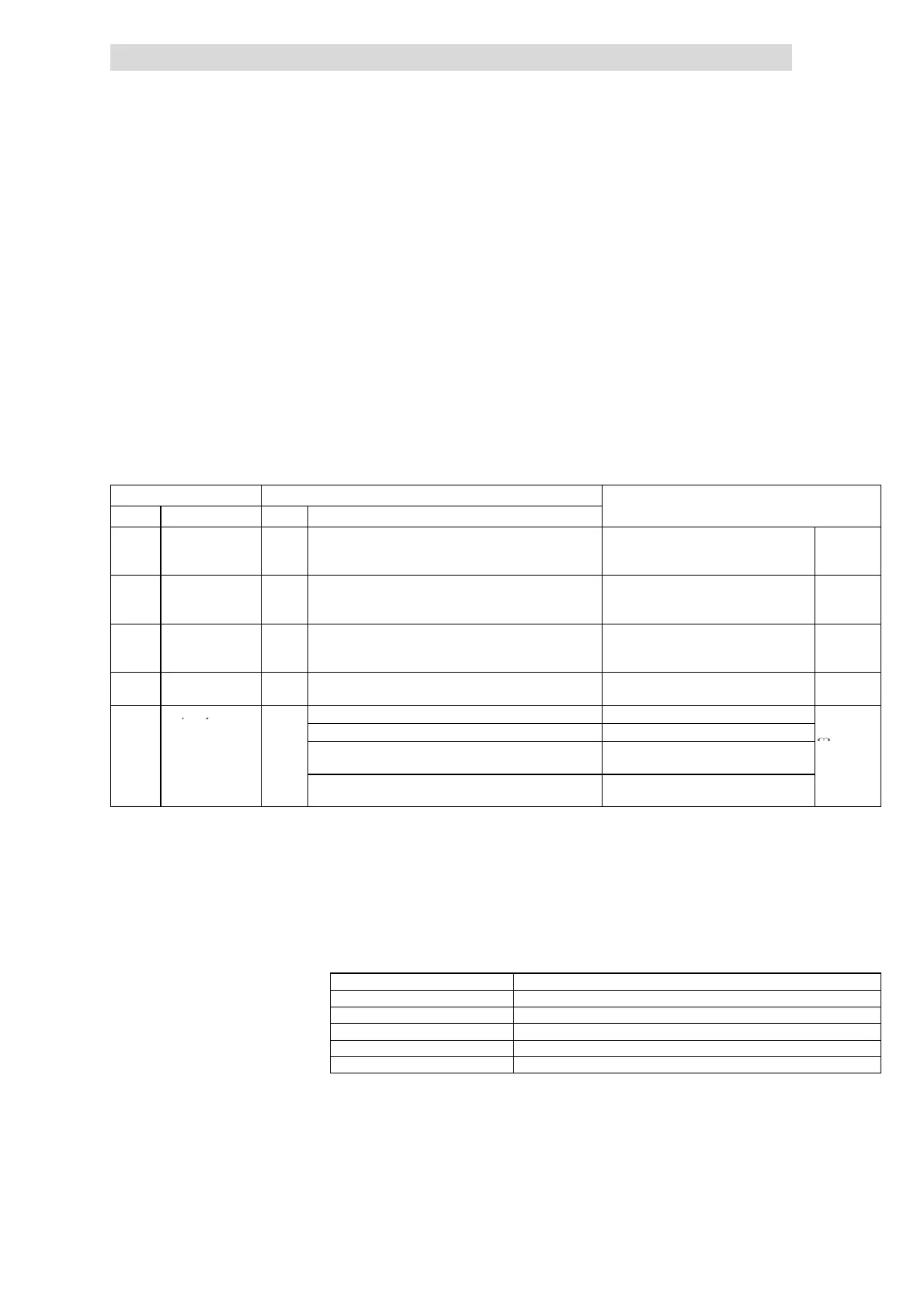

Value in C0071 Resulting readjustment time T

r

10 ... 5000 10 ms ... 5000 ms

5000 ... 6000 5 s ... 10 s

6000 ... 7000 10 s ... 100 s

7000 ... 8000 100 s ... 1000 s

8000 ... 9998 1000 s ... 9998 s

Description

Adjustment

Scaling C0071

Loading...

Loading...