2205Q2JE-HO-S6-N_2020.01.

Chapter 5 Maintenance and Inspection

SCV-series Screw Compressor 5.5 Reassembly

5-52

j) Apply oil on the seal cover gasket [52] and attach it to the seal cover flange by carefully aligning the

oil hole position on the gasket and the one on the flange.

◆ In case of the standard internal oil supply system for the shaft seal block, oil is first sent from the

bearing cover to the seal cover through the oil supply hole machined on them, then from the

notch in the seal cover to the upper part of the seal cover through a groove, and lastly supplied

from the oil supply hole in the seal cover to the upper part of the sliding surface of the

mechanical seal.

k) Apply and flow sufficient lubricating oil on the sliding surface of the mechanical seal assembly.

m) Install the seal cover with the gasket such that the oil drop tube comes to the bottom side.

At this time, carefully install the seal cover not to hit the mating ring in the seal cover with the rotor

shaft. For this, hold the seal cover at the right angle to the rotor shaft or only slightly incline it such

that the top side follows the bottom side.

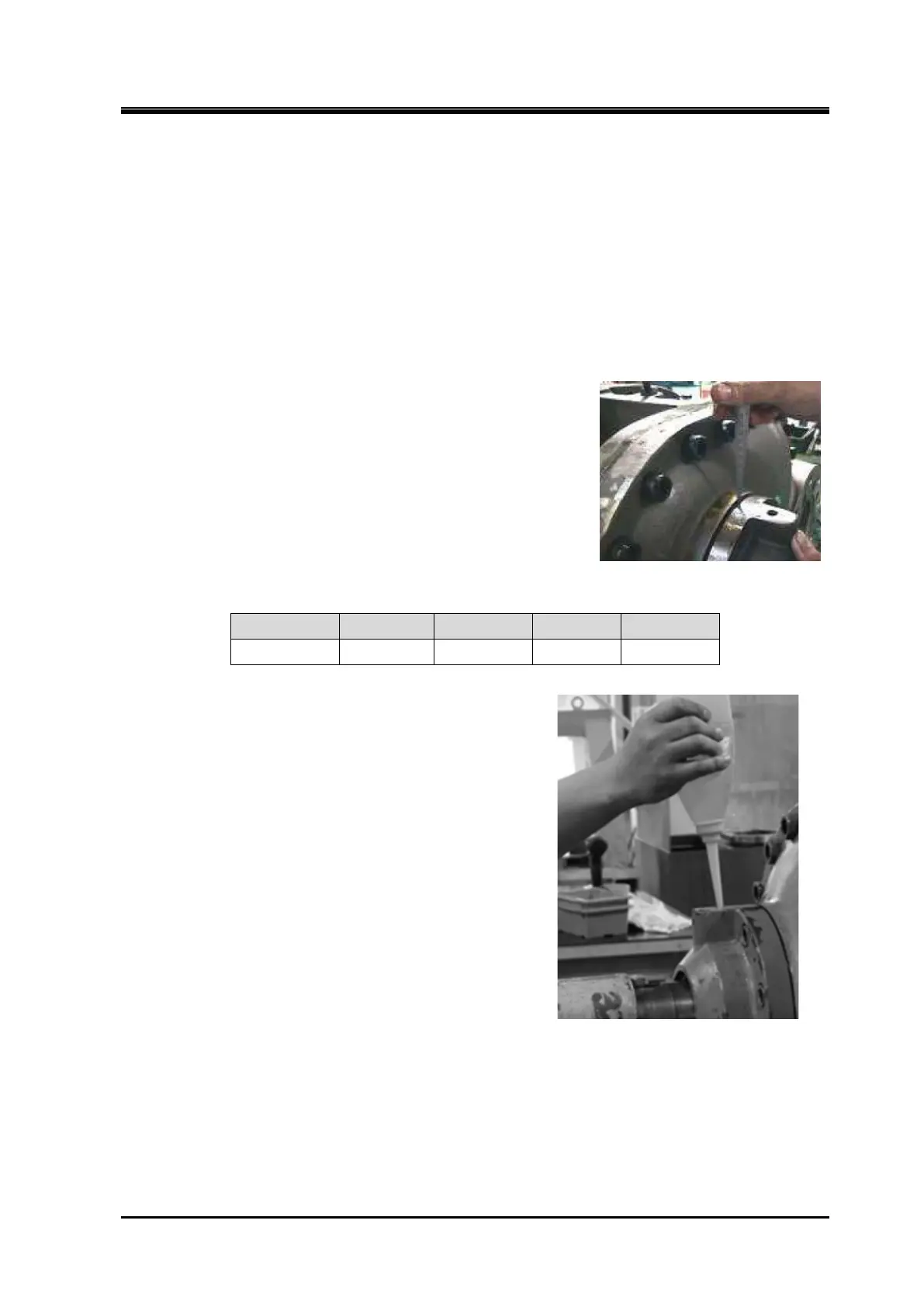

n) At a midway point, the sliding surface of the seal ring comes in

contact with that of the mating ring. At this point, use a taper

gauge (right picture) to check the clearance between the

surfaces of the seal cover gasket and the bearing cover flange.

This clearance is called "fastening margin" of the seal, and is

used as a guideline in determining the sliding surface pressure

between the rotating ring and stationary ring of the seal. In case

of the BBSE type seals for SCV-series, make sure that this

value is in the range shown in Table 5-12.

Table 5-12 Fastening Margin of the Seal

(mm)

o) If it is confirmed that the fastening margin of the seal is

appropriate, firmly press the seal cover onto the bearing

cover. While you will feel the reaction of the seal bellows,

keep pressing the cover and fasten two hexagon socket

head cap screws [53] evenly to secure the seal cover at

opposite positions separated by 180°. When there is no

clearance between the surface of the flange and gasket,

tighten all other bolts at the specified torque.

p) After tightening the seal cover, supply oil into the seal

cover while rotating the rotor shaft (right picture).

After this, do not forget attaching the plug for the oil

supply hole of the seal cover.

Loading...

Loading...