2205Q2JE-HO-S6-N_2020.01.

Chapter 5 Maintenance and Inspection

SCV-series Screw Compressor 5.4 Disassembly and Inspection

5-17

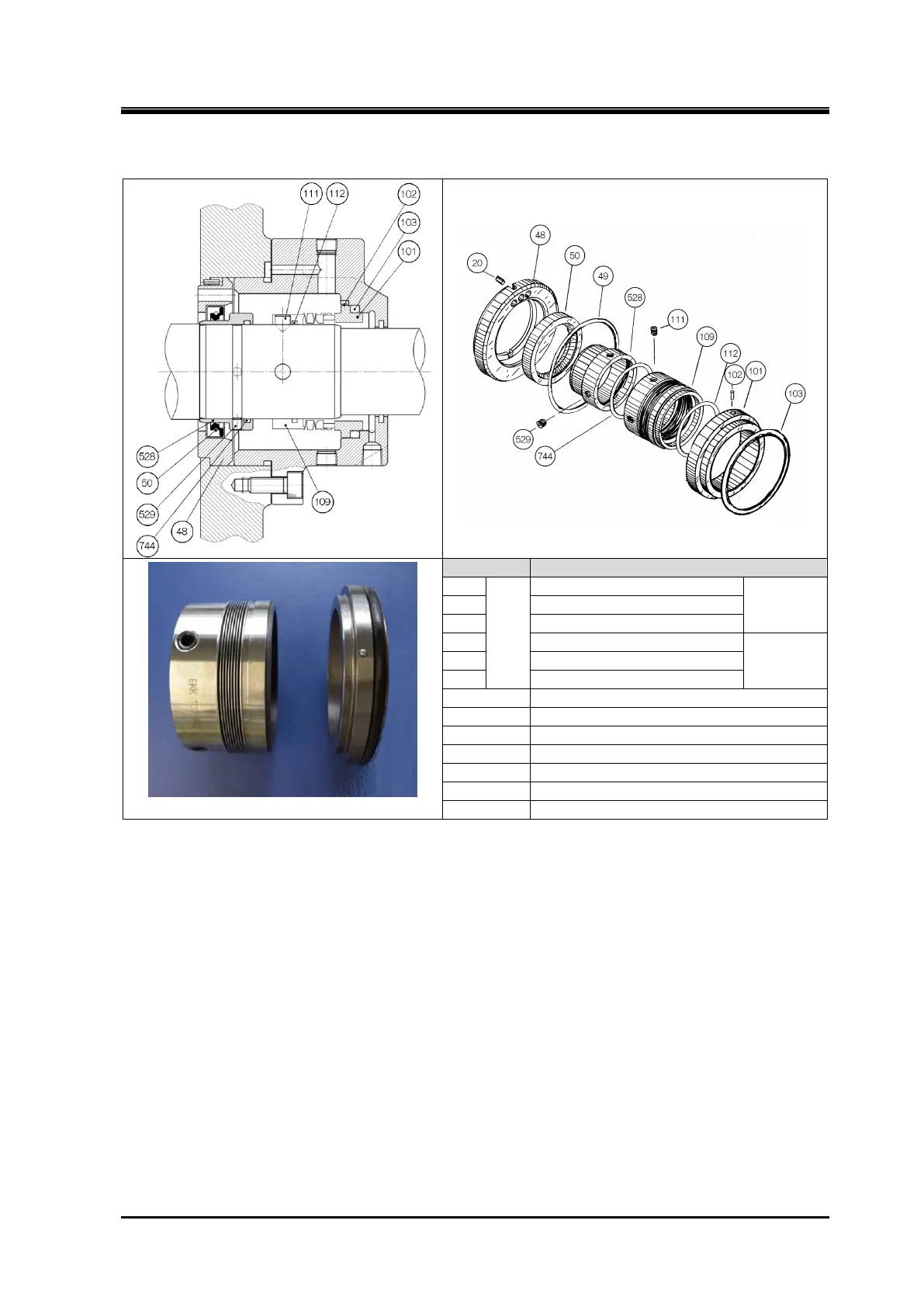

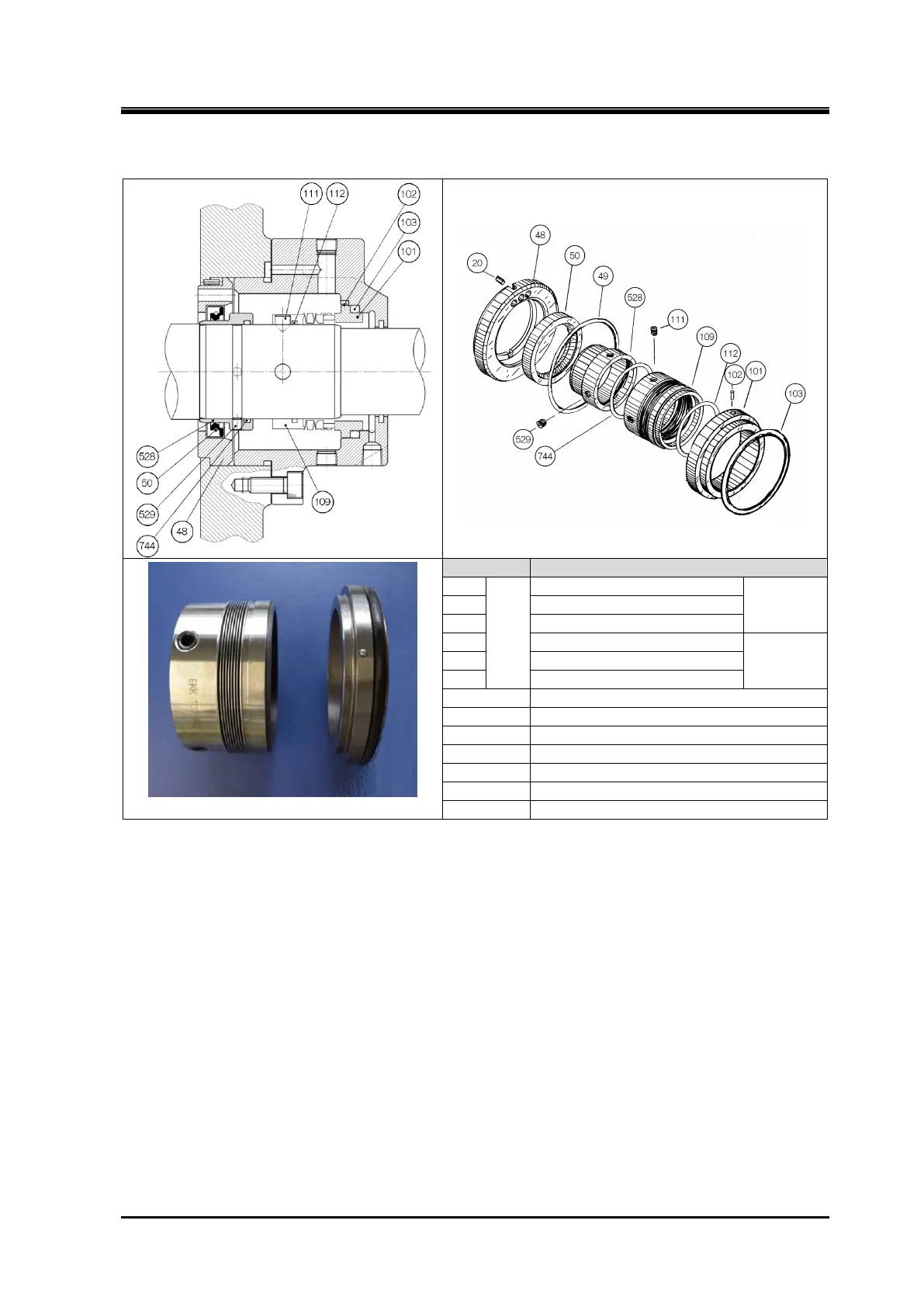

5.4.2 Shaft Seal Block

Mechanical Seal assembly

100

Stationary

rings

Rotating

rings

Set screw for oil seal sleeve

Note: [528], [529], [744] are not used to 160V** models.

Figure 5-5 Details of BBSE-type Mechanical Seal Assembly and Related Parts

5.4.2.1 Disassembly

a) Of the eight hexagon socket head cap screws [53] securing the seal cover [51], remove six bolts

leaving two diagonally opposite bolts.

b) Loosen the remaining two screws alternately and evenly, a little at a time. When the screws are

loosened to some extent, the seal cover will be pushed by the spring force of the seal to create a

gap under the cover. The gap will not be created if the gasket is sticking to both surfaces. In this

case, free the cover by screwing M8 eye bolts into the jacking screw threads on the seal cover to

separate it.

c) As the oil inside will flow out through the gap, be ready to receive the oil with a container.

d) Pull out the seal cover in the direction of the rotor shaft axis. Inside the cover, there is the mating

ring fitted with the O-ring. In this, carefully remove the seal cover for the mating ring not to be

damaged by touching the shaft.

e) Remove the O-ring [49] between the seal cover and oil seal retainer [48].

Loading...

Loading...