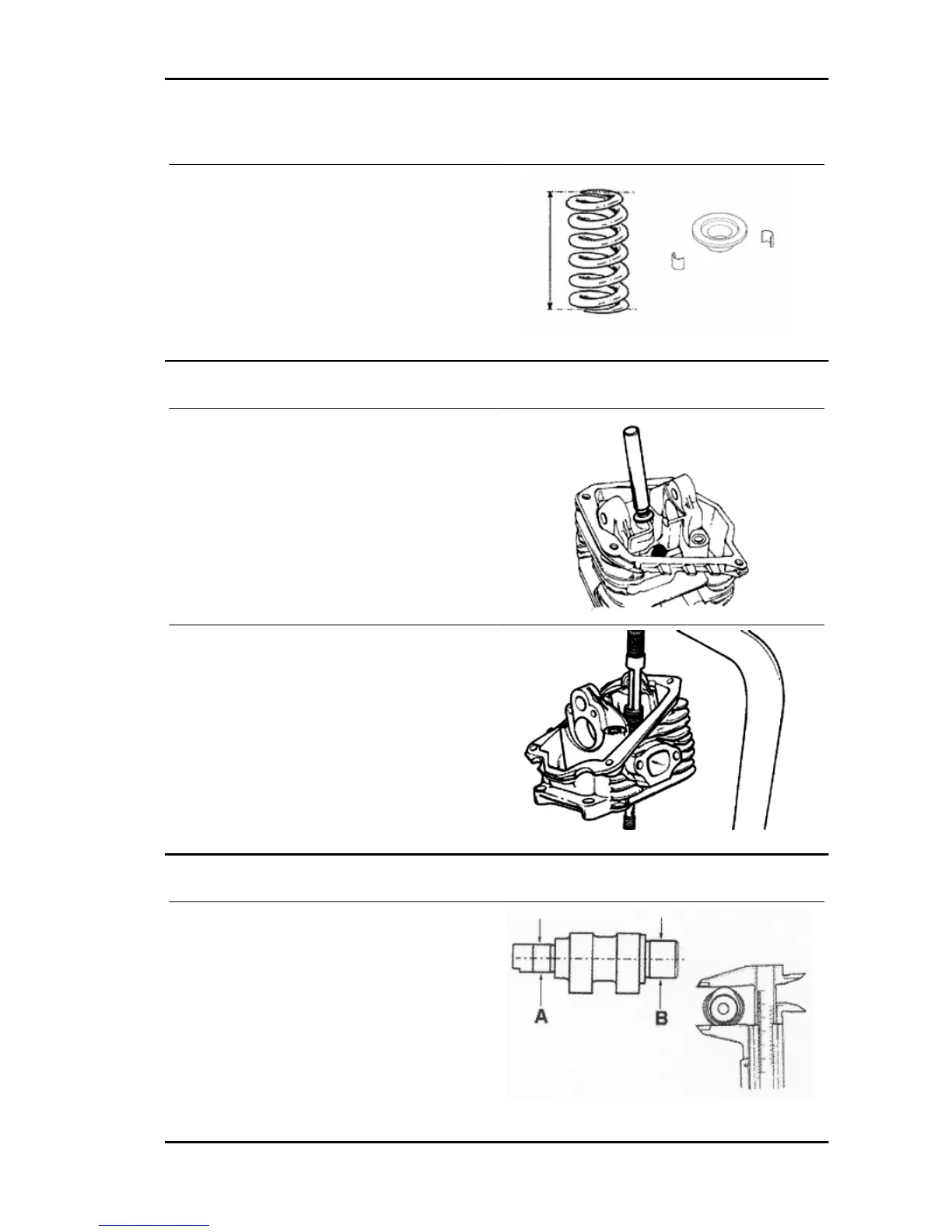

Inspecting the springs and half-cones

- Check that the upper spring caps and the cotter

halves show no signs of abnormal wear.

Refitting the valves

- Lubricate the valve guides with graphite grease.

- Place the lower plates of the valve spring on the

head.

- Use the punch to fit the 2 sealing rings one at a

time.

Specific tooling

020306Y Punch for assembling valve seal

rings

- Fit the valves, the springs and the upper caps.

