2205Q2JE-HO-S6-N_2020.01.

Chapter 5 Maintenance and Inspection

SCV-series Screw Compressor 5.5 Reassembly

5-43

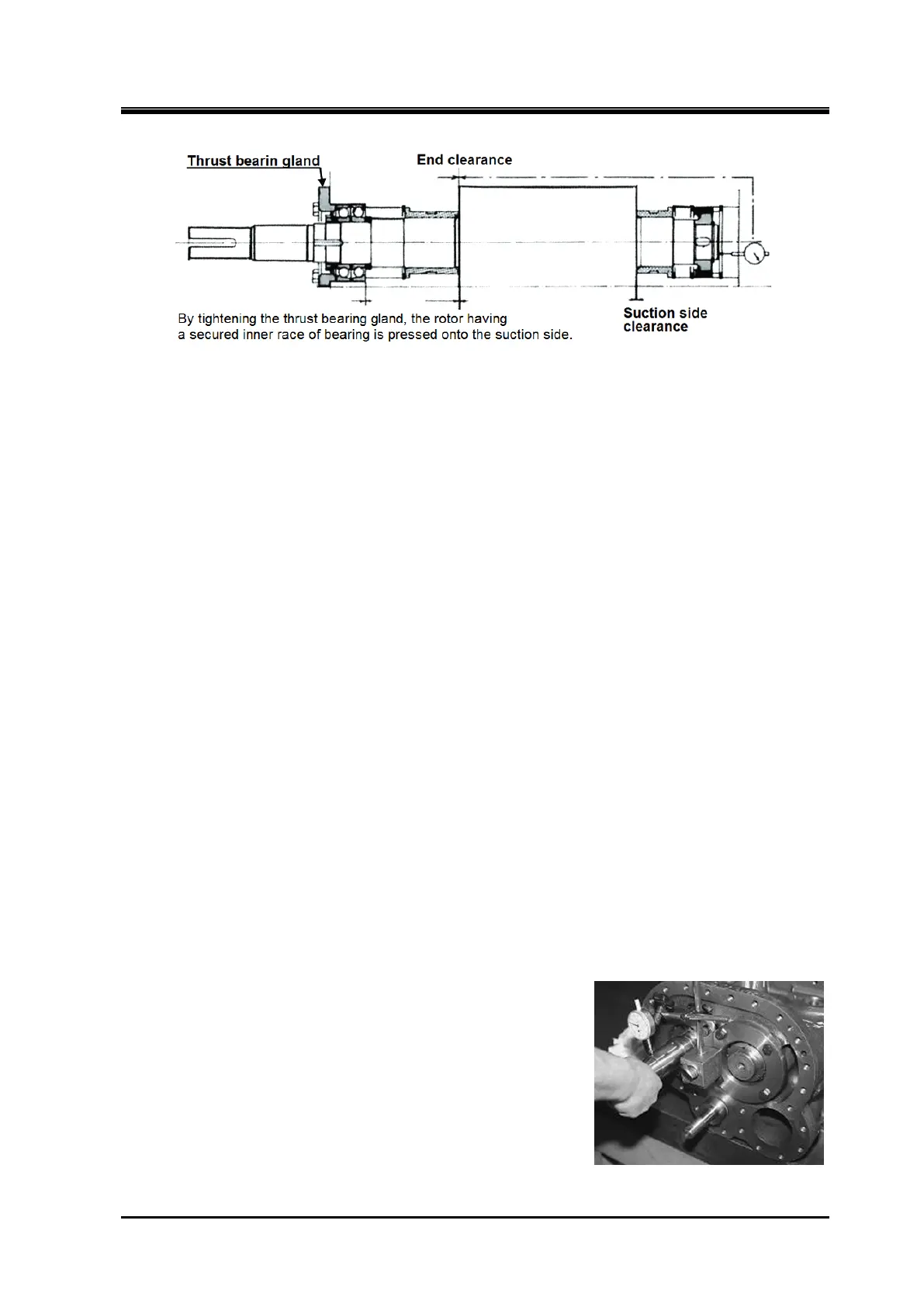

Figure 5-17 Measurement of the End Clearance

5.5.7.2 End Clearance Adjustment Procedure

(1) When the end clearance is less than the specified value

In this case, a shim (thrust adjustment liner) must be inserted between the thrust alignment

spacer [42] and the inner race of the thrust bearing to increase the end clearance.

The thickness of the shim must be determined by the difference between the specified end

clearance and the measured value.

◆ Although the thrust adjustment liner is not shown in the exploded view, you can place an

order to us indicating the model name.

Also, in case of 160V** or 200V** models, using a highly accurate surface grinding machine or

asking professional service vendors to grind, grind the surface of thrust bearing outer race

spacer [41] by the difference from the specified value.

After grinding the flat surface, measure the whole circumference of the outer race spacer by

using a micrometer, and check that the thickness is even.

(2) When the end clearance exceeds the specified value

If any shim (thrust adjustment liner) has been inserted between the thrust bearing alignment

spacer and the inner race of the thrust bearing, and the thickness corresponds to the difference

between the measured end clearance and the specified value, just remove the shim.

