8

23

22

16

15

17

5423

RX

1

FOTO 2

TX

21

16

23

15

17

13

14

4231

RX

5

14

13

TX

21

FOTO 2

RX

54231

16

FOTO

TX

21

23

22

16

15

4231

RX

5

17

15

22

17

13

14

13

23

13

23

14

13

TX

21

FOTO

16

15

23

17

22

16

15

17

13

14

14

13

4231

RX

5

4231

RX

5

TX

21

TX

21

FOTO 2

FOTO

12 43251

5431221

17

22

23

16

15

RX

RXTX

TX

FOTO

FOTO 2

14

13

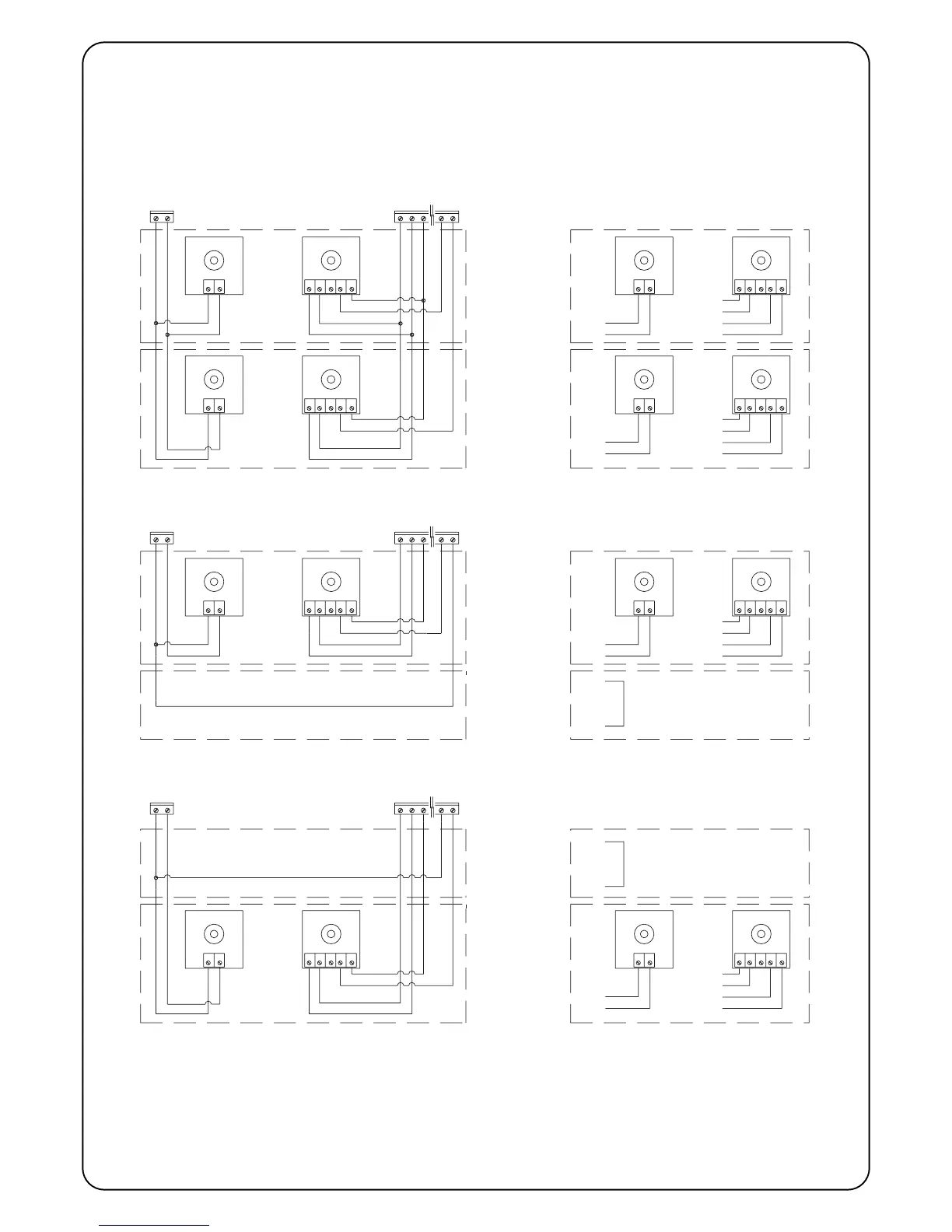

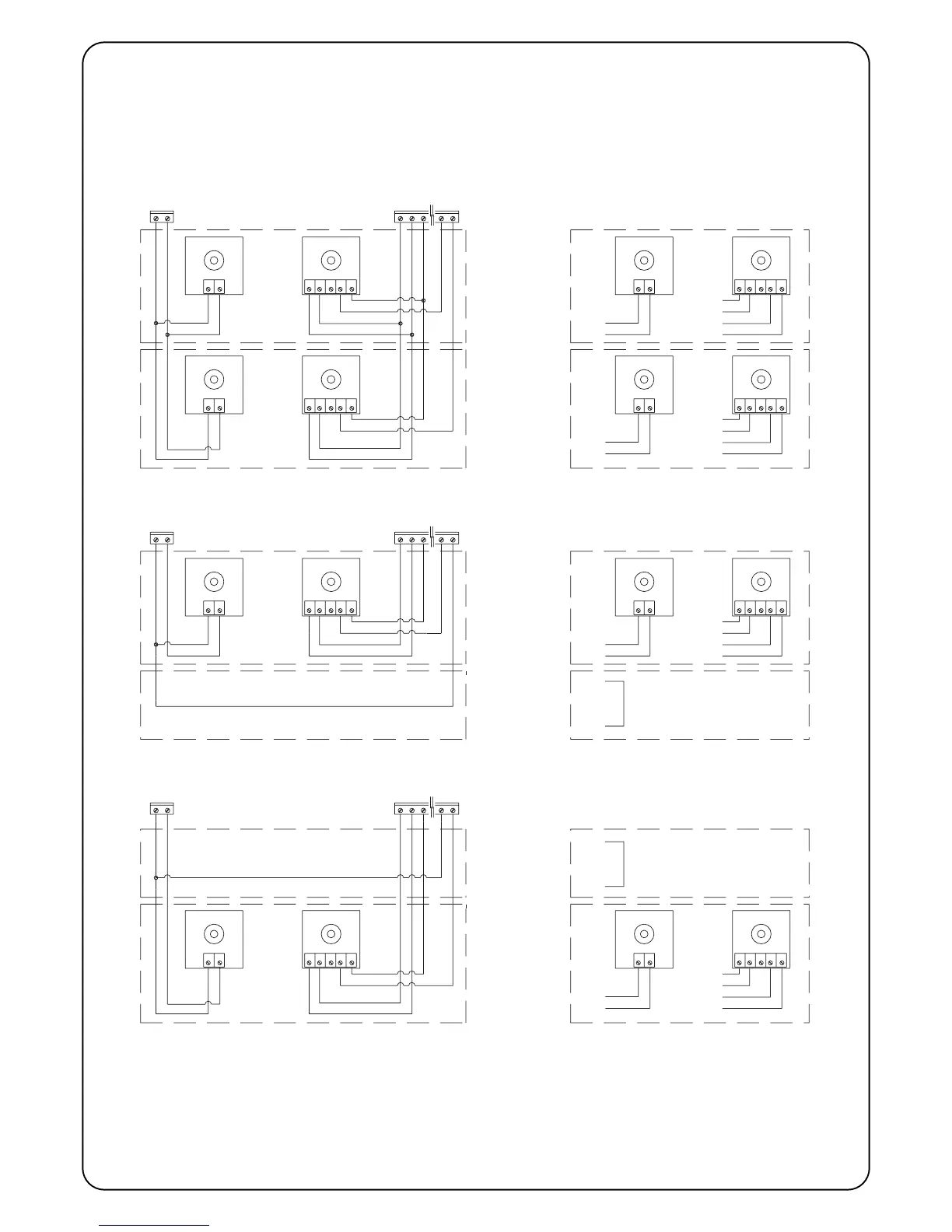

2.6) Phototest

The “Phototest” function is an excellent solution as regards the reli-

ability of safety devices and puts the control unit and photocell

assembly into category 2 as per UNI EN 954-1 standard (ed.

12/1998).

In order to implement this solution, connect the photocells as shown

in one of the figures 3A, 3B or 3C, and move Dip-Switch 7 to On

(activate “Phototest”).

Fig. 3A Shows how to connect Phototest with the Photo and Photo2 photocells

Fig. 3B Shows how to connect Phototest with just the Photo photocell

Fig. 3C Shows how to connect Phototest with just the Photo 2 photocell

When movement is required, the unit first check that all the receivers

involved give their consent, then it turns off the phototest output

after which it checks that all the receivers signal the fact by remov-

ing their consent; the phototest output is finally reactivated and the

consent of all the receivers is verified once more. If a faulty device or

a shorted cable, etc., is detected during the above sequence, the

manoeuvre is not carried out.

PHOTO

PHOTO 2

PHOTO

PHOTO PHOTO

PHOTO 2

PHOTO 2 PHOTO 2

Loading...

Loading...