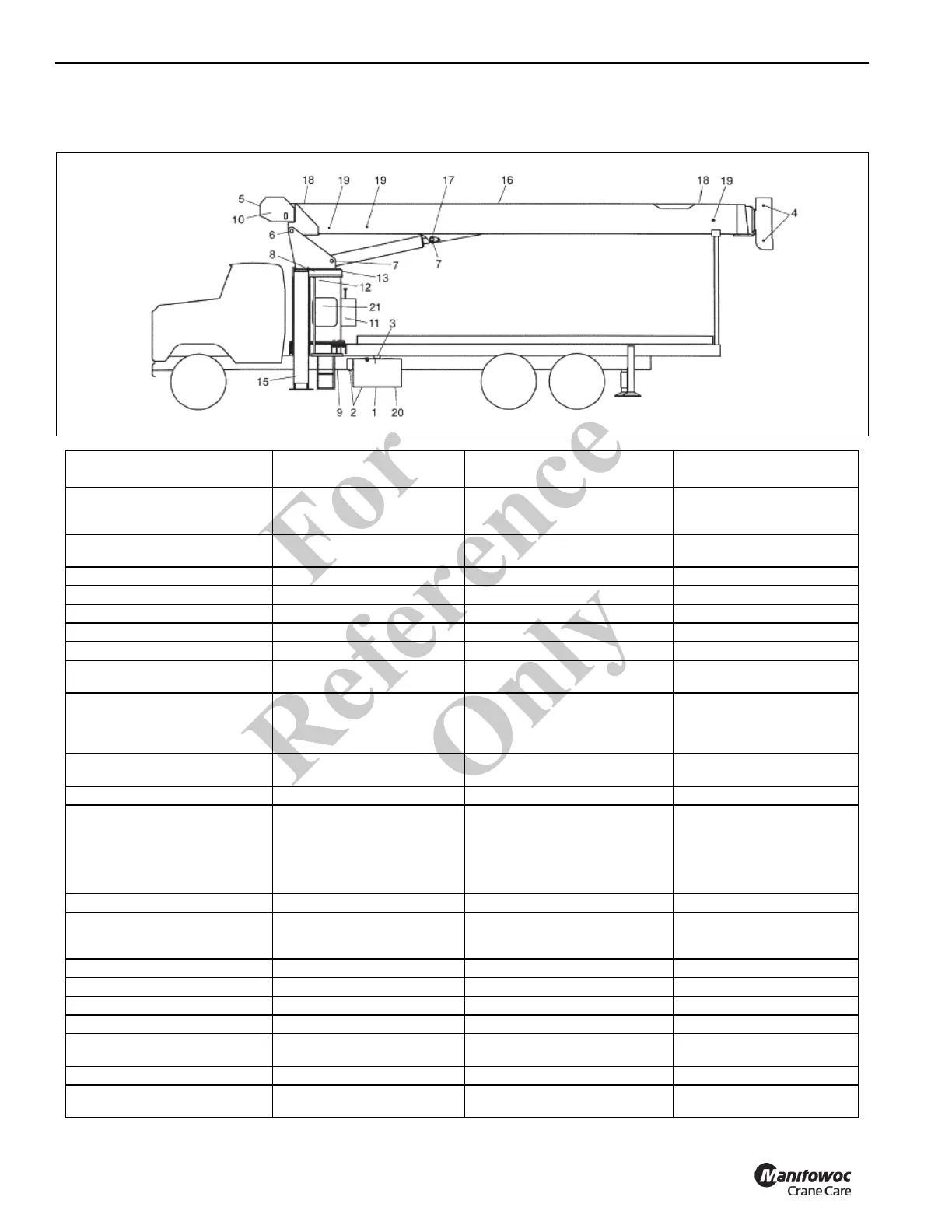

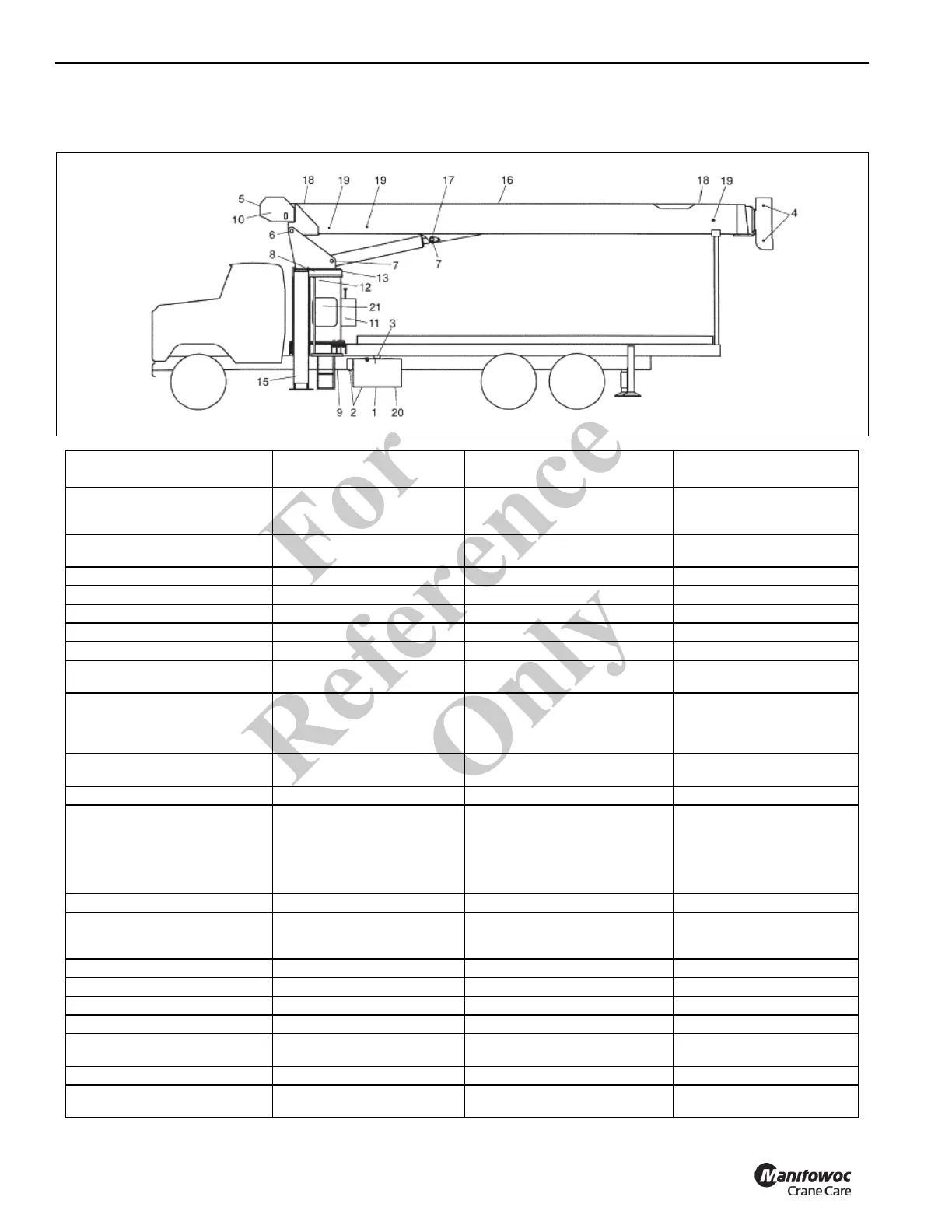

LUBRICATION 800D

4-4

Published 5-27-2018 Control # 039-06

Lubrication Chart

APPLICATION

RECOMMENDED

LUBRICANT

PROCEDURE FREQUENCY

1. Hydraulic Oil Reservoir Hydraulic Oil Check & Fill

Change (See “Hydraulic Oil

Reservoir Level” on page 4-5)

Weekly

Semi-Annually

2. Oil Filter, Magnetic Plug Change or Clean After First 40 Hours then

Quarterly

3. Reservoir Breather Clean Monthly

4. Sheave Pins/Boom-3, Jib-1 Chassis Grease Grease Gun Weekly

5. Loadline - Wire Rope Open Gear Lube Brush or Spray Semi-Annually

6. Boom Pivot Pin Chassis Grease Grease Gun Monthly

7. Lift Cylinder Pins 2 ea. Chassis Grease Grease Gun Monthly

8. Turntable Bearing Chassis Grease Grease until lubricant appears at

seal while rotating crane

Monthly

9. Pump Drive U-Joint 2 ea. or

Pump Spline Shaft (Direct Mount)

Chassis Grease

Coupling Lube Spline Lubricant

Grease Gun

Remove Pump and Apply to Shaft

or Zerk Provided on PTO Housing

