MPI – Troubleshooting

13-61

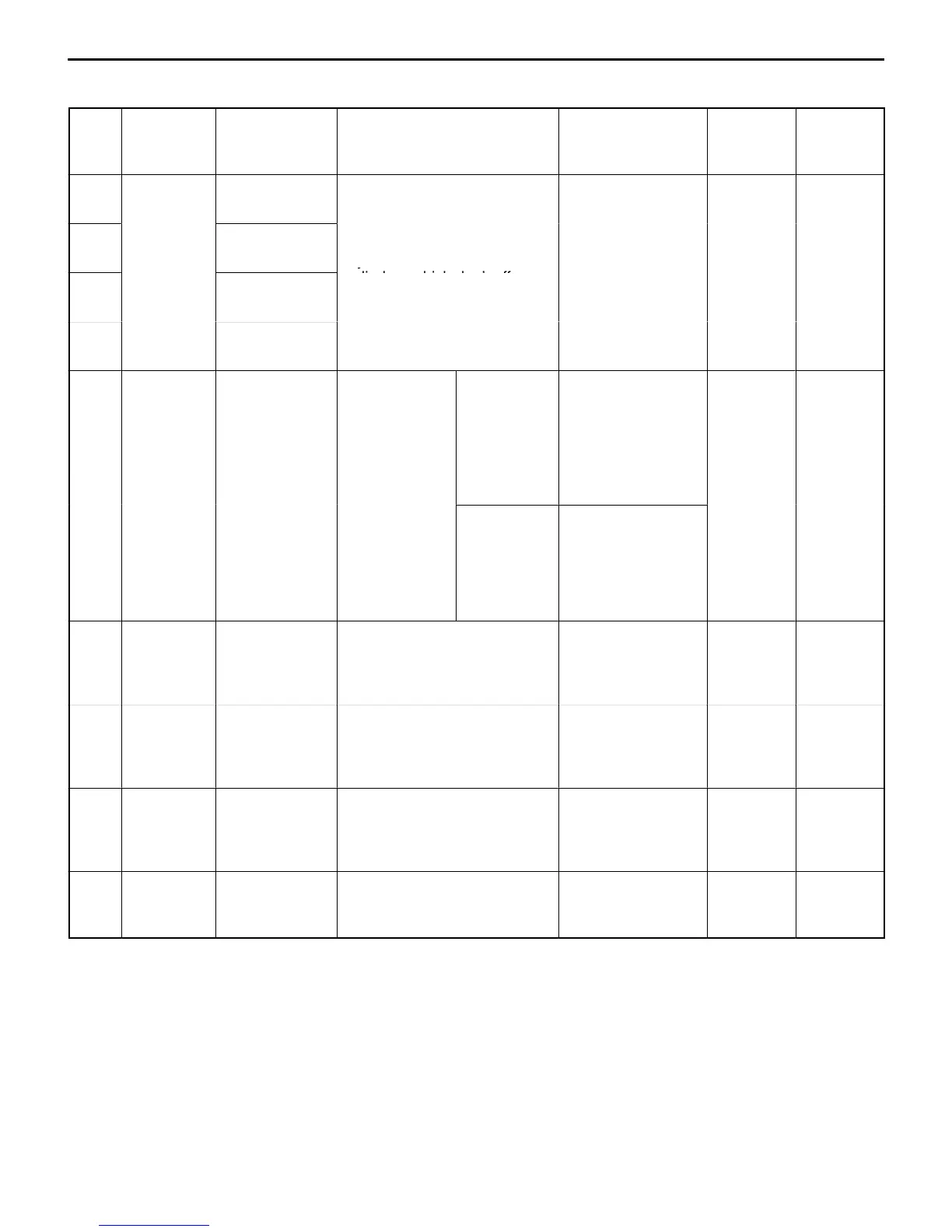

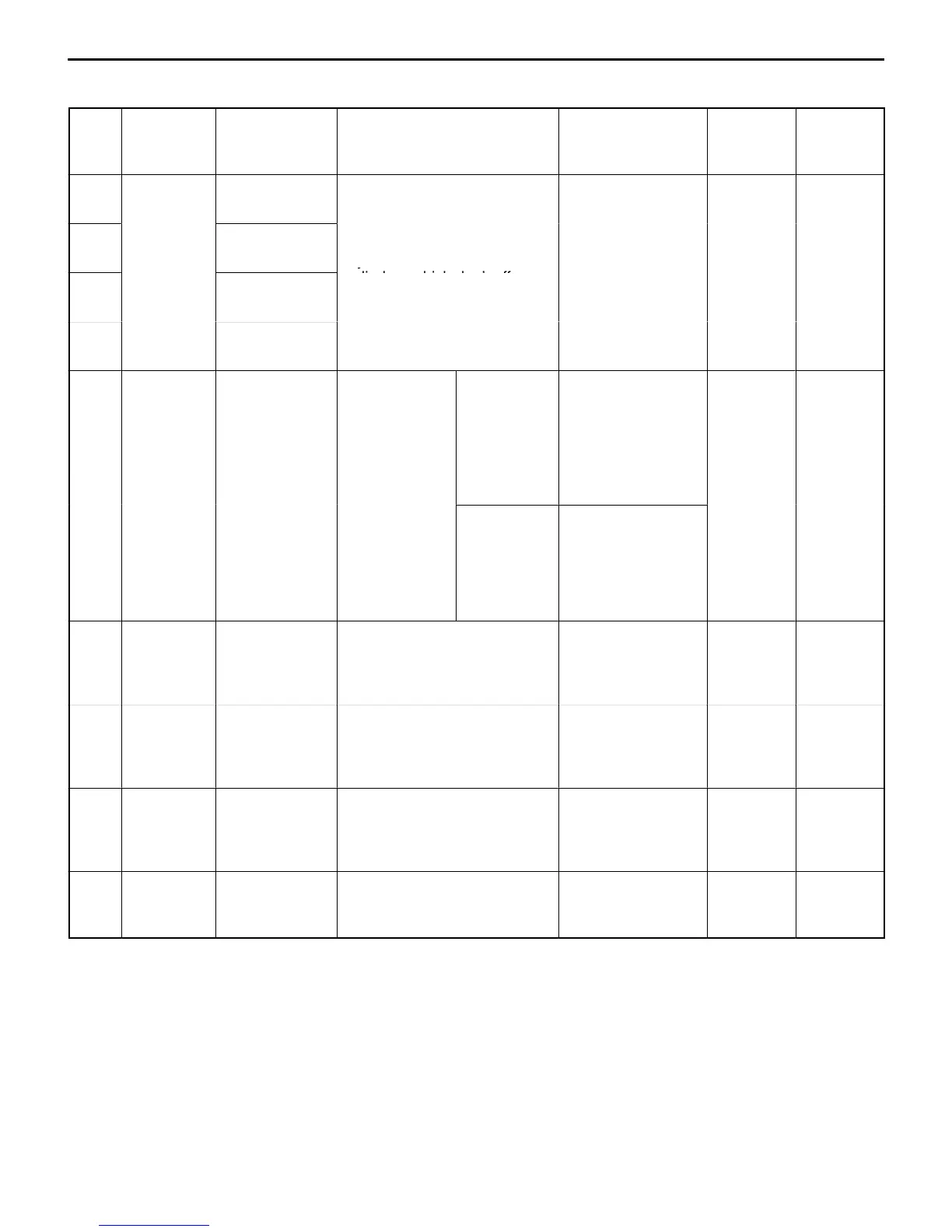

8. ACTUATOR TEST REFERENCE TABLE

Item

No.

Inspection

item

Drive contents Inspection contents Normal condition Inspection

procedure

No.

Reference

page

01 Injectors Cut fuel to No.

1 injector

Engine:

After having warmed

Idling condition

becomes different

Code No.

41

13-15

02 Cut fuel to No.

2 injector

up

ng

ne

s

ng

(Cut the fuel supply to each

injector in turn and check

ecomes uns

a-

ble, resulting in

engine stall).

03 Cut fuel to No.

3 injector

cylinders which don’t affect

idling.)

04 Cut fuel to No.

4 injector

07 Fuel pump Fuel pump

operates and

fuel is recircu-

lated.

D Engine:

Cranking

D Fuel

pump:

Forced

driving

Inspect ac-

Pinch the

return hose

with fingers

to feel the

pulse of the

fuel being

recirculated.

Pulse is felt. Procedure

No. 25

13-36

cor

ng

o

both the

above condi-

tions.

Listen near

the fuel tank

for the

sound of

fuel pump

operation.

Sound of opera-

tion is heard.

09 Fuel

pressure

control

valve

Solenoid valve

turns from

OFF to ON.

Ignition switch: ON Sound of opera-

tion can be heard

when solenoid

valve is driven.

Procedure

No. 34

13-45

12 Waste

gate

solenoid

valve

Solenoid valve

turns from

OFF to ON.

Ignition switch: ON Sound of opera-

tion can be heard

when solenoid

valve is driven.

Procedure

No. 35

13-45

13 Fuel pump

relay No.2

Turn fuel

pump relay

No.2 from

OFF to ON.

D Ignition switch: ON

D Listen to pump operation

sound near fuel tank.

Sound of opera-

tion can be heard.

Procedure

No. 25

13-36

17 Basic igni-

tion timing

Set to ignition

timing adjust-

ment mode

D Engine: Idling

D Timing light is set

5_BTDC – –

Loading...

Loading...