National Crane 1-21-2019 Control # 104-07 4-23

1400A SERVICE MANUAL BOOM MAINTENANCE

Nut configuration (see Figure 9) will be First Nut

(ADJUSTMENT) and Second Nut (TORQUED).

NOTE: (OPTION 2) method used ONLY when space

constraints prevent OPTION 1 usage.

When tightening/loosening the first (adjustment) nuts on

cables, secure cable using the wrench flats at the front of the

cable ends to prevent cable twist.

After the cable adjustment procedure is completed for the

entire boom assembly. The second (torqued) nut must be

installed on all retract and extend cables.

The second nut should be hand tightened until it comes in

contact with the back of the first nut.

Hold the first (adjustment) nut stationary and a torque

wrench to tighten the second (torqued) nut against the first

(adjustment) nut to the values indicated in TORQUE

VALUES for Second Nut:

Third (positive lock) nut installation is to be placed on each of

the extend cables. The retract cables do not require the third

(positive lock) nut.

The third nut should be hand tightened until the tapped hole

for the set screw is tangent to the end face of the wrench flat.

Install set screw into Third nut and tighten.

(OPTION 2) method used ONLY when space constraints

prevent OPTION 1 usage (see Figure 9).

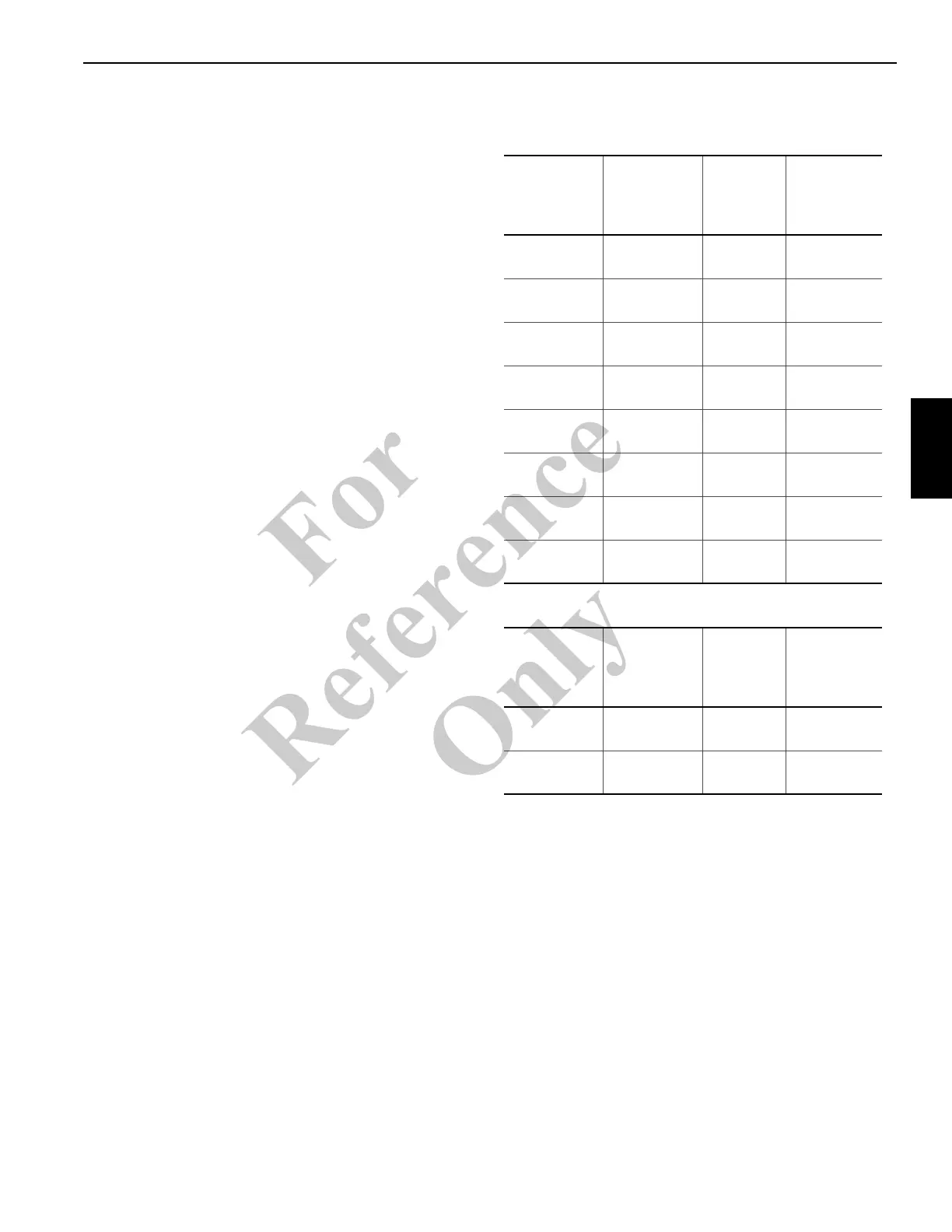

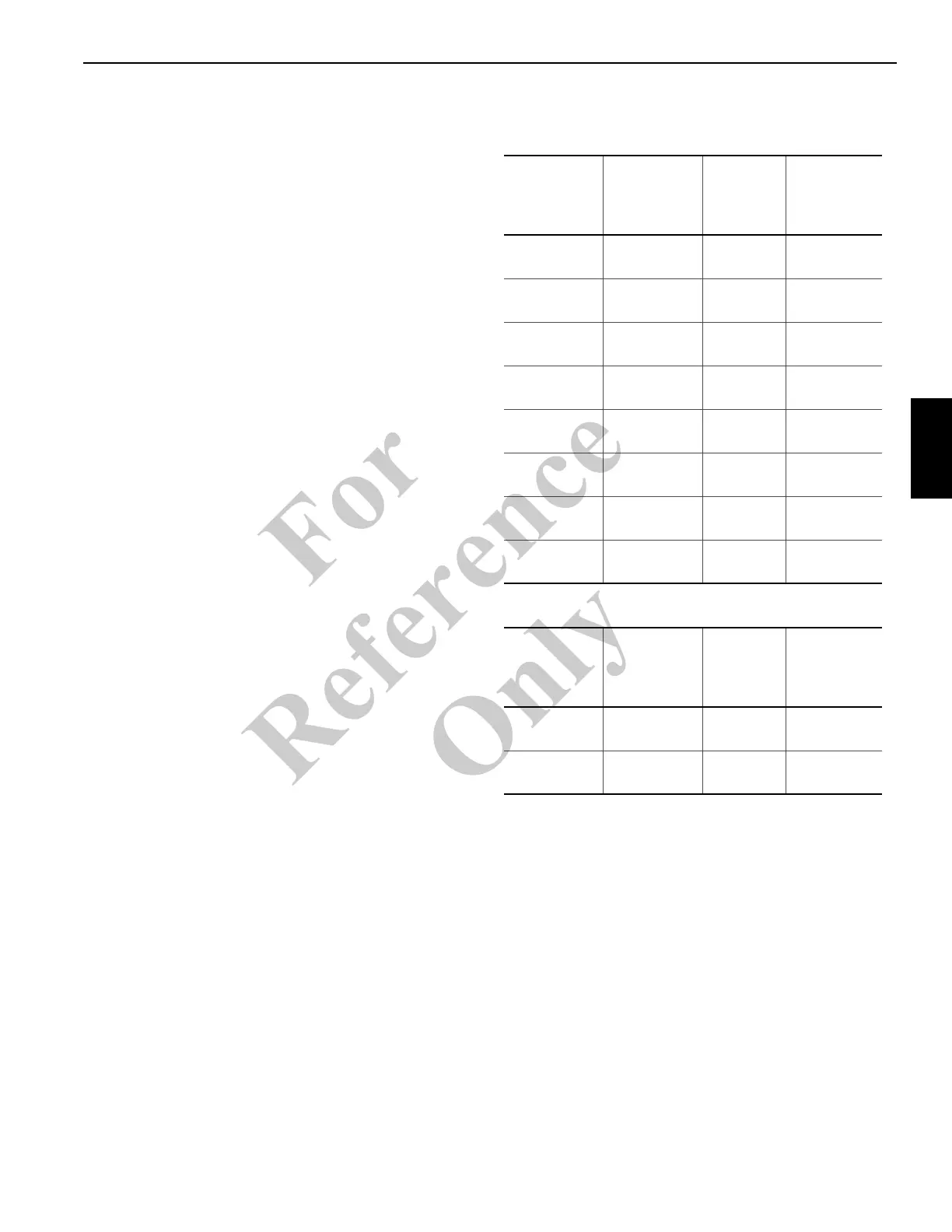

TORQUE VALUES for Second Nut:

Inch Series with Coarse Threads (UNC)

Metric Series with Coarse Threads

Cable end

Thread Size

Minimum

Nut

Strength

GRADE

Nut Type

TORQUE

ft lbf

1/2-13 SAE 2

Hex Jam

(HALF)

12

5/8-11 SAE 2

Hex Jam

(HALF)

31

3/4-10 SAE 2

Hex Jam

(HALF)

47

7/8-9 SAE 2

Hex Jam

(HALF)

63

1-8 SAE 2

Hex Jam

(HALF)

199

1 ¼-7 SAE 2

Hex Jam

(HALF)

203

1 ½-6 SAE 5

Hex Jam

(FULL)

250

1 ¾-5 ASTM B

Hex Jam

(FULL)

250

Cable end

Thread Size

Minimum

Nut

Property

Class

Nut Type

TORQUE

Nm

M16x2 5

Hex Jam

(THIN)

26

M20x2.5 5

Hex Jam

(THIN)

66

Fo

r

Reference

Only

Loading...

Loading...