If no shim is used or the thickness of the shim is insufficient to compensate for the excess end

clearance, use a surface-grinding machine (or ask a vendor) to make the thrust bearing

alignment spacer [42] thinner by the amount of the end clearance difference between the

measured and specified values. After the surface grinding is done, use a micrometer to measure

the thickness of the spacer for the entire circumference to make sure the thickness is even.

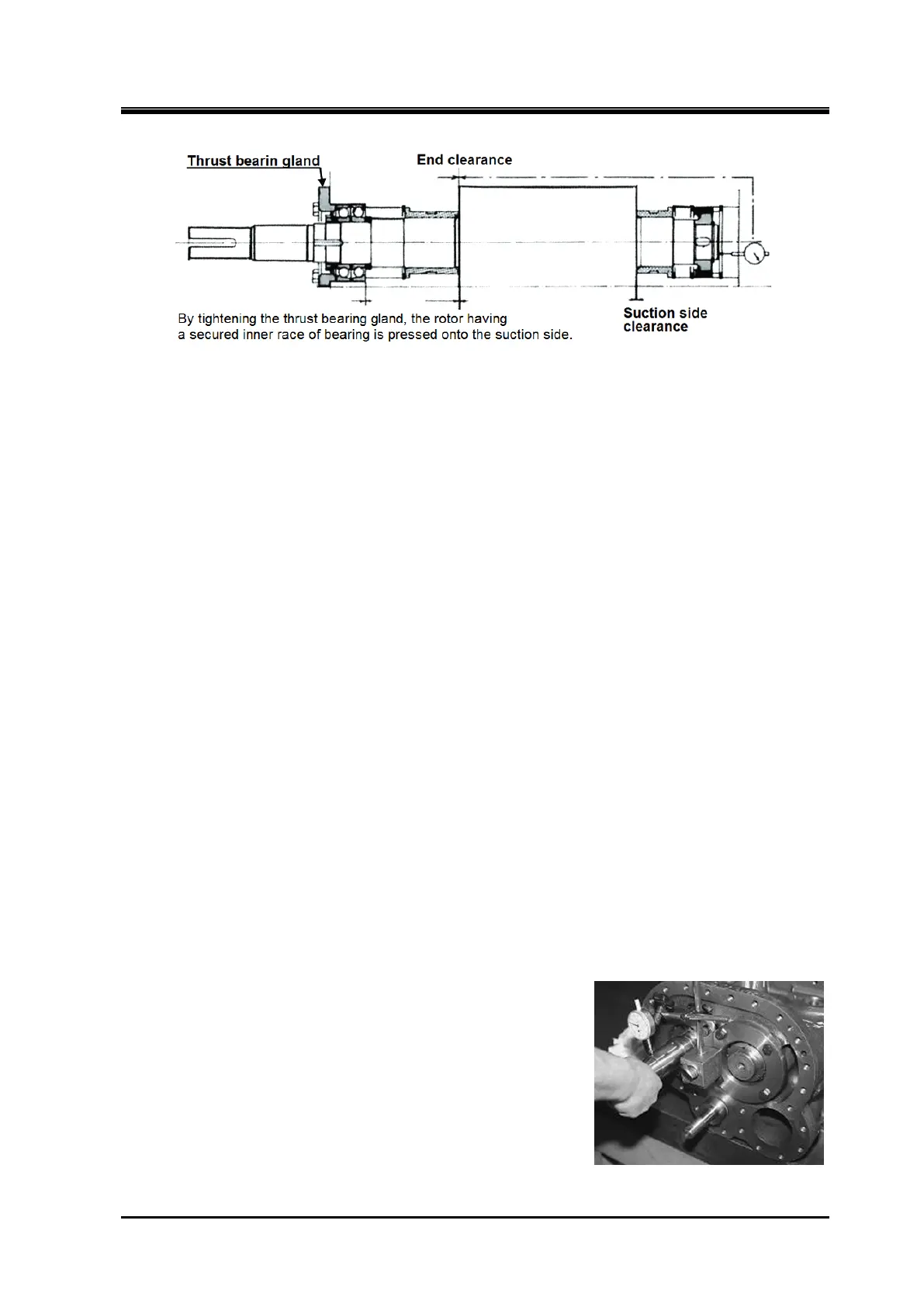

(3) Measuring the run-out of the rotor shaft

If the end clearance adjustment has been successfully completed, then measure the run-out of

the l M rotor shaft using a dial gauge at the point of the mechanical seal attachment and turning

the shaft by hand (see following picture).

A run-out of up to 0.03 mm is acceptable for all models. The run-out occurs if the thickness of the

thrust alignment spacer is not even or the marking on the

thrust bearing is not properly positioned. And it occurs if

fastening the lock nut performed without changing the

position of the lock nut wrench, . The run-out also becomes

significant if any small foreign matter is present in between

relevant parts.

If the run-out exceeds the allowable value, disassemble this

block again even if the end clearance is within the specified

limits, and adjust the relative position of the outer race

spacer, alignment spacer and thrust bearing.

This adjustment is very important as any run-out affects the

function and service life of the mechanical seal.

Loading...

Loading...