2205Q2JE-HO-S6-N_2020.01.

Chapter 5 Maintenance and Inspection

SCV-series Screw Compressor 5.5 Reassembly

5-40

5.5.7 Thrust Bearing Block

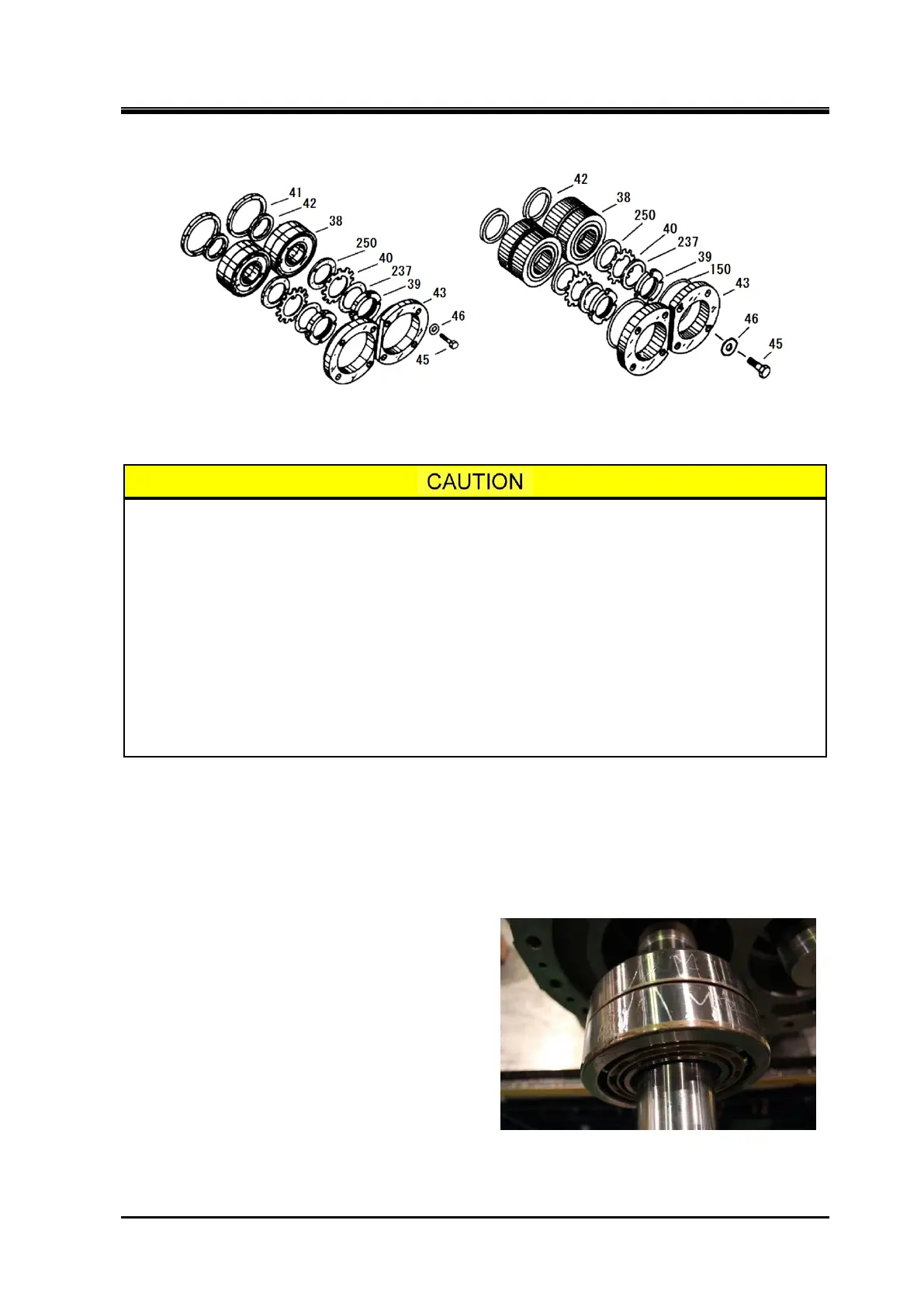

[160 to 250V**] [320V*D]

Note: 250V** models do not use the No.41.

Figure 5-15 Exploded View of the Thrust Bearing Block

The torsional slip washer [237] and lock washer [39] must be replaced with new ones.

If the removed thrust bearing is to be installed as it is, check the marking of "M" or

"F" on the thrust bearing outer race spacer [41] (160V**, 200V** models) and

alignment spacer [42], and assemble them in the same combinations as they ware

disassembled. This is important in controlling the end clearance on the discharge

side of the rotor.

Even if the same bearing is installed, the work must be very carefully done as the

dimension can change if any foreign matter such as a chip of paint or dust is pinched

by the thrust bearing outer race spacer and/or alignment spacer.

In determining the installation direction of the thrust bearing, there are two methods

depending on the existence of an alignment "V" marking on the outer circumference

of the bearing. Install the bearing according to the following procedure provided for

each case.

