2205Q2JE-HO-S6-N_2020.01.

Chapter 5 Maintenance and Inspection

SCV-series Screw Compressor 5.4 Disassembly and Inspection

5-28

5.4.8 Thrust Bearing Block

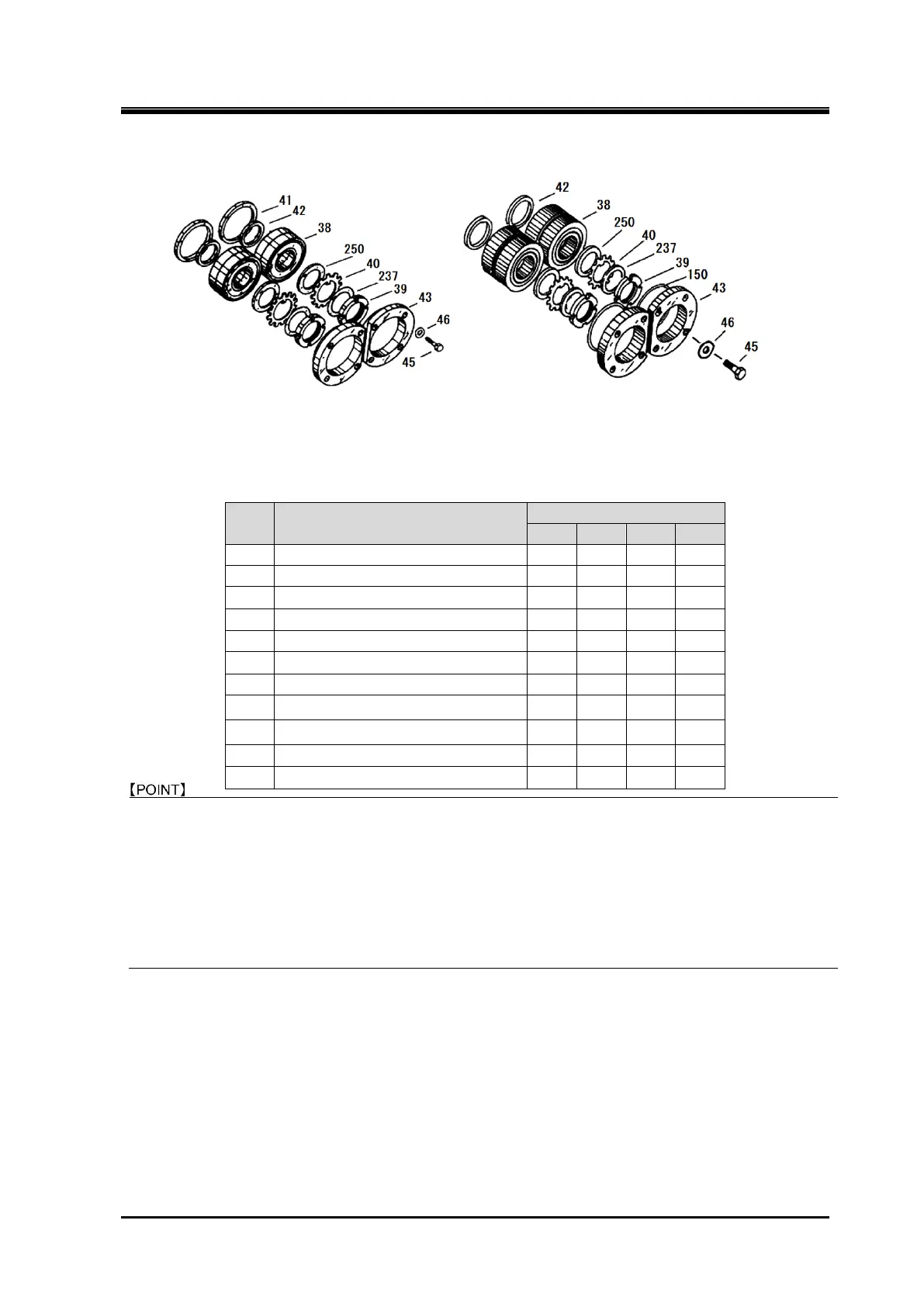

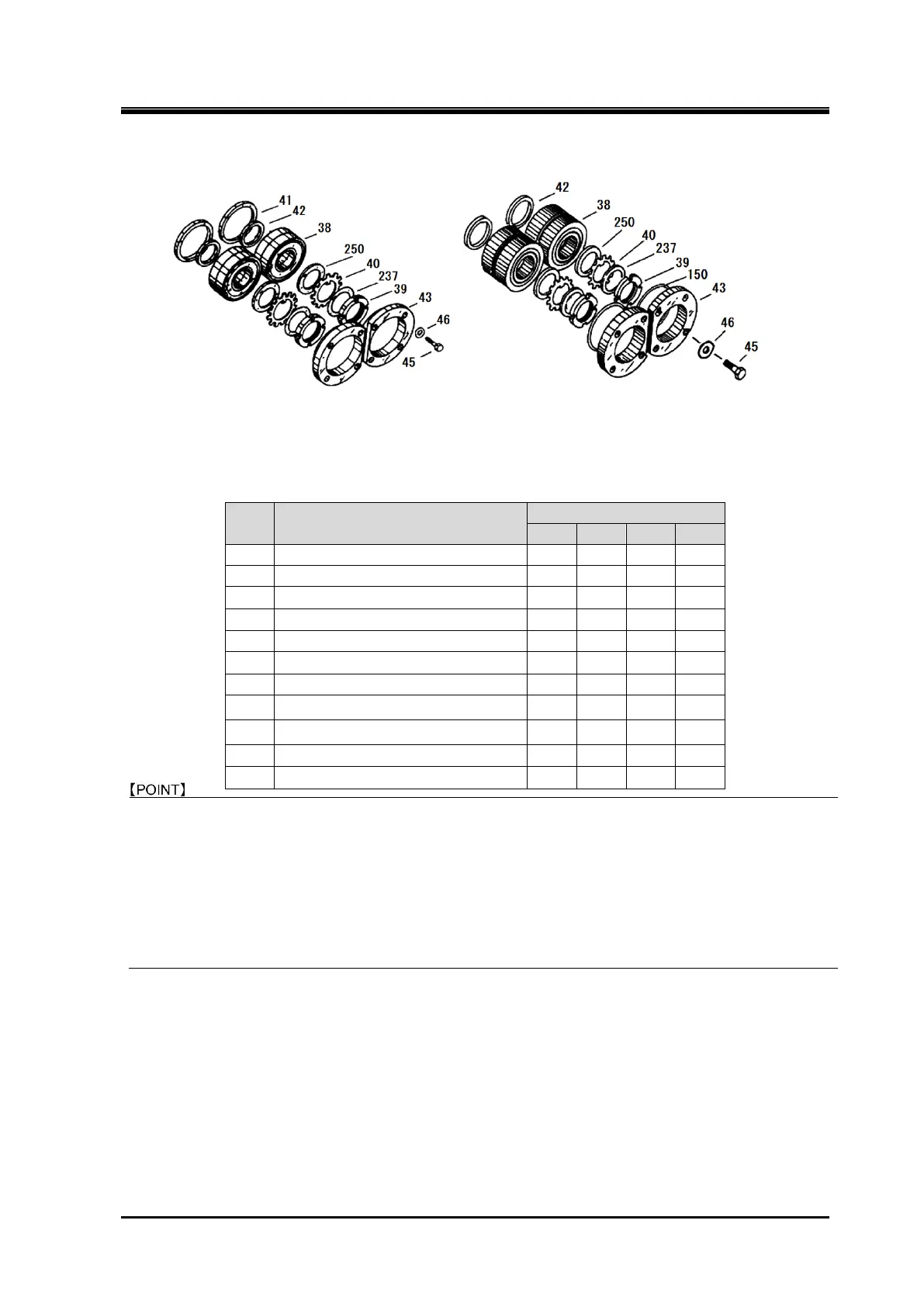

[160 to 250V**] [320V*D]

Figure 5-12 Exploded Views of Thrust Bearing Block

Table 5-7 Parts Configuration of Thrust Bearing Block

●

The thrust bearing block of 250V** models and 320V*D models have no spacer for the thrust bearing

outer race. While the thrust bearing outer race spacer [41]

is used to support (i.e., ensure a sufficient

support width for) the outer race of the thrust be

aring, 250 or higher models use no spacer for the

thrust bearing outer race because the bearing head has sufficient margin to the support it.

● The thrust bearing block of 320V*D models is using an oil supply spacer

for the combined surface.

This is to facilitate lubrication of the ball bearing because as the rotor

diameter becomes larger, the

rotor shaft diameter become larger. Thus, a larger thrust bearing is

required and the ball rotation

speed increases accordingly.

●

Only 320V*D models employ O-ring [150] to thrust bearing gland.

5.4.8.1 Disassembly

a) Remove the lock nut [39] that has been loosened. Then, remove the torsional slip washer [237], lock

washer [40], and thrust washer [250].

b) The clearance fit is applied to two gaps between the outer race of the thrust bearing and the bearing

head, between the inner race of the thrust bearing and the rotor shaft.

Prepare a 1 or 2 mm diameter wire, make the tip of the wire flat by hammering, and slightly bend the

tip to make a hook. Then, insert the tip of the wire between the outer race and the ball retainer of the

thrust bearing [38] to hook and pull out the bearing. In this way, the bearing can be easily removed.

P/N Part Name

41

Spacer, Thrust bearing outer race

2 - -

Spacer, Thrust bearing alignment

43

2 2 2

46

Conical spring washer 8

8 8 8

150

O-ring -

- - 2

250

2 2 2 2

Loading...

Loading...