SERVICE 800D

5-42

Published 5-27-2018 Control # 039-06

11. Move to the sheave case end of the boom. Visually

determine if the wire has properly located itself onto the

sheave. If not, manipulate the wire placement through

the end of the boom and place the wire on the sheave. A

5 ft (1,50 m) long access tool (hook end) will simplify this

procedure greatly.

12. From the hoist mount end of the boom, assemble the

anti-two-block wire clamp on the extend cable anchor in

the rear of the 3rd section. Loop anti-two-block wire

around clamp and lightly tighten capscrew holding

clamp together. Keeping a slight amount of tension on

the wire at this point will keep the wire properly located

on the sheave.

13. From the sheave case end, pull the installation tool and

wire end out of the boom. The route of the anti-two-block

wire in the boom is now complete.

14. Pull wire at either end of boom to adjust length of wire on

sheave case end to properly attach and terminate wire.

15. Tighten anti-two-block wire clamp located in rear of 3rd

section.

16. Route sheave case end of anti-two-block wire around

clamp in sheave case and through holes in side plates.

Pulling on this end will tension the static length of anti-

two-block wire clamped in the 3rd. Approximately 15-25

lb (7-11 kg) will be sufficient to provide proper operation.

Tighten sheave case anti-two-block wire clamp.

17. Reassemble quick disconnect plug to anti-two-block

wire. Proper wire attachment is critical for proper anti-

two-block system operation. Consult electrical

schematic in this book for proper connector wiring

18. From hoist mount end of boom, slide strain relief/cord

grip onto wire, into approximately position inside the

boom.

19. Assemble spring and spade bolt to cord grip and

reassemble anchor components to extend cable anchor

plate on the hoist mount. Slide cord grip up anti-two-

block wire into boom to increase spring tension on

moving length of anti-two-block wire. Approximately 2 in

(50 mm) of spring extension tension should be adequate

for proper operation.

20. Visually inspect interior routing of anti-two-block wire for

excess slack in wire, inaccurate routing of wire, etc.

Correct any problems before boom operation.

