Manitowoc Published 10-09-2020, Control # 259-06 5-19

MLC80A-1/MLC90A-1/MLC100A-1/MLC100-1 SERVICE/MAINTENANCE MANUAL HOISTS

To release the free fall brake, the following conditions must

be met:

• Operator seated (seat switch closed)

• Brake pedal latched down

• Free fall selector valve rotated to ON

• Free fall enable/disable key switch (on control console)

toggled to the Drum 1 and/or Drum 2 position

For specific operating instructions, see Section 3 of the

Operator Manual.

For the remaining instructions, operation applies only to the

selected drum.

When the brake pedal is latched down, flow from the free fall

pump to the brake pedals is routed to tank via the free fall

enable valve, and pressure in the circuit drops below 7 bar

(100 psi).

In the on position, the free fall selector valve allows oil flow

from the free fall brake valve to the free fall brake.

If all other conditions are met and the free fall enable key is

turned on, the control system activates the free fall brake

valve, allowing pressure to reach the free fall brake via the

free fall selector valve.

As the operator allows the brake pedal to rise, the CCS will

close the free fall enable valve (block flow to tank) and then

increase brake release pressure proportionally to the brake

pedal position via the free fall brake valve. The free fall brake

will release and the load will lower. Full brake release occurs

at 60 bar (870 psi).

Adjusting the slip setting in the main display will limit the

maximum pressure available to the brake from the free fall

pump.

When free fall is enabled, the drum control handle will

operate in the same manner as normal (non-free fall)

operation, but the operator must remember to use the free

fall brake pedal to control lowering while the control handle is

in center. Optionally, if the operator pulls back on the drum

control handle, the CCS will use this input as a proportional

control to apply the free fall brakes. See Section 3 of the

Operator Manual for free fall operating procedures.