Shaft

Monthly

Semi-Annually

10. Hoist Drive Refer to Hoist Manual for Oil

Recommendation on Hoist

Check & Fill

Change

Weekly

Semi-Annually

11. Control Linkage SAE-10W Oil Can Quarterly

12. Swing Drive Gearbox

Swing Gearbox, Upper Bearing

EPGL

Chassis Grease

Change

Check & Fill

Change

Grease Gun

After First 50 Operating Hours

Weekly

Semi-Annually

Monthly

13. Swing Gear Teeth Open Gear Lube Grease Gun Monthly

14. Boom Extension

Sides

Bottom

See Boom Maintenance Section

15. Outrigger Beams Low Temp Chassis Grease Brush or Roller Monthly

16. Wire Rope Cables & Boom Open Gear Lube Brush or Spray Anytime Boom is Disassembled

17. Pin Joints Penetrating Oil Spray Monthly

18. Boom Top Wear Pads See Boom Pad Lubrication

19. Sheave Bearings Chassis Grease Grease Gun with Nozzle Tip-See

Boom Maintenance Section

Semi-Annually

20. Diffuser Clean Semi-Annually with oil change

21. Optional Continuous Rot.

Swivel

Chassis Grease Grease Gun Monthly

Fo

r

Reference

Only

Loading...

Loading...