24

ENGLISH

− thicknesser bed spindles;

− height-setting mechanism of cut-

terblock guard extrusion.

4. Apply a light coat of anti-seize com-

pound to infeed table, outfeed table

and thicknesser bed.

7.5 Transporting the Machine

A

Caution!

To carry the machine two persons are

required.

Do not carry the machine holding it at

the infeed and outfeed tables, these

are not designed to bear the weight of

the machine.

1. Remove jointer fence.

2. Remove outfeed table.

3. Lower cutterblock guard extrusion

fully and push extrusion all the way

in.

4. Set thicknesser bed to about half the

thicknessing height.

5. Put two roofing battens or 2 x 4's

through the machine and lift it with

the battens.

7.6 Machine Storage

A

Danger!

Store machine in such manner that

− it cannot be used or tampered

with by unauthorized persons,

and

− that nobody can get hurt while

the machine is turned off.

A

Caution!

Do not store machine unprotected

outdoors or in damp environment.

7.7 Maintenance

The checks and procedures described in

this section are an aid to safety! Should

there be faults evident on any of the

mentioned components, the machine

must not be used until these faults have

been remedied in a workmanlike man-

ner.

A

Danger!

Repairs to electric tools must be car-

ried out by qualified electricians only!

Electric tools in need of repair can be

sent to the service centre of your coun-

try. Refer to spare parts list for address.

Please attach a description of the fault to

the electric tool.

The machine's packaging materials are

100 % recyclable.

Worn out machines and accessories

contain considerable amounts of valua-

ble raw and plastic materials, which can

be recycled.

These instructions are printed on paper

produced with elemental chlorine-free

bleaching process.

A

Danger!

Prior to any servicing:

− Switch Off.

− Unplug power cable.

− Wait for cutterblock to come to a

complete stop.

Check to see that all safety devices are

operational after any servicing.

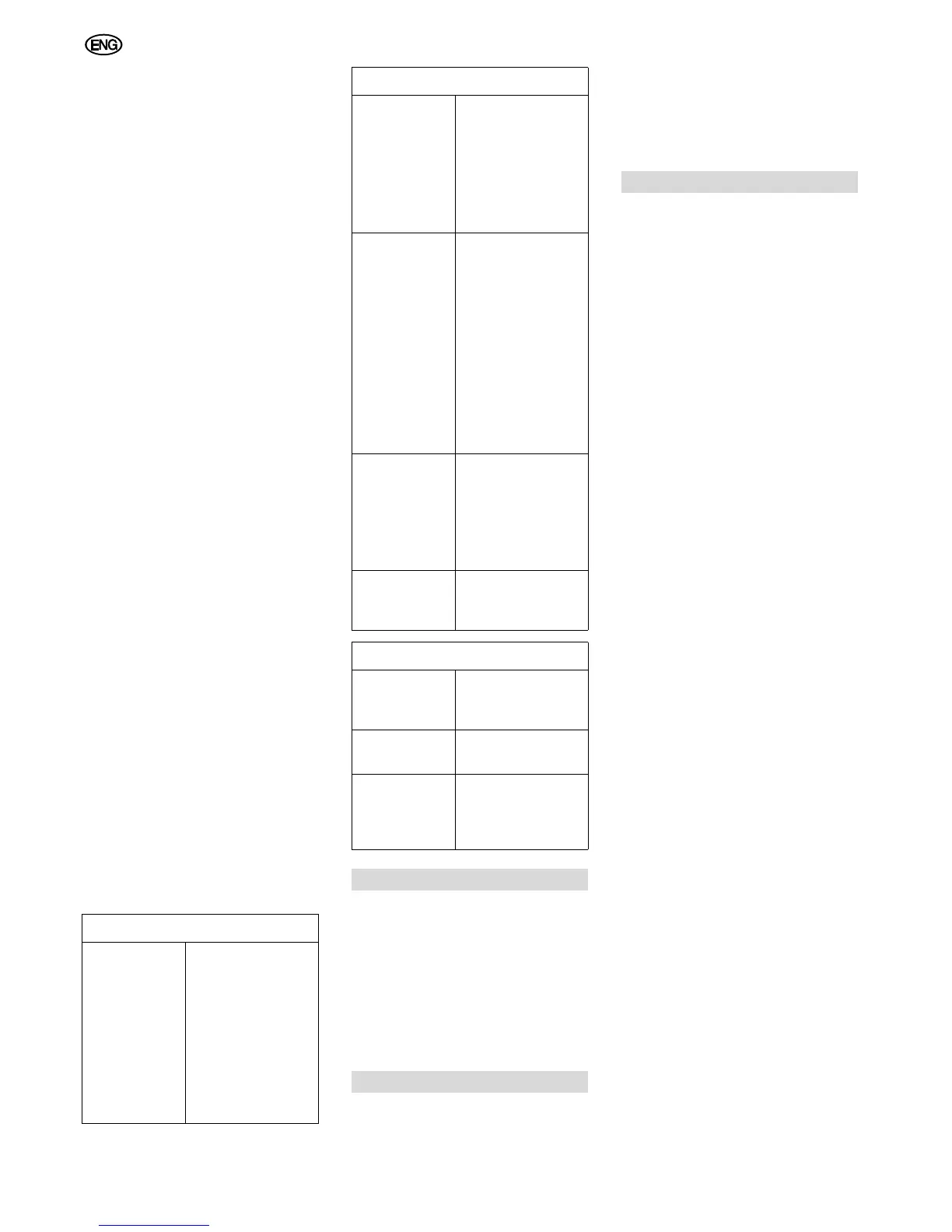

Motor does not run

• Undervoltage relay tripped by tem-

porary voltage failure.

− Start again.

