Wear limits:

Max. 1.6 mm.

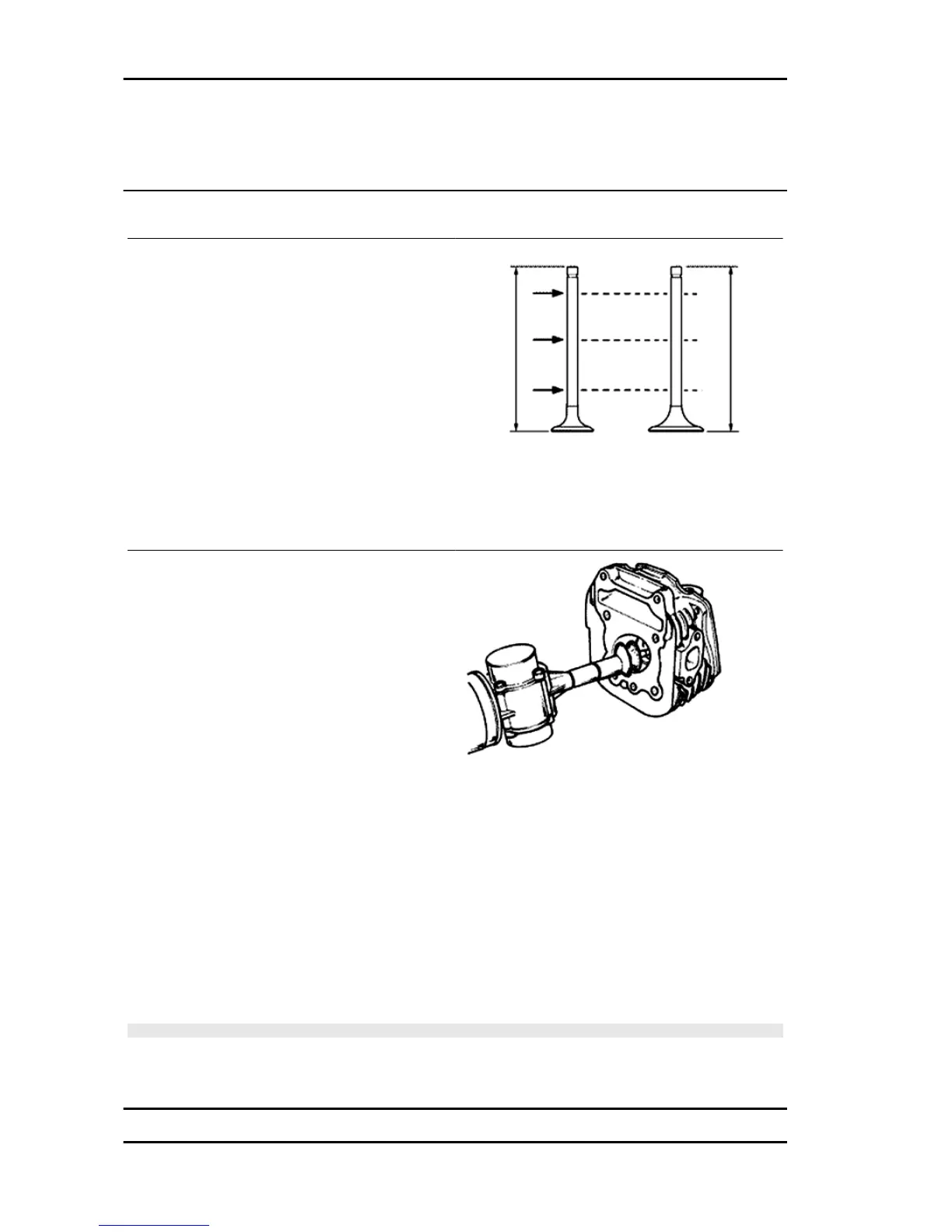

Inspecting the valves

- Measure the diameter of the valve stems in the

three positions indicated in the diagram.

- Calculate the clearance between the valve and

the valve guide.

Characteristic

Minimum diameter allowed: Intake

4.970 mm

Minimum admissible diameter drainage

4.960 mm

Fitting clearance

Standard clearance: Intake 0.015 ÷ 0.042 mm

Standard clearance: drainage 0.025 ÷ 0.052 mm

- Check that there are no signs of wear on the

contact surface with the articulated register termi-

nal.

- If the sealing surface on the valves is wider than

the specified limit, damaged in one or more points

or curved, replace the valve with a new one.

Characteristic

Valve standard length: Intake

70.1 mm

Valve standard length: drainage

69.2 mm

Fitting clearance

Max. clearance allowed: Intake 0.052 mm Max.

clearance allowed: drainage 0.062 mm

- If the checks above give no failures, you can use the same valves. For best sealing results, it is

advisable to grind the valves. Grind the valves gently with a fine-grained lapping compound. During

grinding, keep the cylinder head in a horizontal position. This will prevent the lapping compound resi-

dues from penetrating between the valve stem/guide coupling.

CAUTION

TO AVOID SCORING THE CONTACT SURFACE, DO NOT KEEP ROTATING THE VALVE WHEN

NO LAPPING COMPOUND IS LEFT. CAREFULLY WASH THE CYLINDER HEAD AND THE

VALVES WITH A SUITABLE PRODUCT FOR THE TYPE OF LAPPING COMPOUND BEING USED.

Engine MSS ZIP 100 4T

ENG - 100

Loading...

Loading...