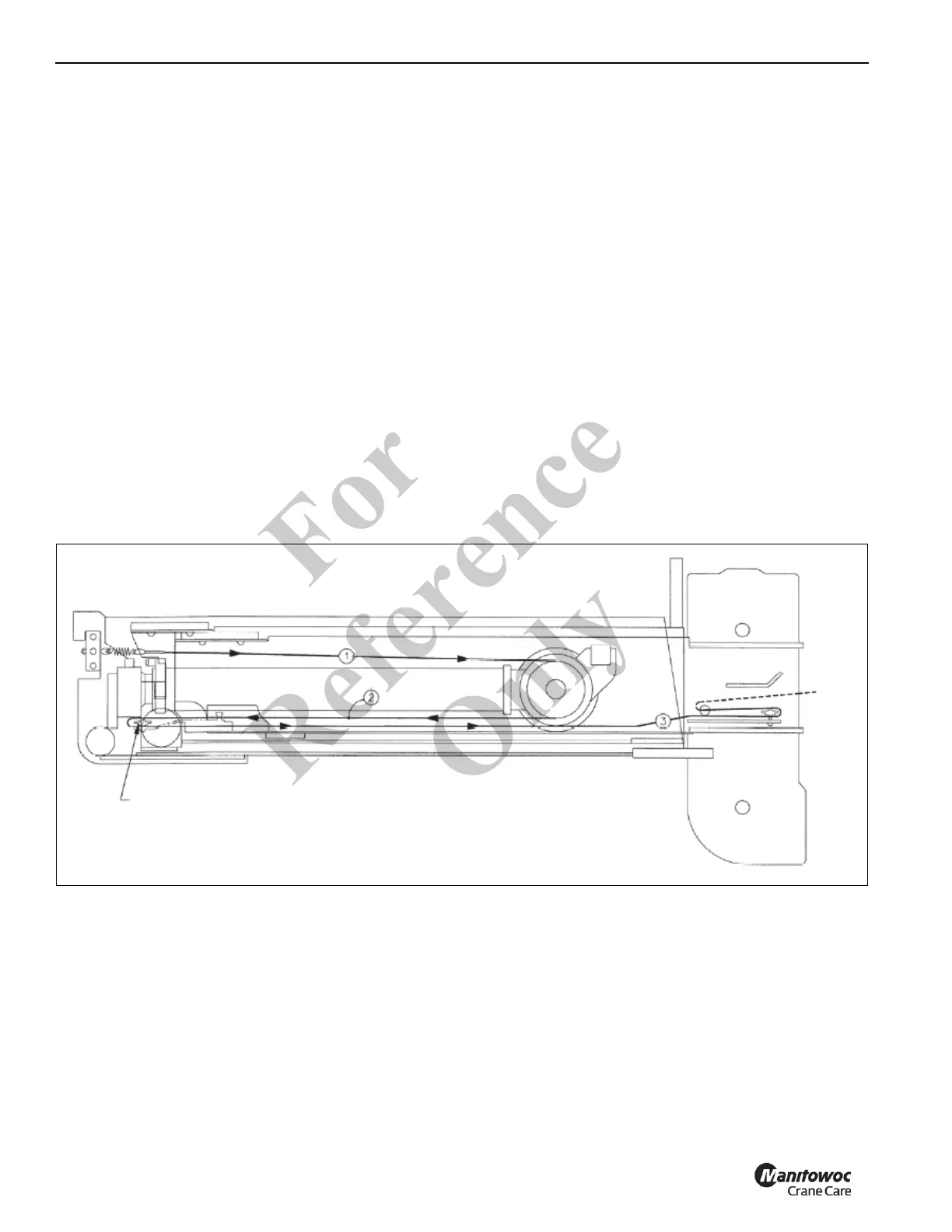

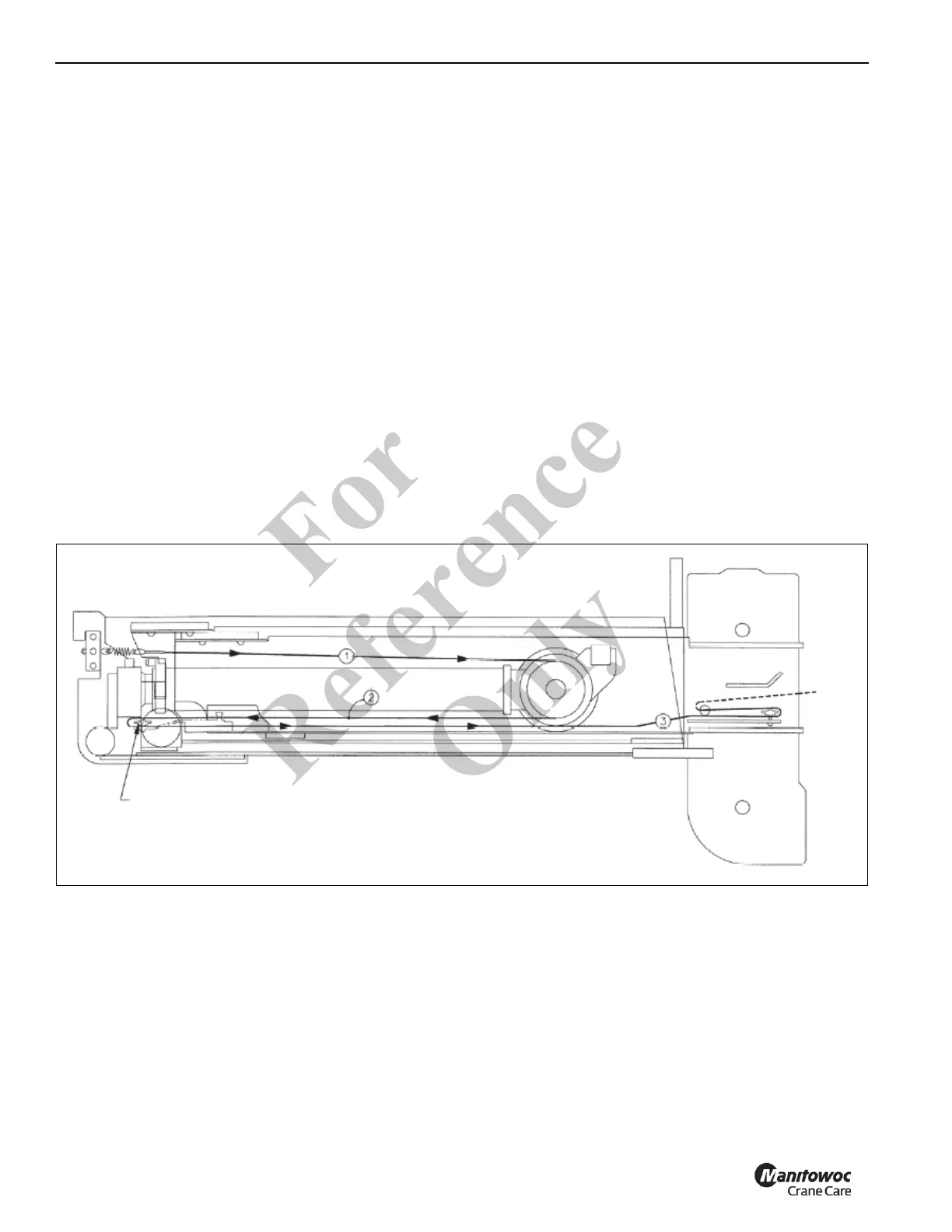

ANTI-TWO-BLOCK WIRE WITH EXTERNAL

REEL

Operation

Boom is equipped with an anti-two-block utilizing a reel on

the outside of the boom. As the boom extends, the wire pays

off of the reel and is routed through a sheave on the hoist

end of the boom. The wire is then routed through roller

guides attached at the hoist end of the 2nd and 3rd boom

sections. The wire is then anchored at both ends of the 4th

boom section. A switch at the sheave case on the 4th section

controls switching of the signal. Three and four section

booms differ only in number of roller guides.

Maintenance

In the event of a break in continuity of the anti-two-block wire,

the hydraulic portion of the system will be disabled and make

certain crane functions inoperative. Before replacement of

the wire, check for continuity loss at the anti-two-block

switch, connector damage or corrosion, and overall system

condition. Due to the environmental exposure of the system,

CABLE ANCHOR

ATB CORD ROUTING

9394

Fo

r

Reference

Only

Loading...

Loading...