- Using the appropriate tool, compress the springs

and insert the cotters in their seats.

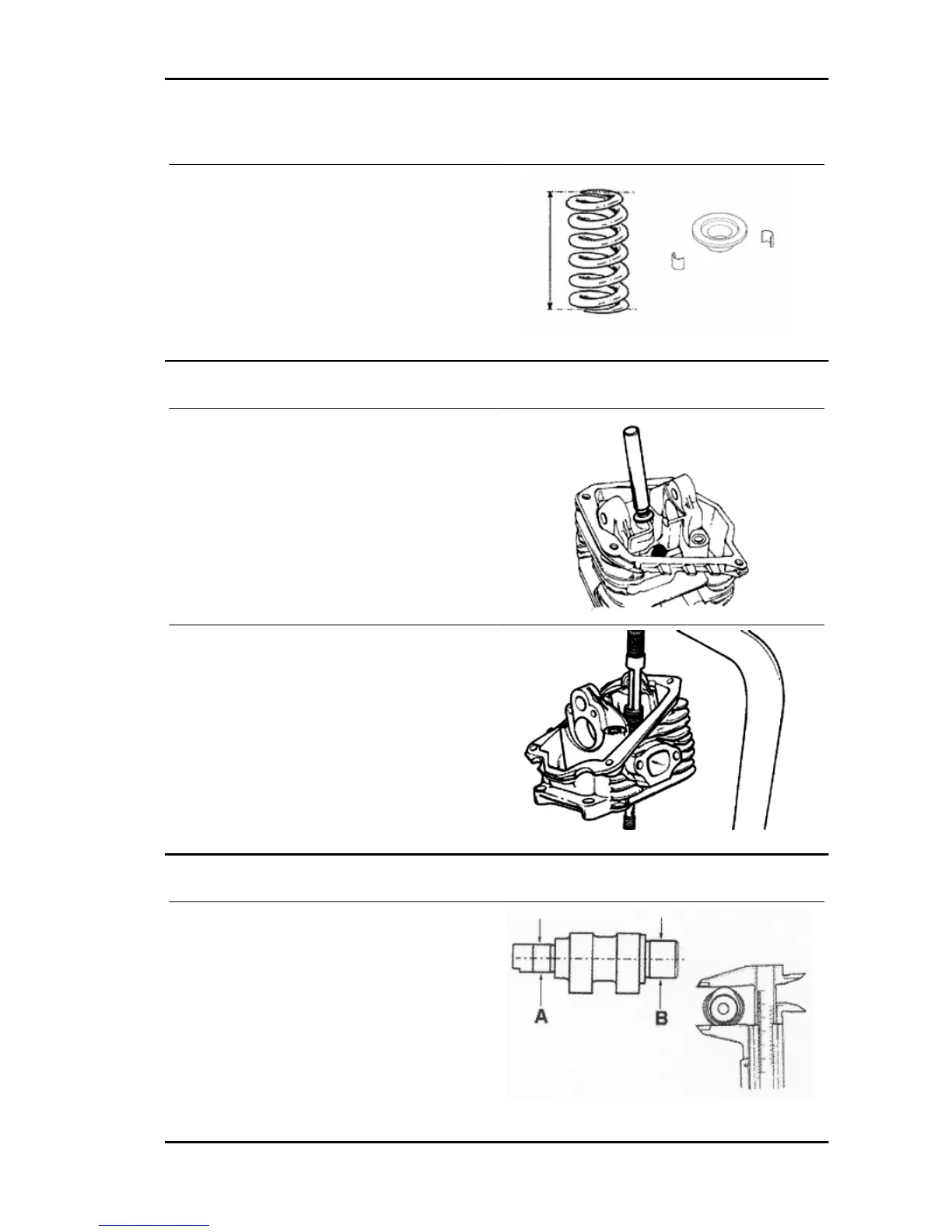

Inspecting the cam shaft

- Inspect the cam shaft for signs of abnormal wear

on the cams.

Characteristic

Standard diameter - Bearing A:

Ø 12 +0.002 +0.010

mm Standard diameter - Bearing B:

Ø 16-0.015 -0.023 mm

Minimum diameter allowed - Bearing A:

MSS ZIP 100 4T Engine

ENG - 101

Loading...

Loading...