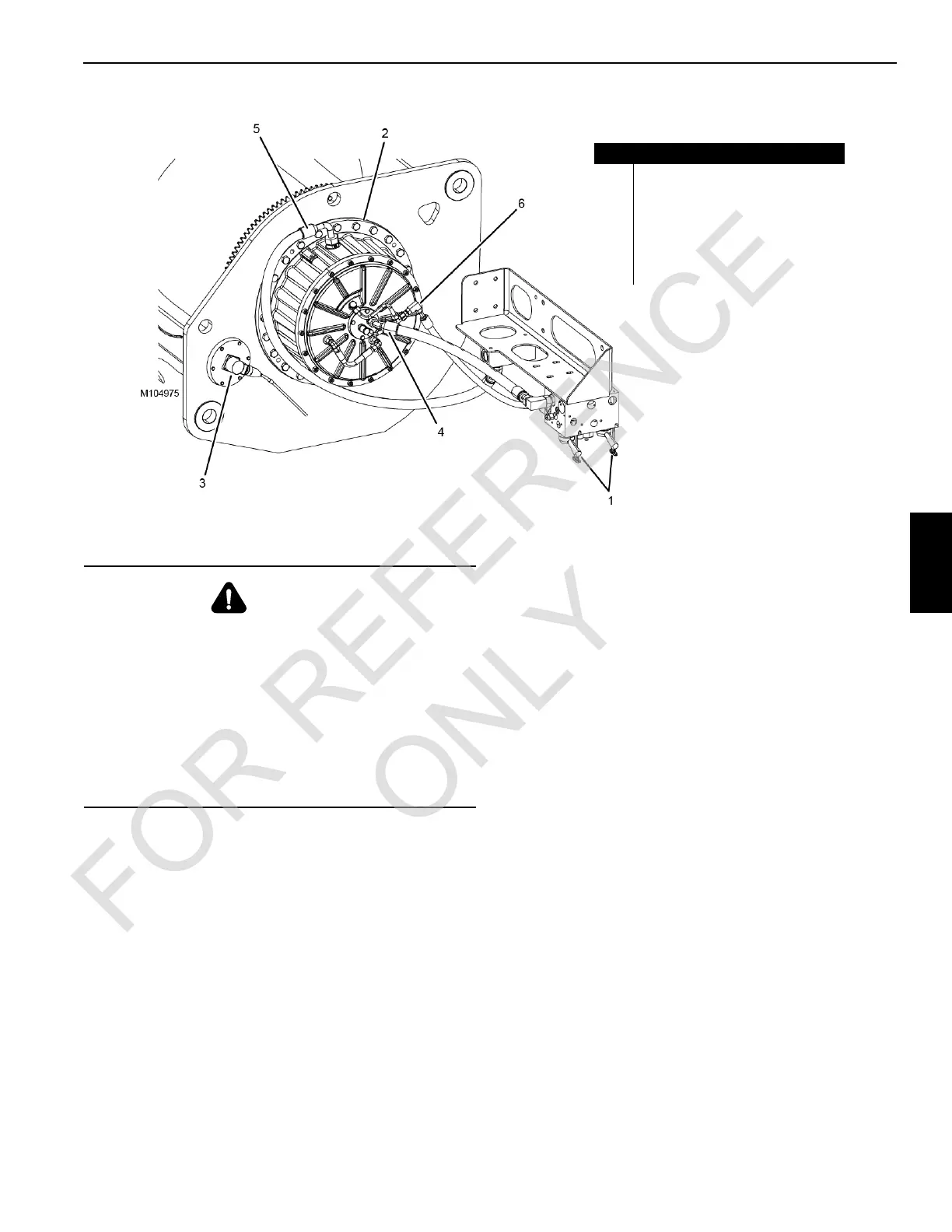

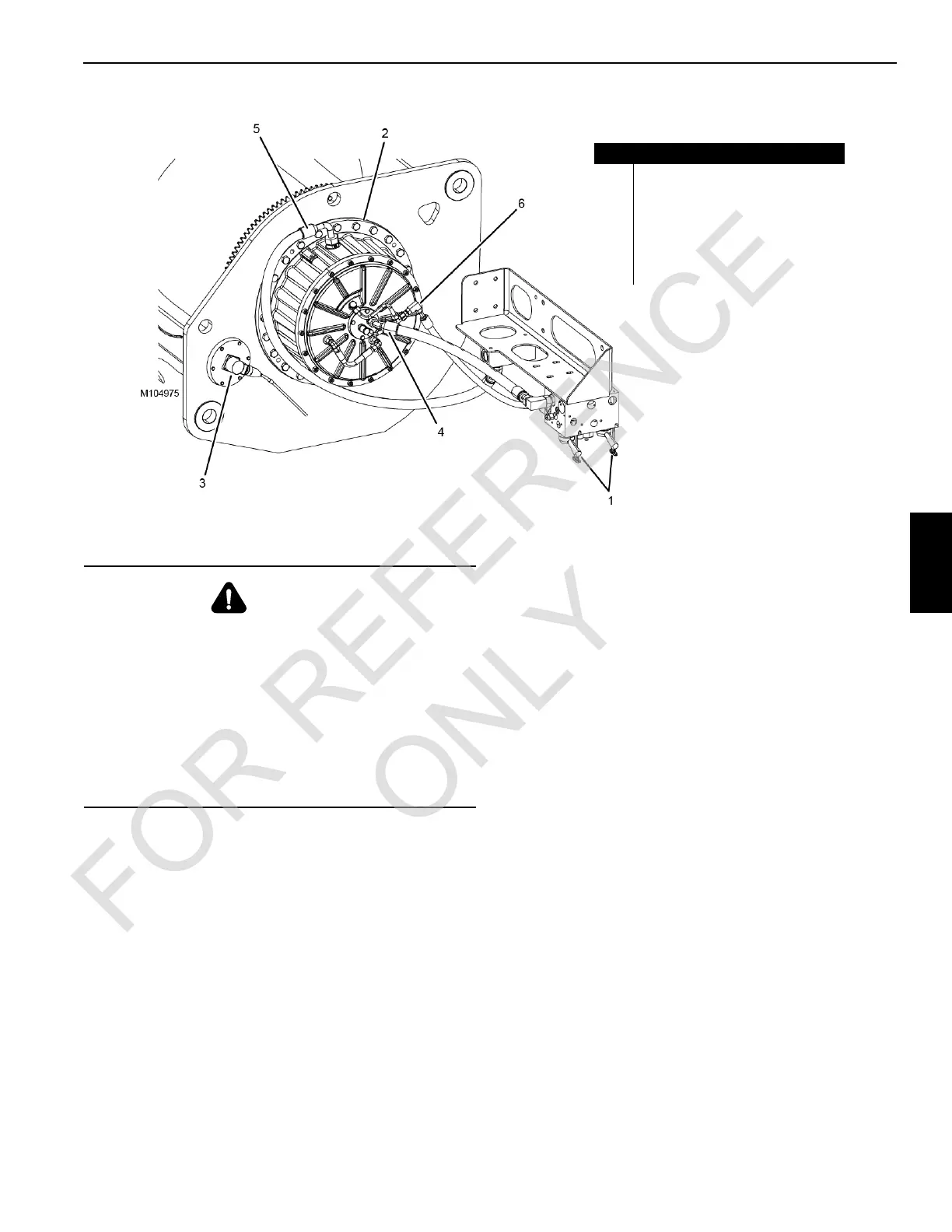

FIGURE 5-13

Item Description

1 Free Fall Selector Valves

2 Free Fall Brake (Drum 2 shown)

3 Free Fall Speed Senor

4 Cooling Flow In

5 Cooling Flow Out

6 Brake Release Pressure

WARNING

Falling Load Hazard

When the free fall mode is fully enabled, the load will fall

uncontrolled unless the brake pedal is applied.

Always be ready to apply the brake pedal so lowering

speed can be controlled.

If this is not done, the load can fall, possibly resulting in

injury or death.

To prevent the load from falling when free fall is selected

for a drum, latch down the free fall brake pedal.

Loading...

Loading...