• No supply voltage

− Check cables, plug, outlet and

mains fuse.

• Motor has overheated, e.g. due to

blunt planer knives, overloading or

chip buildup.

− Remove cause for overheating

and allow to cool down for

approx. 10 minutes, then start

again.

• Contact pins of outfeed table or dust

chute have not engaged in the limit

switch.

− Correctly install outfeed table or

dust chute, respectively. If neces-

sary, adjust contact pins.

Performance lessens

• Planer knives blunt

− Install sharp knives.

• Drive belt slips

− Re-tension drive belt

Planed surface not smooth

• Planer knives blunt

− Install sharp knives.

• Planer knives blocked by chips

− Remove chips.

• Moisture contents of work piece too

high

− Dry work piece.

Planed surface cracked

• Planer knives blunt

− Install sharp knives.

• Planer knives blocked by chips

− Remove chips.

• Work piece was planed against the

grain

− Plane work piece in opposite

direction

• Too much material removed in one

pass

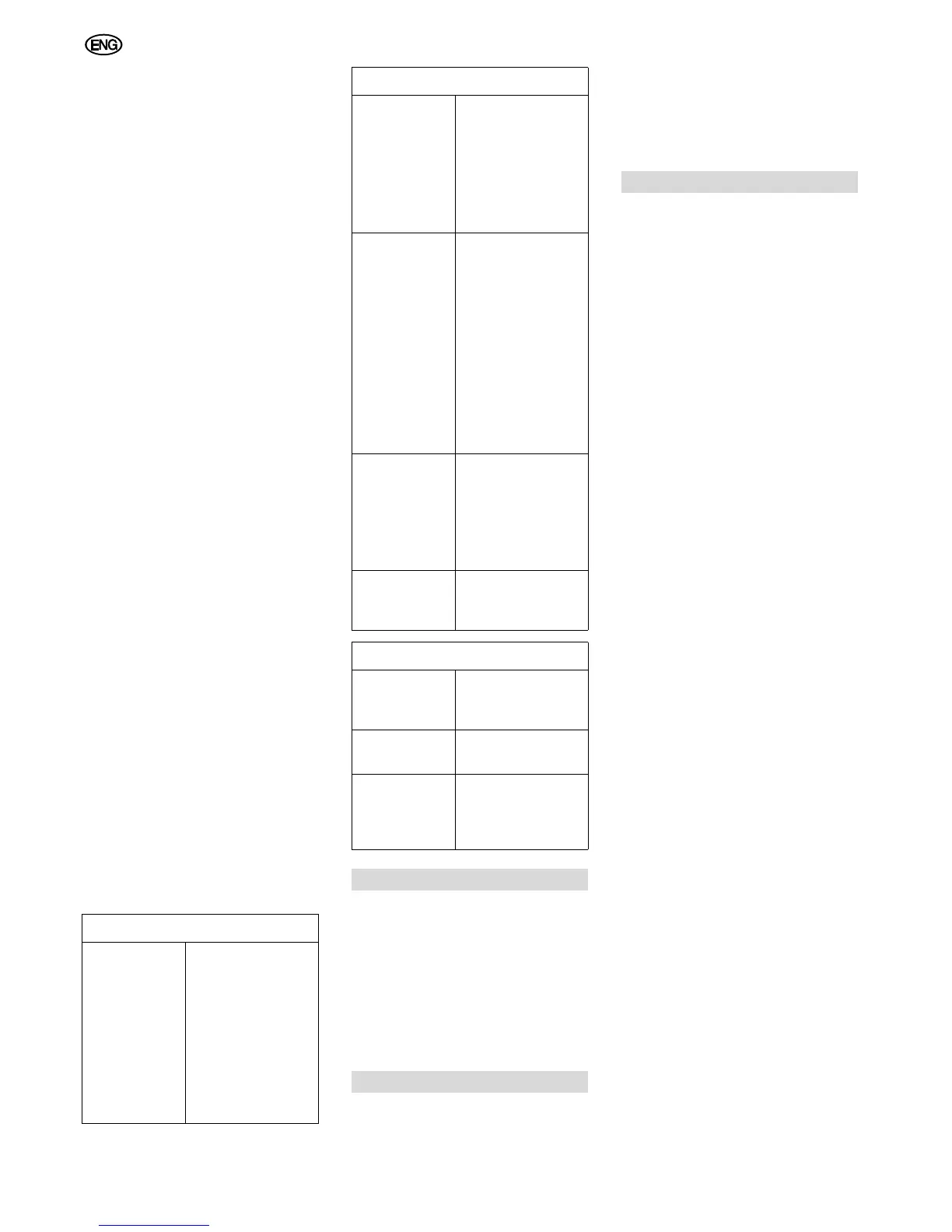

Prior to operation

Anti-kickback

lock

Check:

− mobility of anti-

kickback fin-

gers (must fall

down by their

own weight)

− points of anti-

kickback fin-

gers

(not rounded)

Planer knives Check:

− tight seat

− sharpness

− general condi-

tion

(no notches,

etc.)

Inside of

machine

Threaded rods

(height adjust-

ment)

Dust spout

(when work-

ing without

dust collec-

tion)

Remove:

− chips

− sawdust

Outfeed roller Check:

− coating undam-

aged?

− is stock prop-

erly trans-

ported?

Infeed and

outfeed table

− apply light coat

of anti-seize

compound

Monthly (if used daily)

Threaded rods

(height adjust-

ment)

Apply a light coat of

care and mainte-

nance spray

Infeed and

outfeed table

Check alignment,

correct if necessary

Power supply

cable

Check for damage,

if necessary have

replaced by a quali-

fied electrician.

8. Repairs

9. Environmental Protection

Prior to operation

10. Trouble Shooting

Loading...

Loading...