The assembly sequence for this part is as illustrated in Figure 5-15. The important points to be noted in

the procedure are described below:

a) Check the marking of either "M" or "F" on the thrust bearing outer race spacer and alignment spacer

to ensure that the units are assembled in the same combination of parts.

The front and back of the outer race spacer and alignment spacer must be distinguished when it is

installed. The larger chamfering side is on the machine side, and the smaller chamfering side is on

the thrust bearing side.

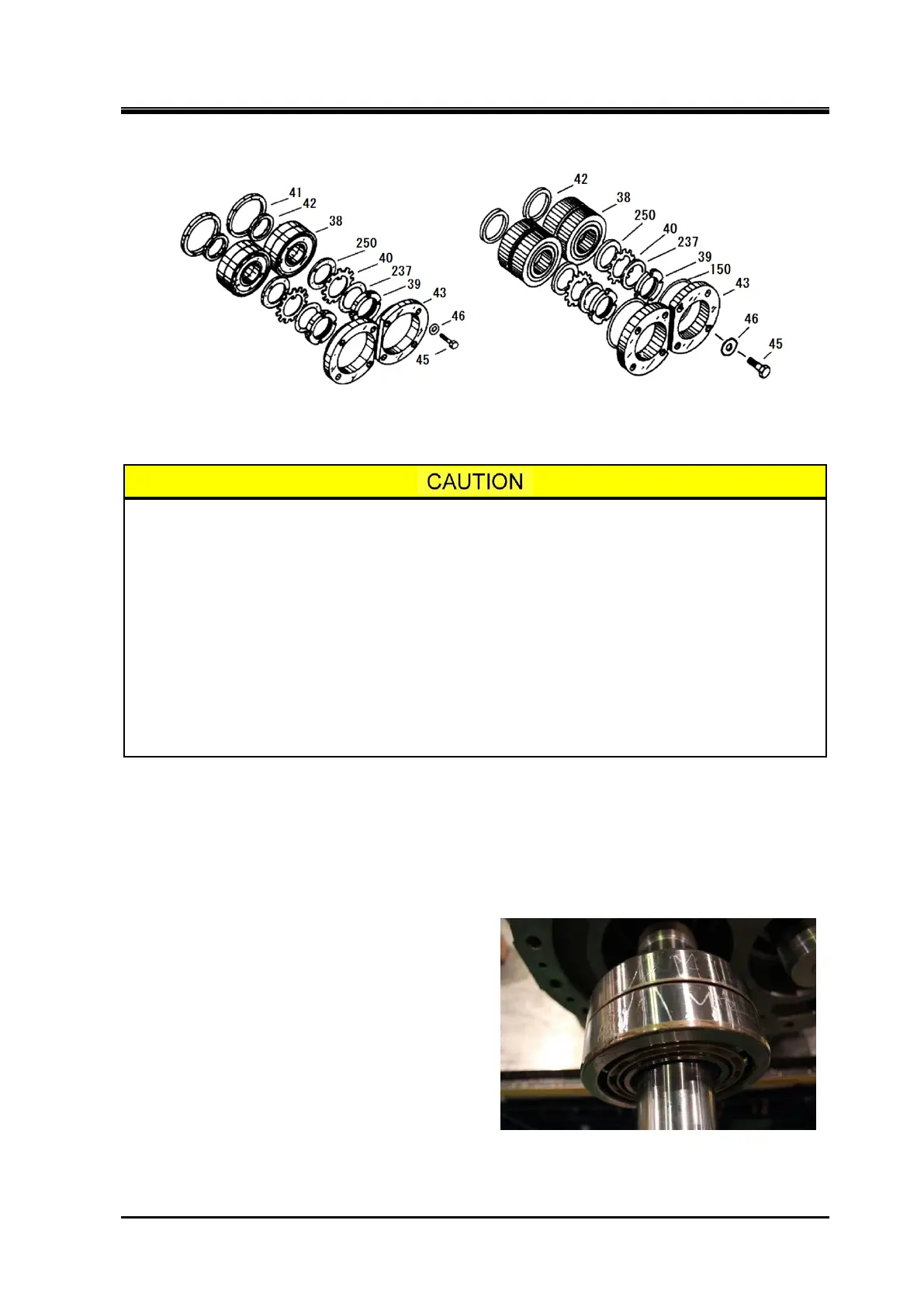

b) If thrust bearing has a "V" marking on the outer

circumference, it means that the installation

direction of the bearing will sensitively affect the

end clearance adjustment. In this case, the

bearing must be installed with the pointed end of

the marking pointed toward the inside of the

machine.

If there is no "V" marking, it means that the

direction of the bearing installation will not affect

the end clearance adjustment. However, in order

to clearly determine the orientation (whether it is

on the inside or outside of the machine), first

combine both bearings with the bearing number carving facing the outside of the machine. Then,

use a blue whetstone to write the above "V" marking on the bearing to show the inside direction of

the machine (see above picture). Then, install the bearing

Loading...

Loading...